Method for controlling fuel metering in multiple injection operating mode

A technology of running and fuel quantity, applied in the direction of fuel injection control, electrical control, engine control, etc., can solve the problems of inaccurate fuel metering engine and short valve opening time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

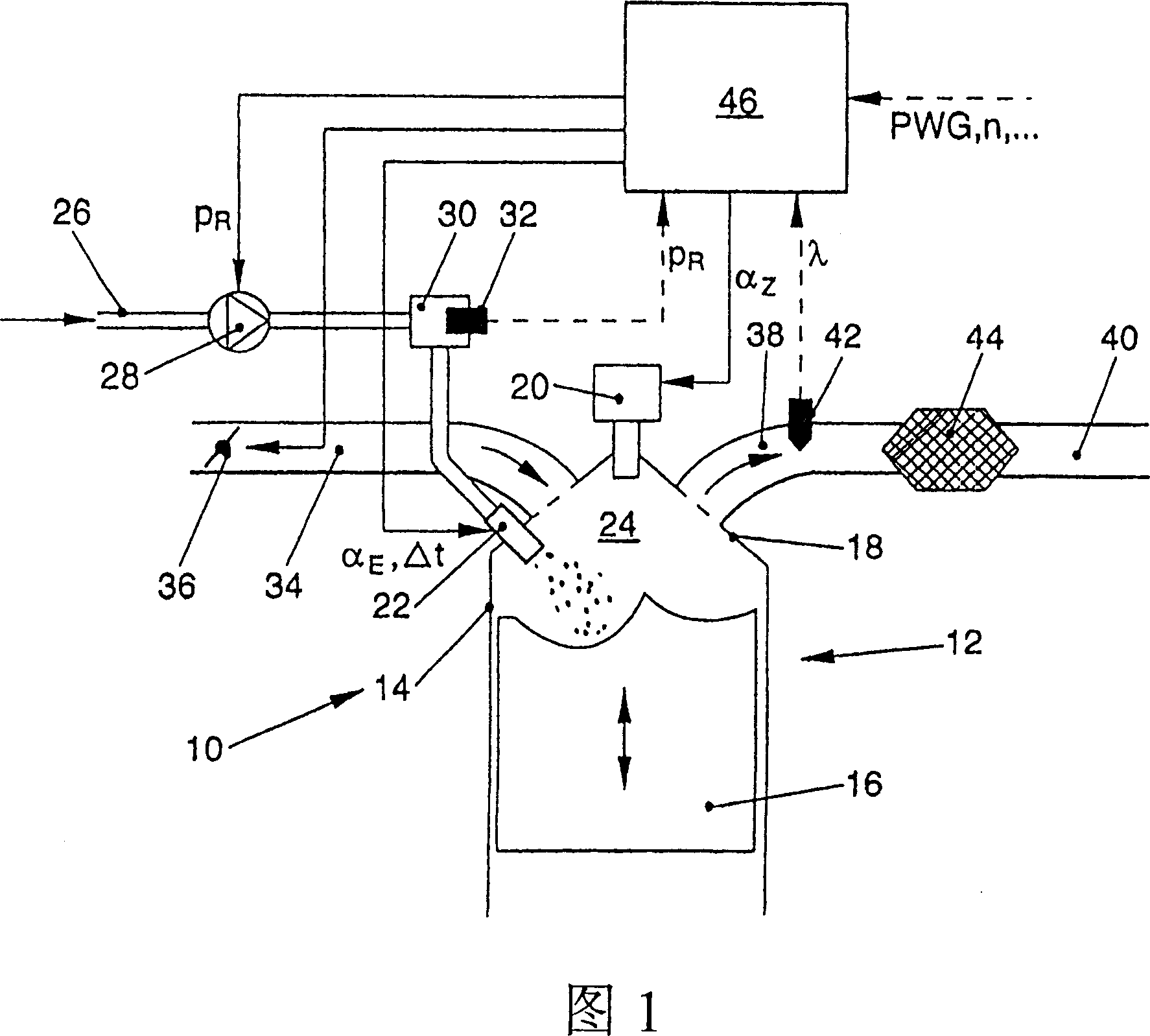

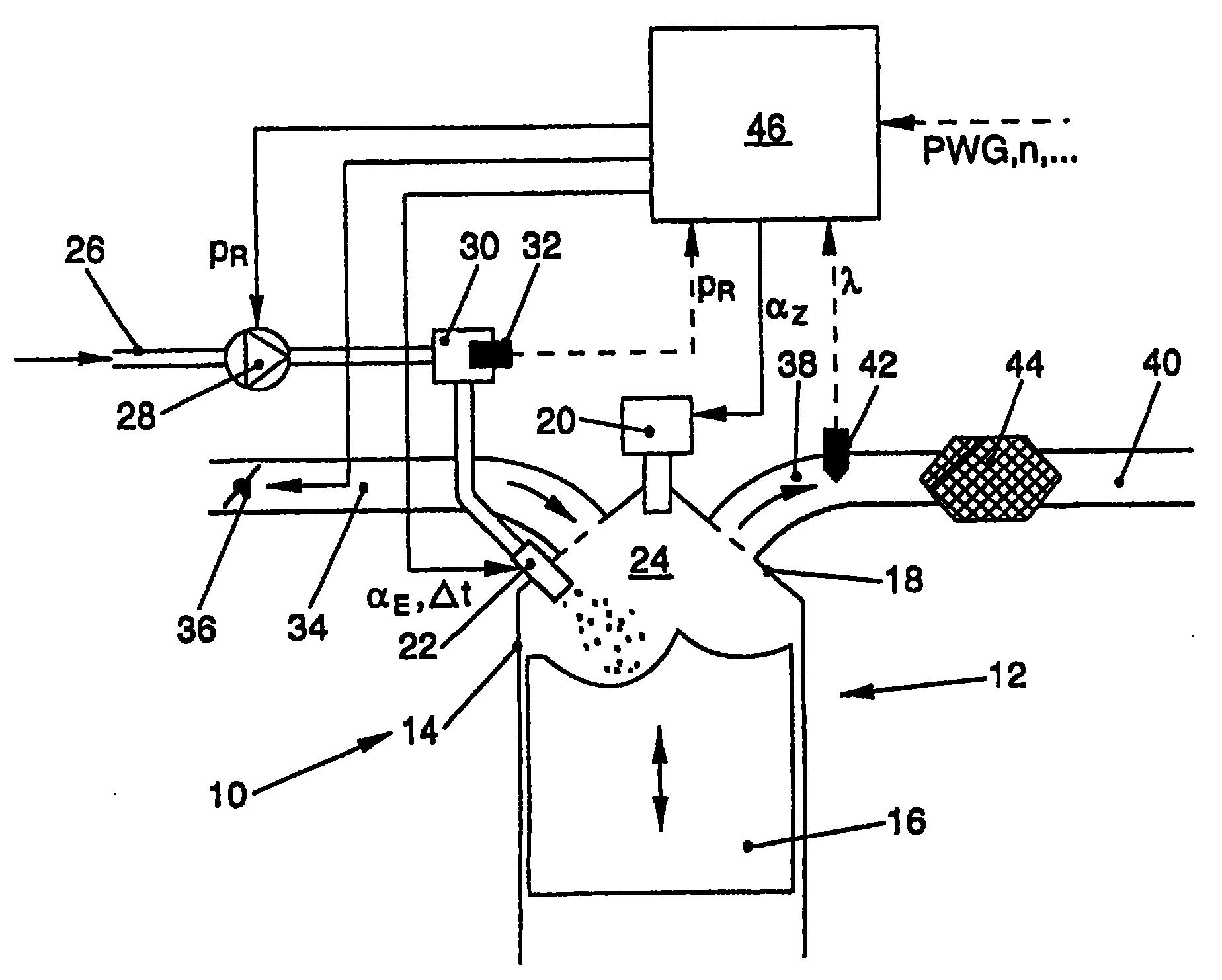

[0020] FIG. 1 shows only the cylinders 12 of a four-stroke internal combustion engine 10 with spark ignition and relatively low driving capability as an example. An axially movable piston 16 is accommodated in a cylinder housing 14 of the cylinder 12 . In the cylinder head 18 of the cylinder housing 14, the spark plug 20 with the ignition coil is located at the upper center position, and the high-pressure injection valve 22 is at the side position, and the fuel can be directly injected into the cylinder 12 by using this high-pressure valve. In the combustion chamber 24. Fuel can be supplied to injector 22 via fuel line 26 . Fuel can be pumped from a fuel tank, also not shown, by a fuel pump, not shown, and brought to a slight pre-pressure. The high pressure pump 28 can be used to generate fuel pressure which is between 40 and 120 bar during normal driving. The fuel pressure is set according to the operating point of the internal combustion engine 10 . In addition, the high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com