Process for preparing a polymer dispersion

A polymer, dispersion technology used in retention aid additions, paper, textiles and papermaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

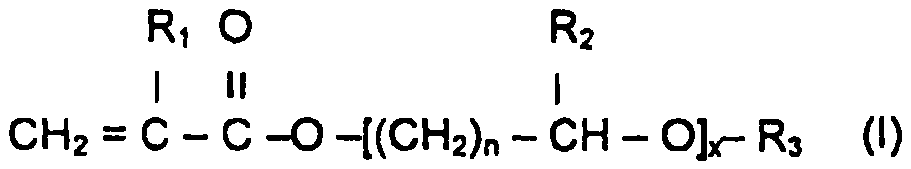

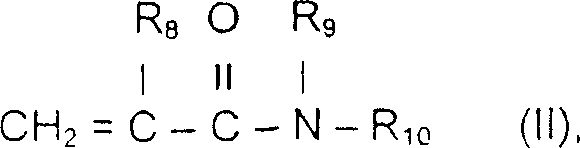

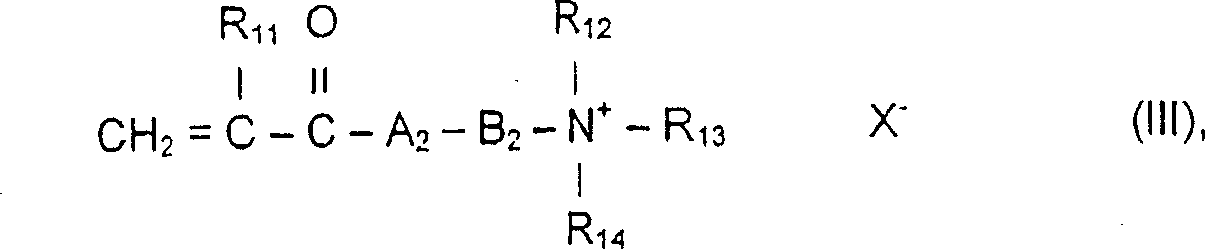

Method used

Image

Examples

Embodiment 1-5

[0046] By polymerizing diallyl-dimethyl ammonium chloride (DADMAC), acryloyloxyethyl-trimethyl ammonium chloride (ADAM MC Q) and poly(ethylene glycol) methyl ether acrylate (M-PEG acrylates) to synthesize dispersant polymers. The result is an aqueous solution of dispersant with a dry content of dispersant polymer of about 40% by weight.

[0047] Table 1. Dispersant Polymers

[0048] Example

[0049] *Molecular weight of dispersant polymer determined by GPC

Embodiment 6-8

[0051] Also by polymerizing diallyl-dimethylammonium chloride (DADMAC), acryloyloxyethyl-trimethylammonium chloride (ADAM MC Q) and monofunctional vinyl-terminated ethers and polyethers of different mono Body (m 4 ) to synthesize a dispersant polymer. The monomer composition in all examples was 48.75 mol% DADMAC, 48.75 mol% ADAM MC Q and 2.5 mol% amphiphilic monomer. Here again the result of the polymerization is an aqueous solution of dispersant with a dry content of dispersant polymer of about 40% by weight.

[0052] Table 2. Dispersant Polymers

[0053] Example

[0054] *Molecular weight of dispersant polymer determined by GPC

Embodiment 9

[0055] Embodiment 9 (comparison)

[0056] Also synthesized without any monomer m 4 the dispersant.

[0057] Table 3. Comparative Dispersants

[0058] Example

[0059] *Molecular weight of dispersant polymer determined by GPC

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com