Reciprocating compressor

A compressor and reciprocating technology, applied in the direction of liquid variable displacement machinery, mechanical equipment, engine components, etc., can solve problems such as valve damage, and achieve the effect of reducing operating stress, reducing pressure, and reducing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

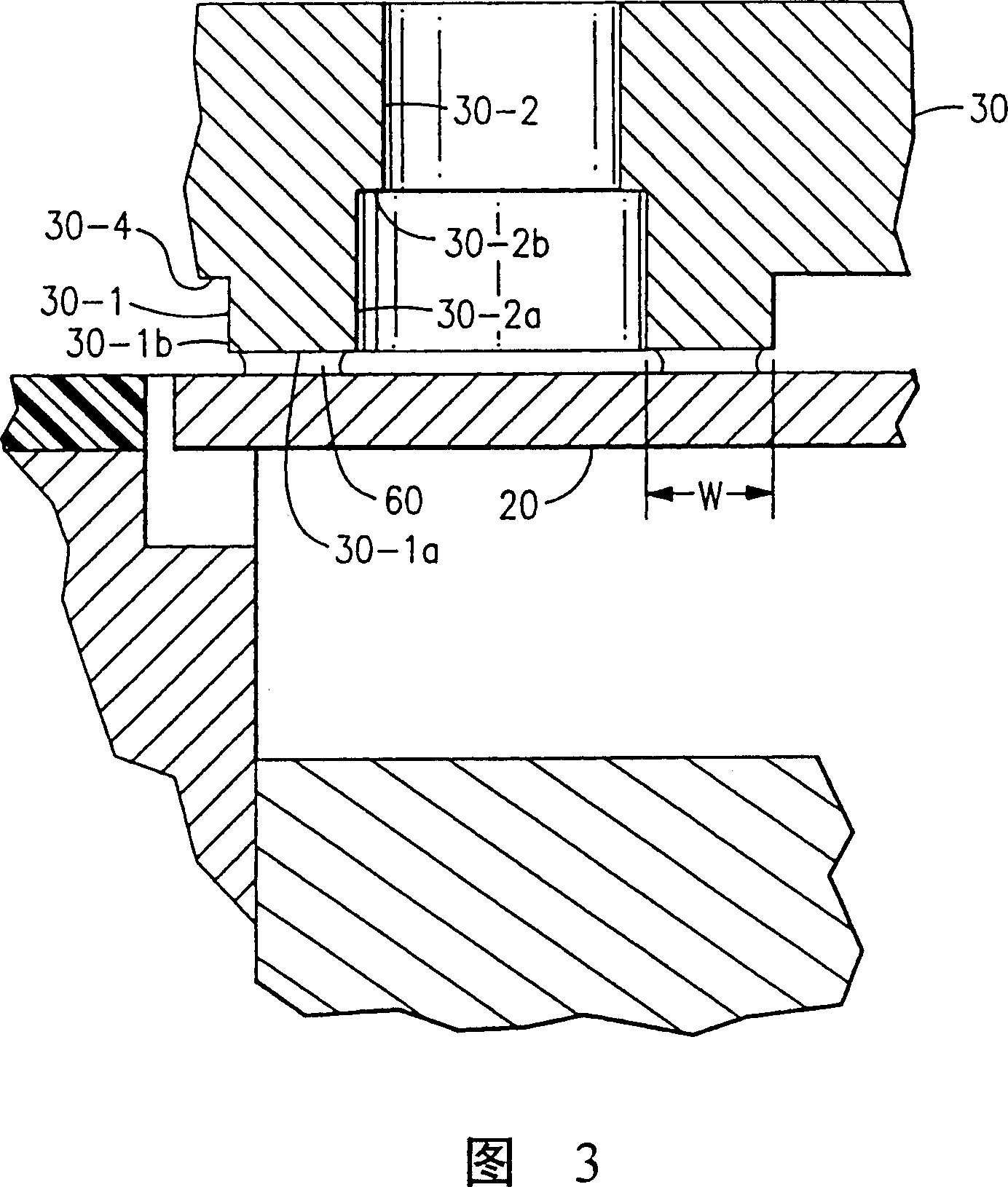

[0023] In Figs. 1 and 2, reference numeral 10 generally denotes a reciprocating compressor. As with conventional compressors, compressor 10 has a suction valve 20, shown as a reed valve, and a discharge valve 50, and a piston 42 located in a bore or cylinder 40-3. The discharge valve 50 has a valve pad 51 which limits the movement of the valve 50 and is generally designed to dissipate the opening force applied to the valve 50 over its entire opening movement through the discharge passage 30-5. In the case of the suction valve 20, its valve tip 20-1 engages with a flange 40-1 in a groove 40-2 in the crankcase 40 which acts as a valve stop. Flange 40-1 engages after 0.1 inches of opening movement to reduce clearance volume and further opening movement by flexing of valve 20, as shown in phantom in FIG. Specifically, valve 20 initially moves as a cantilever until valve tip 20-1 engages flange 40-1 and then bends in the form of a beam supported at both ends. As shown in phantom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com