Vehicle body comprising elastically mounted bonnet

An automotive body, elastic support technology, used in pinned hinges, hinges, vehicle parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

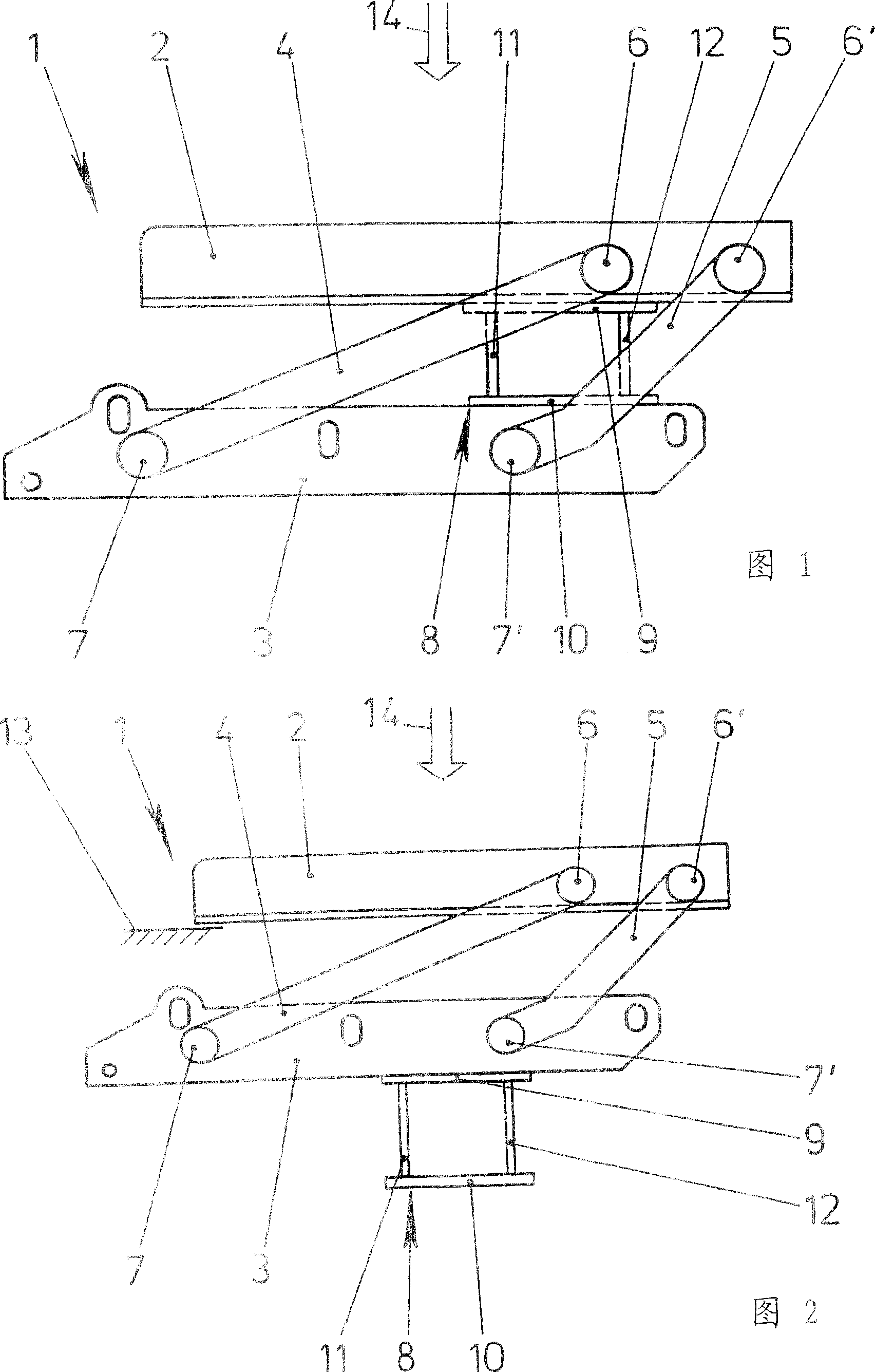

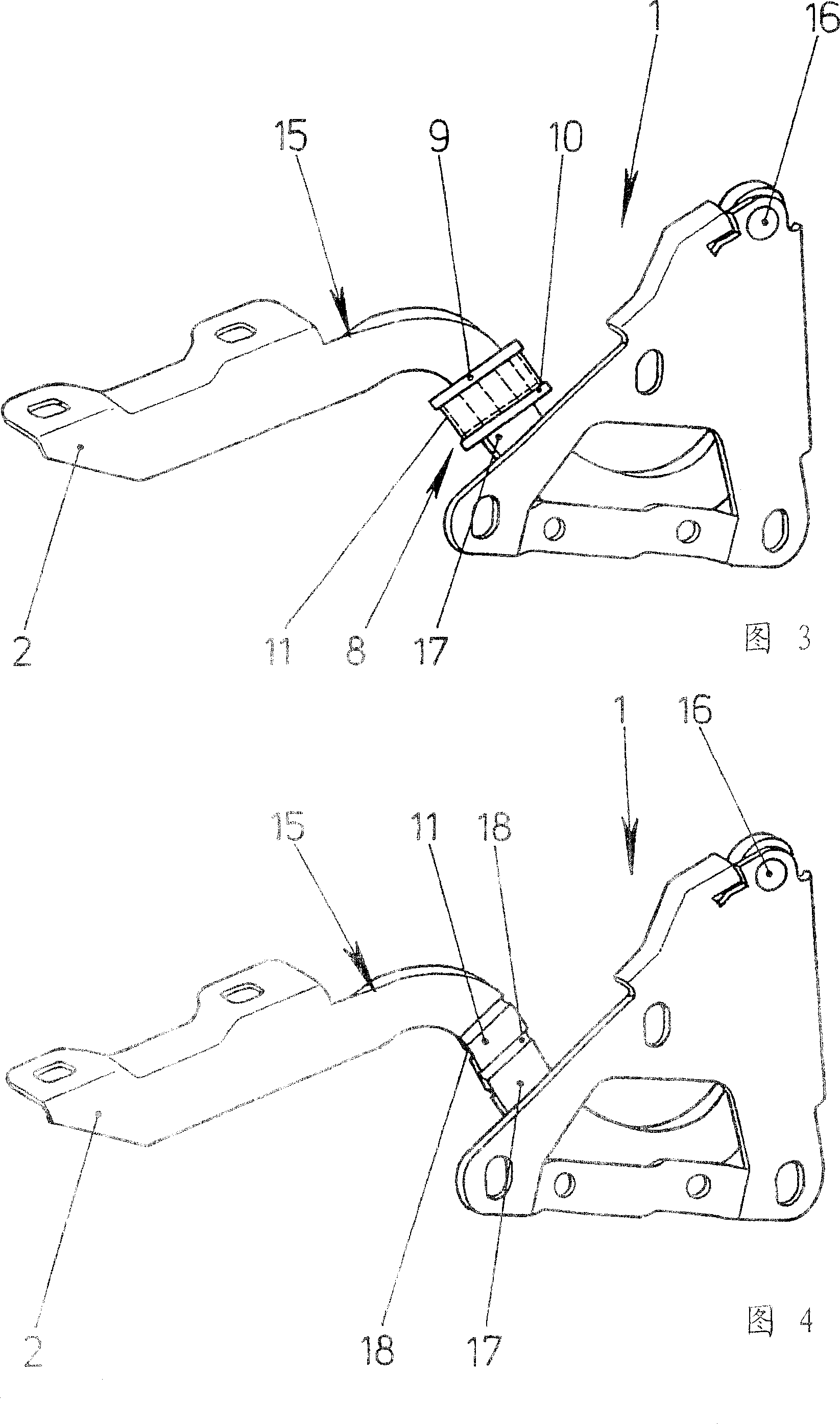

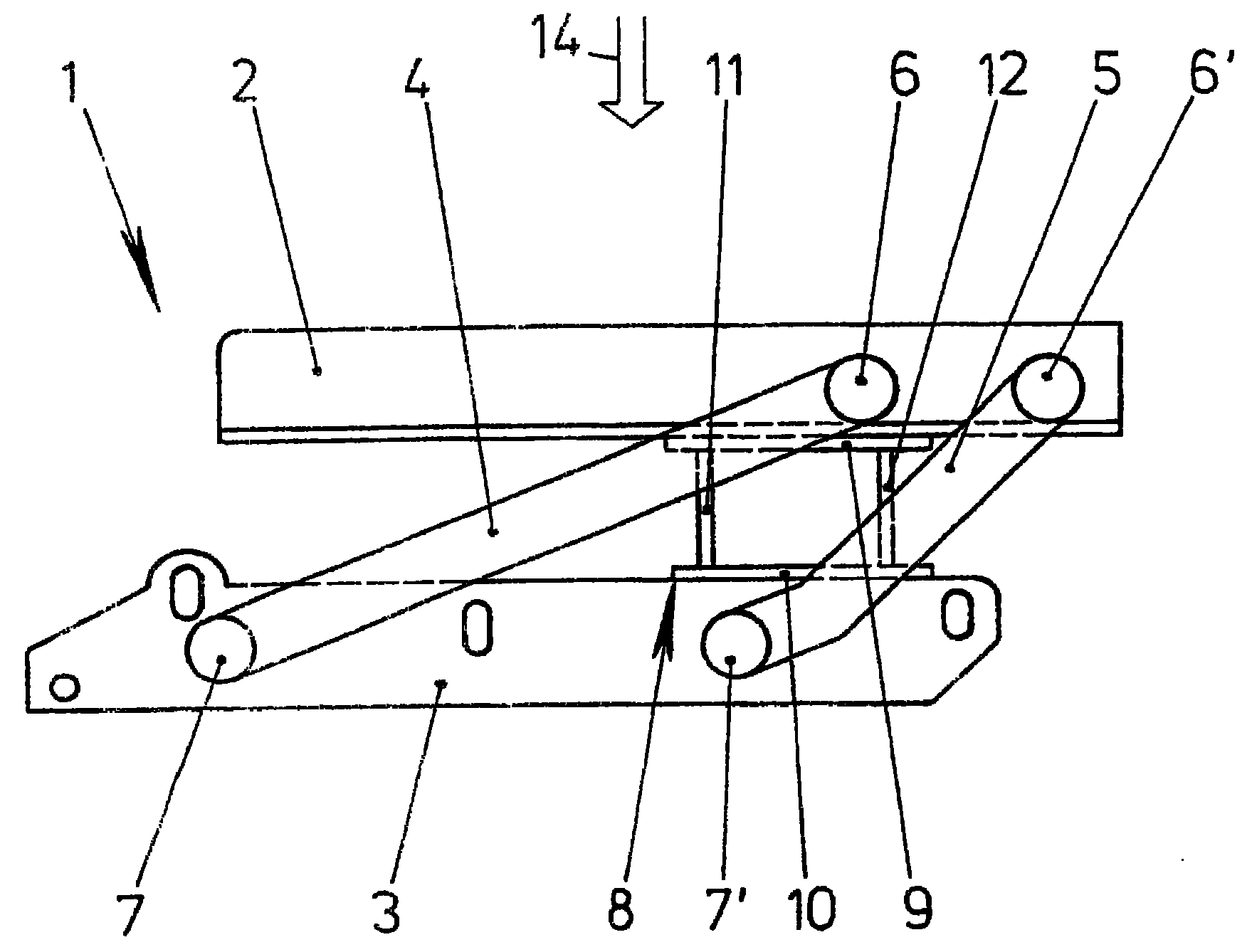

[0020] The two FIGS. 1 and 2 show a hinge structure 1 for a (not shown in detail here) front panel. The hinge structure 1 is composed of an upper tie rod 2 welded or bolted to the front cover and a lower tie rod 3 bolted to the vehicle body. Two folding levers 4 , 5 , which are rotatably supported on the struts 2 , 3 respectively at joints 6 , 6 ′, 7 , 7 ′, extend between the two struts 2 , 3 . In order to move the front flap upwards or forwards when it is turned up, so as to prevent the rear edge of the front flap from colliding with a frame surrounding the front flap, one folding lever 4 is longer than the other folding lever 5 , and the two joints 6, 6' on the upper stay rod 2 are arranged closer to each other than the two joints 7, 7' on the lower stay rod 3. In this way, the swivel axis of the front flap is deflected forward when the front flap is opened.

[0021] According to the structure shown in FIG. 1 , a crash box 8 is located between the two struts 2 , 3 and near...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com