Methanism for preventing pipe line from wearing-out and processing apparatus

A process equipment and pipeline technology, applied in the field of pipeline wear prevention mechanism and process equipment using the pipeline wear prevention mechanism, to achieve the best product quality, avoid machine failure, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The specific structure, features and functions of the anti-pipeline abrasion mechanism and the process equipment using the anti-pipeline abrasion mechanism according to the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

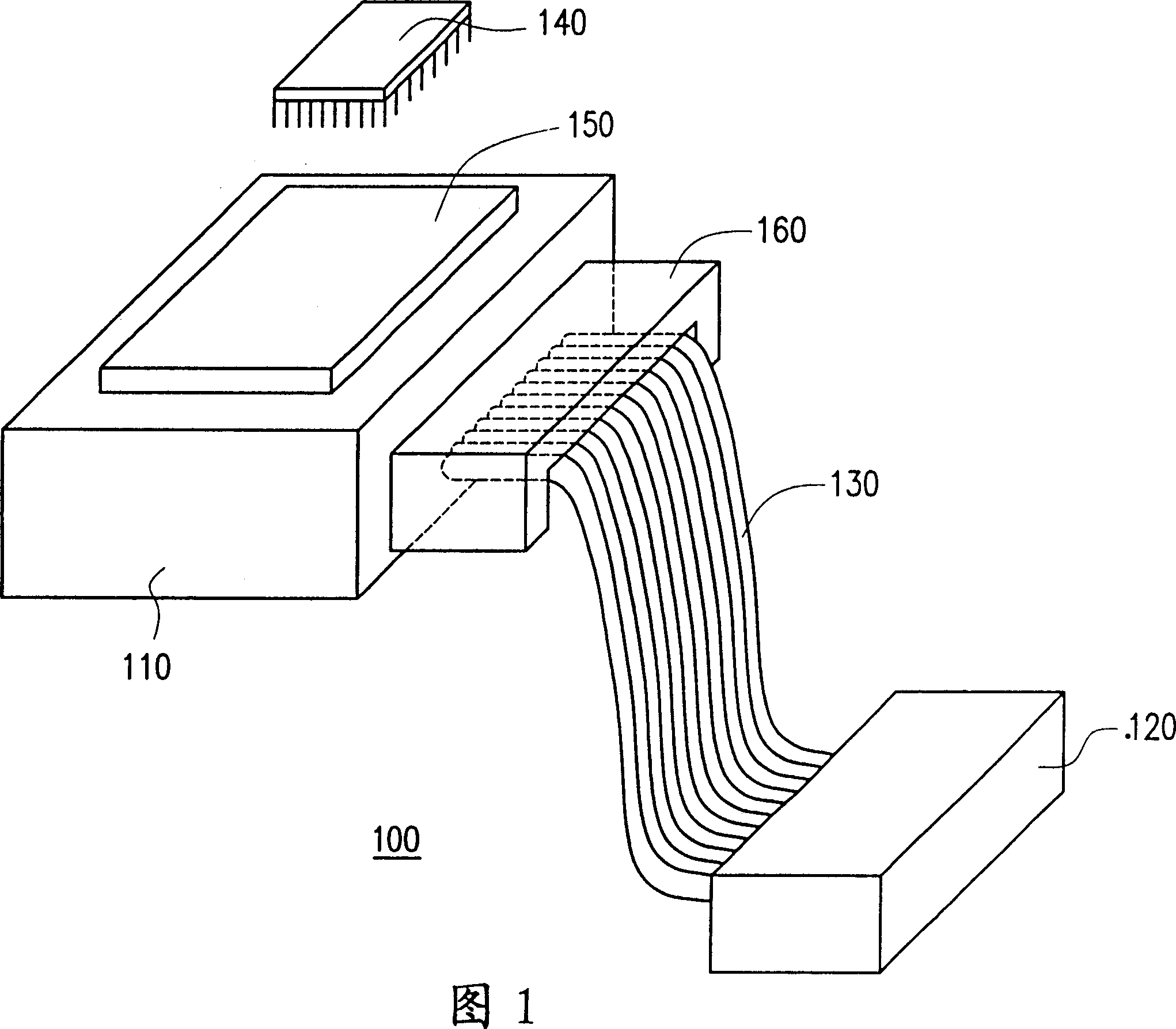

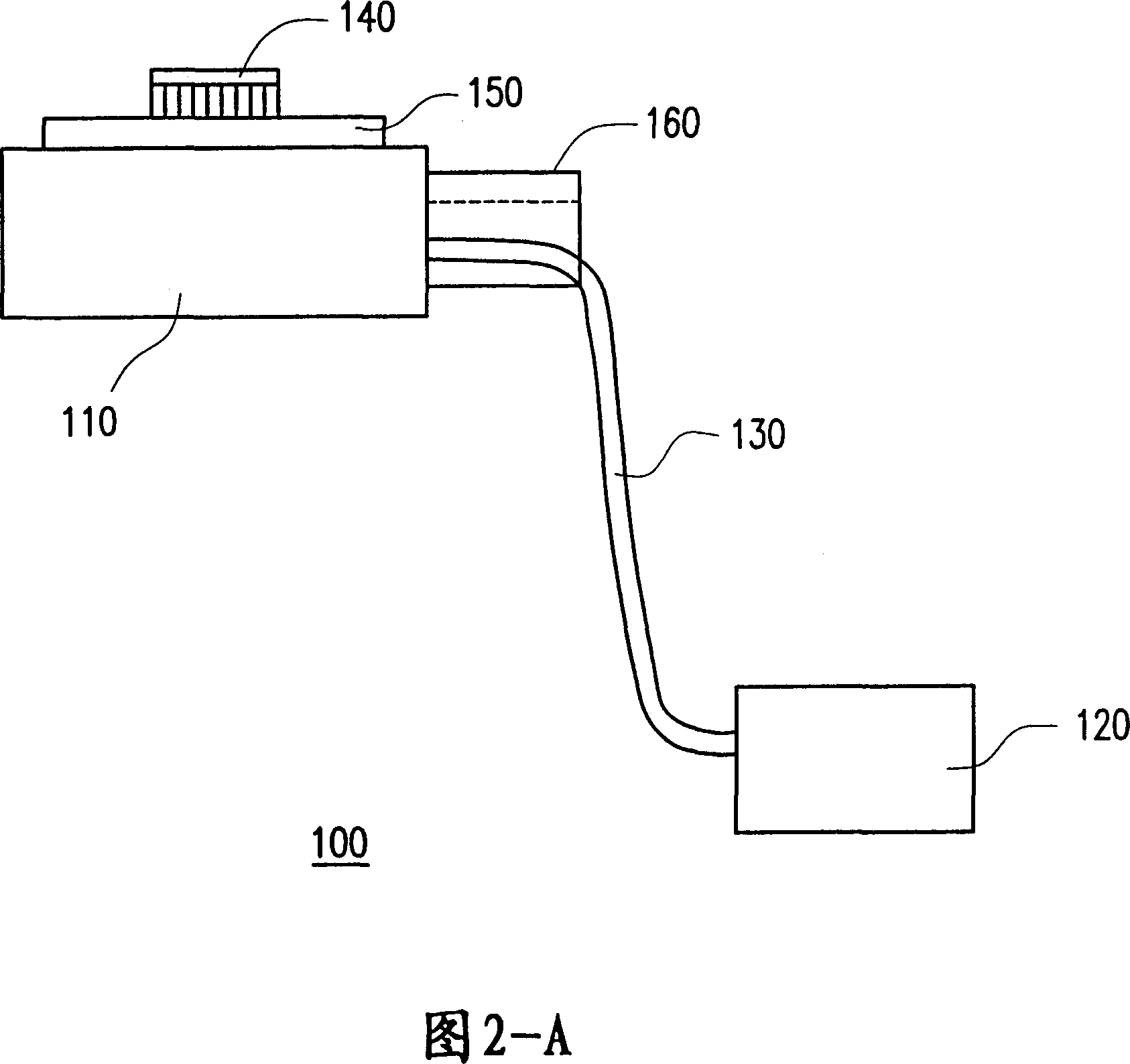

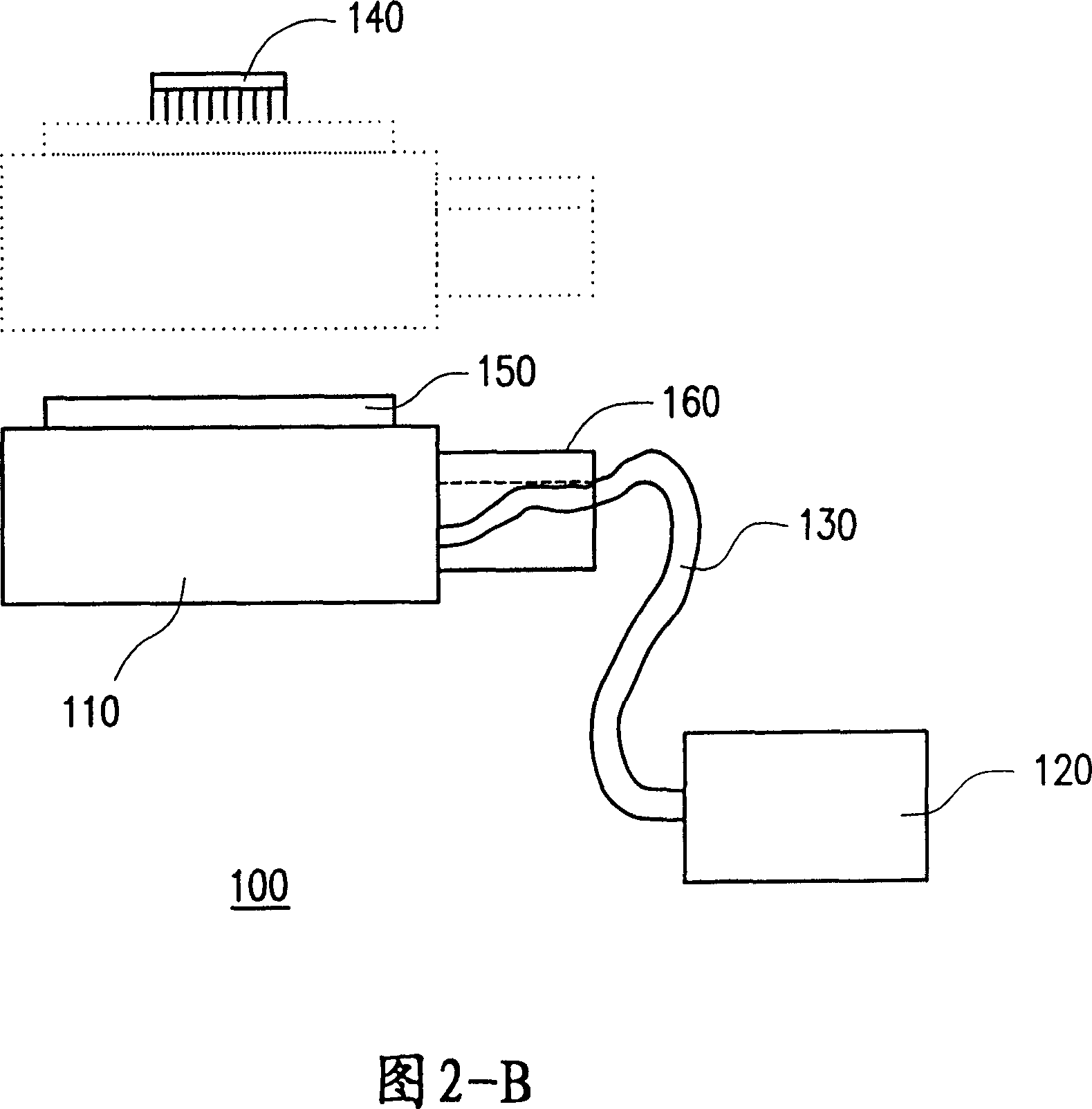

[0054] Please refer to FIG. 3 , which is a schematic perspective view of the first process equipment in a preferred embodiment of the present invention. The process equipment 200 is, for example, applied to an electrical test of a liquid crystal display panel, and is composed of, for example, a stage 210 , an air extraction device 220 , a pipeline 230 , a cover plate 240 and a pipeline wear prevention mechanism 250 . Wherein, the stage 210 can move horizontally and vertically in space, and the pipeline 230 is connected between the stage 210 and the air extraction device 220, and the air extraction device 220 can pump the stage 210 through the pipeline 230 gas action. In this w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com