Cylinder stripper

A technology of rollers and guide rollers, used in cleaning devices, transportation and packaging, conveyor objects, etc., can solve the problems of different material removal, wear, uneven scraping ability, etc., and achieve the effect of close contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

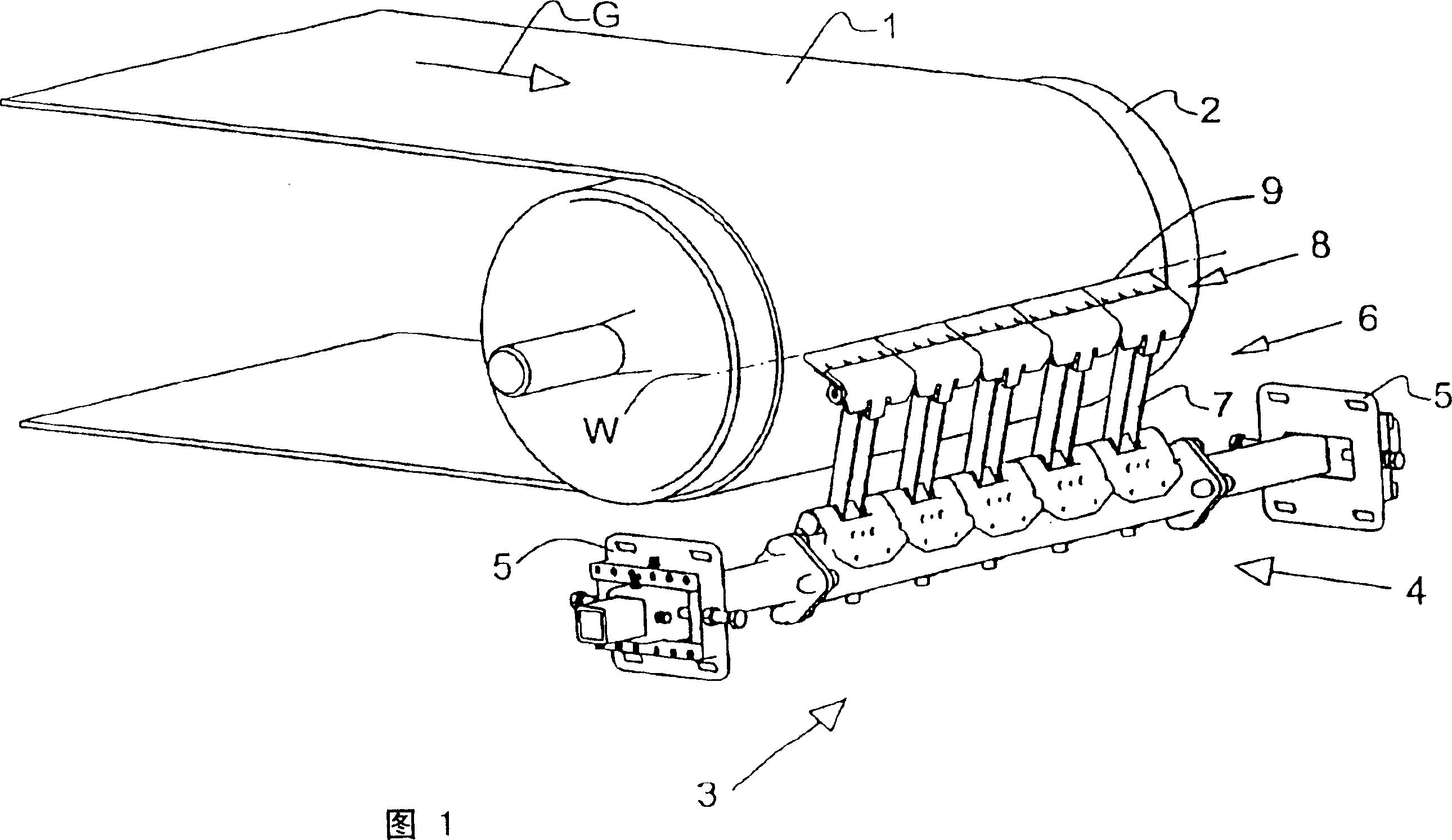

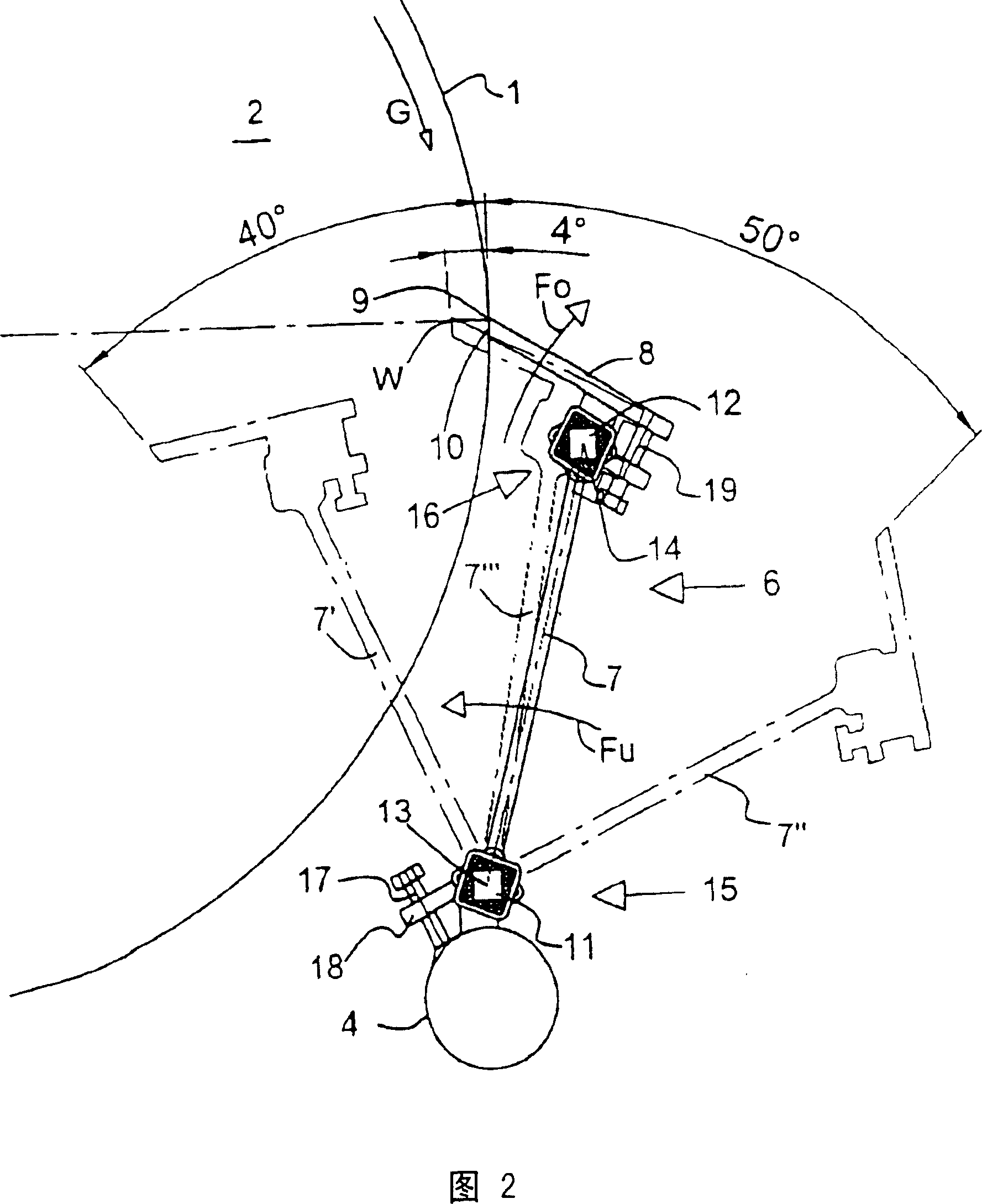

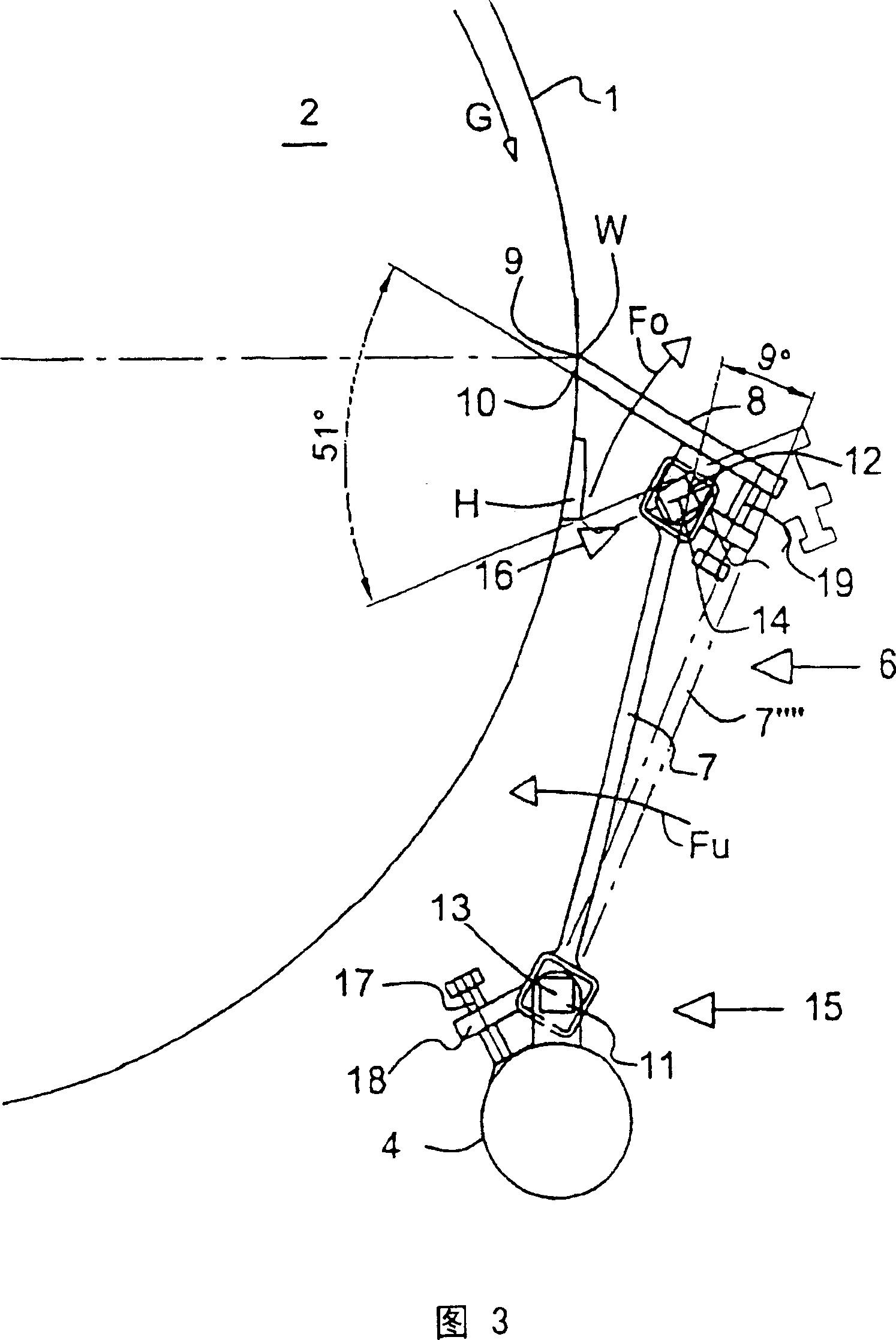

[0064] In the figure, a conveyor belt 1 is arranged around a roller 2 (drive roller and / or guide roller), which rotates around the roller 2 in the direction of conveyor belt travel indicated by arrow G, in this case at a wrap angle of approximately 90°. The drum 2 is usually mounted rotatably in a frame (not shown) of a belt conveyor.

[0065]At the head of the conveyor belt 1 is provided a device 3 as a pre-scraper for scraping dirt off the conveyor belt 1 . The system frame 4 on which five scraping elements 6 are arranged next to each other in a row is moved in the frame of a belt conveyor (not shown) at its two ends by means of side frames 5 . Each scraping member 6 is supported on the system support 4 with a sheet-like support 7 and above (“above” or “horizontal” or similar expressions, here and below refer in principle to the use position of the scraping member 6) with a scraper Sheet 8, it with scraping edge 9 on the so-called 3 o'clock position along a dotted line of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com