Multi-cavity integrated combustor

An integrated, burner technology, applied in burners, gas fuel burners, combustion methods, etc., can solve the problems of gas waste, limited change range, small adjustment range, etc., to avoid flames with different lengths and avoid burning Insufficient effect of improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

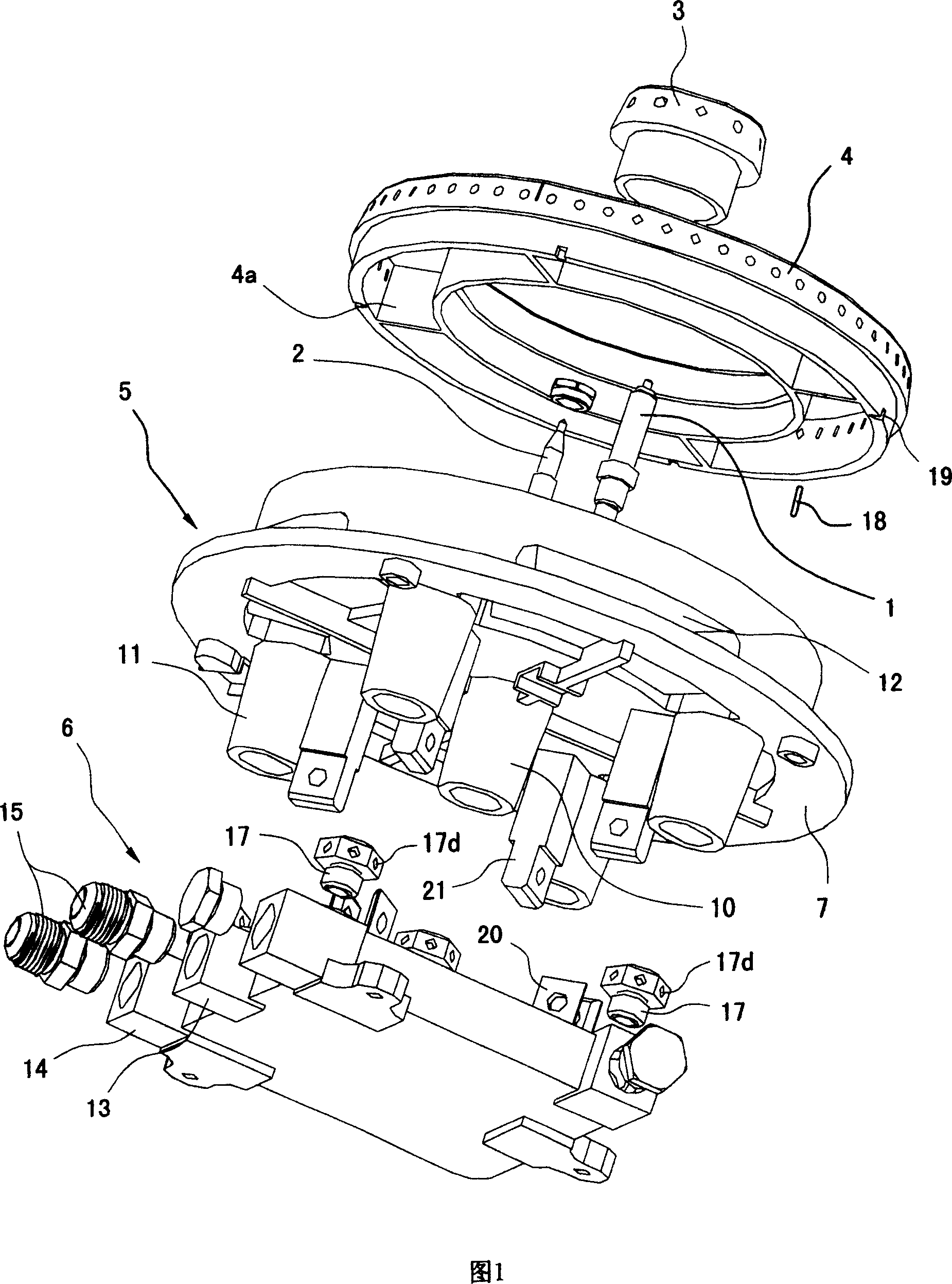

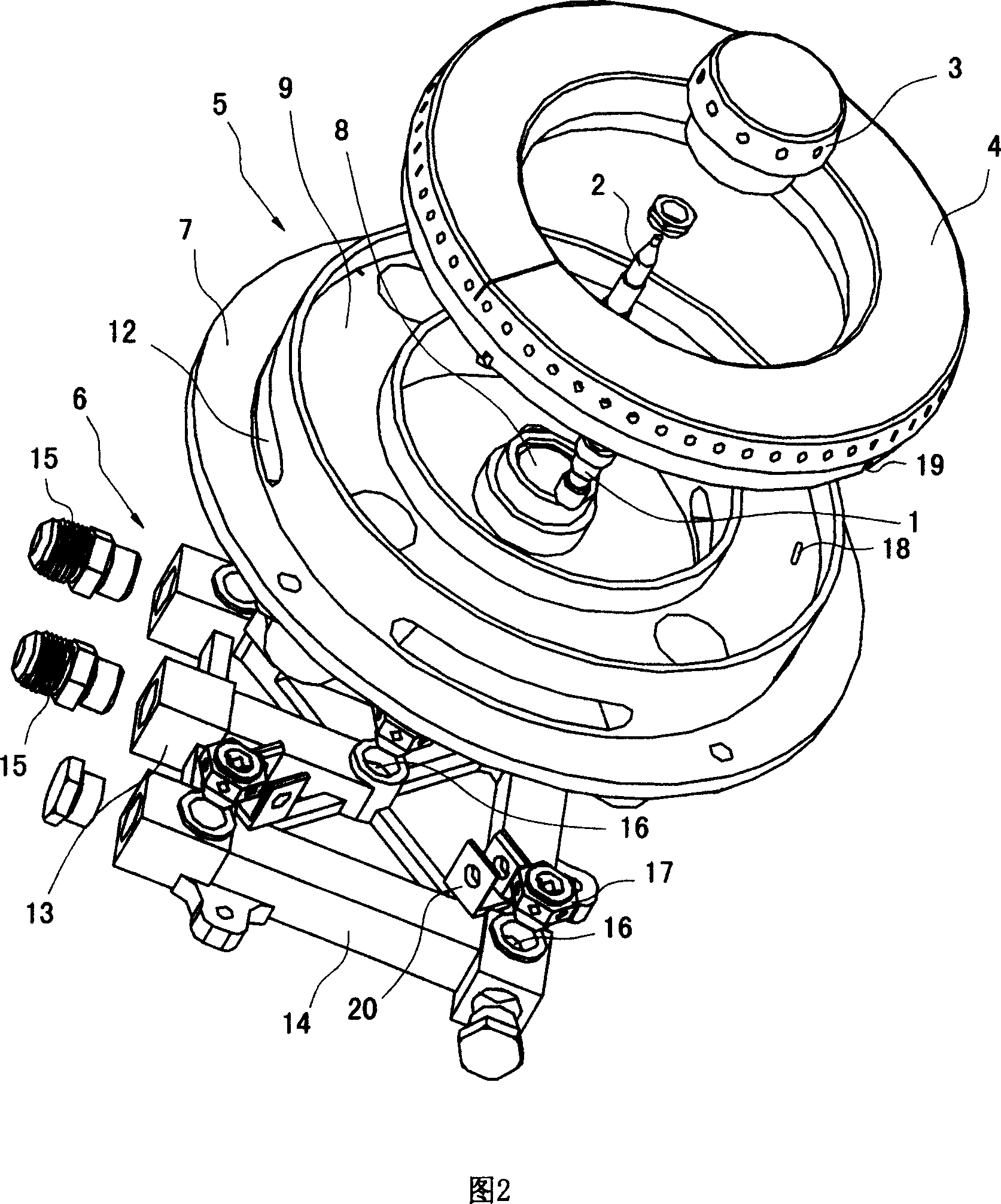

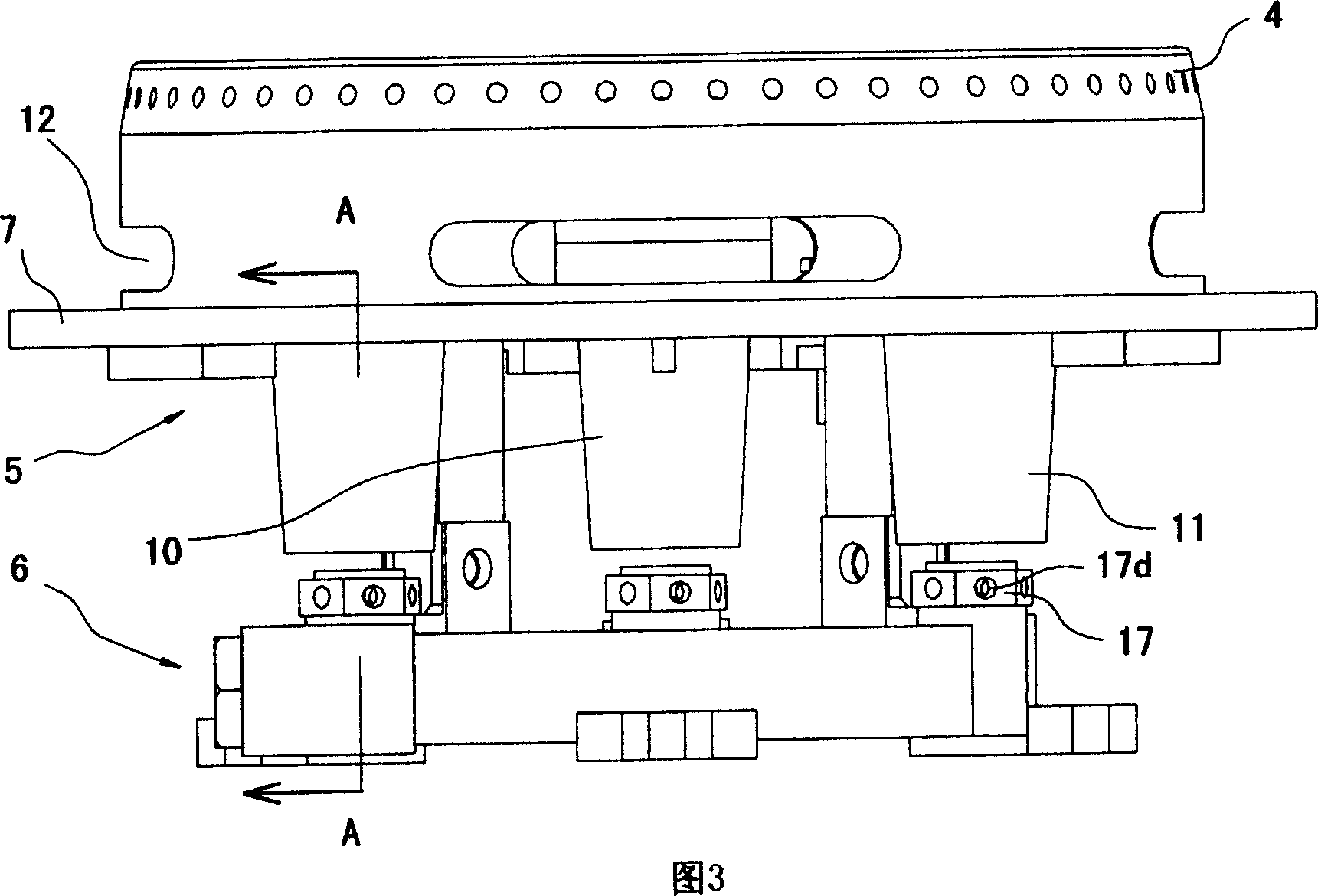

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0020] As shown in Fig. 1 to Fig. 5, it is a preferred embodiment of the present invention. As shown in Figures 1 to 5, the multi-cavity integrated burner in this embodiment has a ignition needle 1, a thermocouple 2, an inner ring flamethrower 3, an outer ring flamethrower 4, an integrally formed gas mixing chamber and an ejector Tube assembly 5 and base assembly 6. The integrally formed gas mixing chamber and injection tube assembly 5 includes a bottom plate 7, an inner ring gas mixing chamber 8 and an outer ring gas mixing chamber 9 are integrally formed above the bottom plate 7, and a vertical inner ring is formed integrally below the bottom plate 7. Injection tube 10 and four vertical external injection tubes 11. Among them, the inner injection pipe 10 is located directly below the inner ring gas mixing chamber 3, while the four outer in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com