Longitudinal of vacuum circuit breaker transmission

A technology of vacuum circuit breaker and transmission mechanism, applied in the direction of high-voltage air circuit breaker, circuit, electrical components, etc., can solve the problems of reduced mechanism reliability, large contact bounce, large closing power of spring mechanism, etc., and achieve breaking performance. Reliable, small closing bounce, small closing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

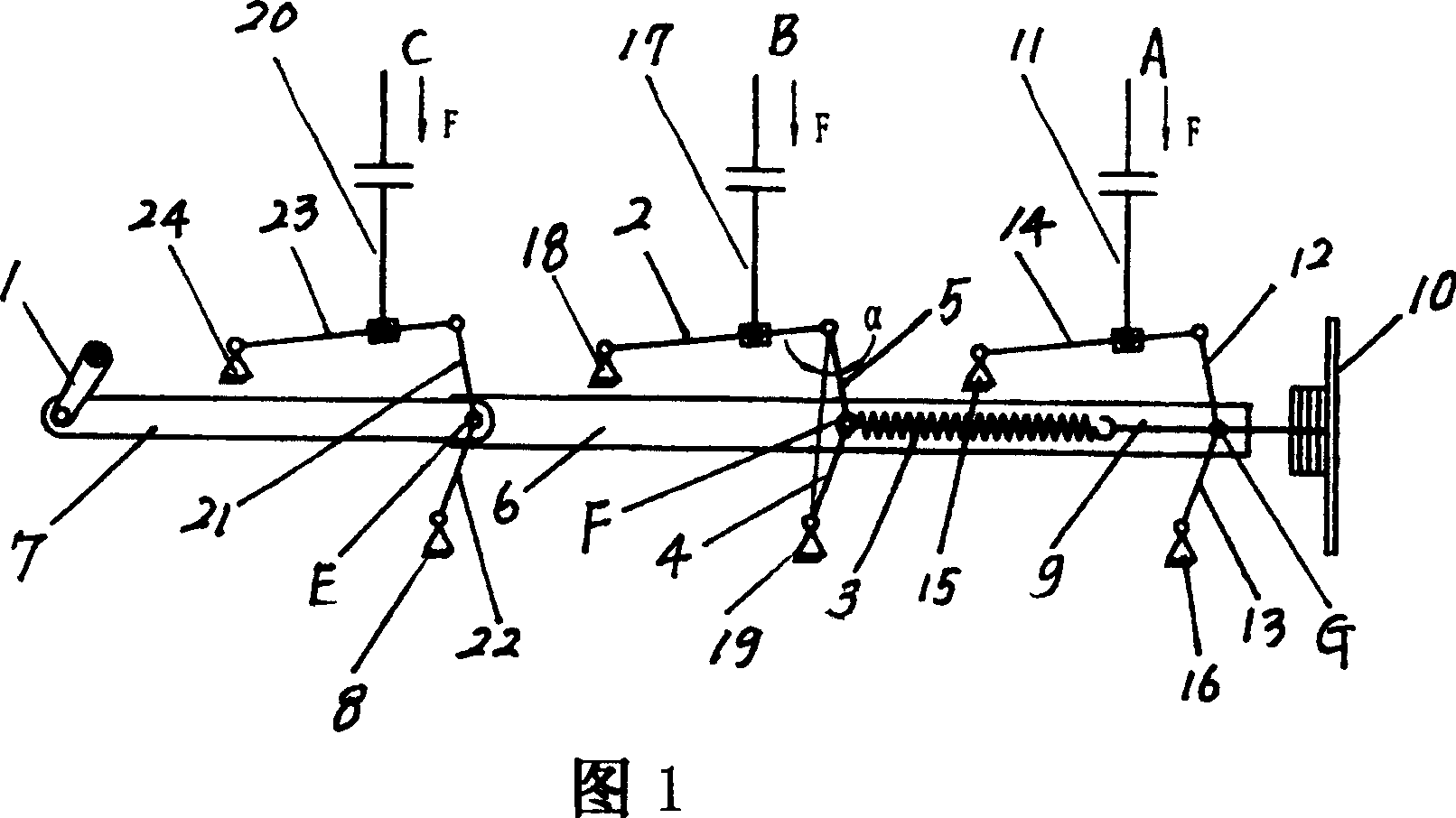

[0020] The transmission mechanism of the longitudinal vacuum circuit breaker includes the front connecting rod 7, the rear connecting rod 6, the opening spring 3, the pull rod mechanism of A phase, the pull rod mechanism of B phase and the pull rod mechanism of C phase.

[0021] The front end of front connecting rod 7 is hinged a mechanism shaft 1, and the rear end of front connecting rod 7 is connected with the front end of rear connecting rod 6 by axis E. A shaft F and a shaft G are respectively fixed at set positions on the rear link 6 .

[0022] The A-phase pull rod mechanism includes a pull rod 11 , an upper link 12 , a lower link 13 and an arc extinguishing chamber crank arm 14 . The lower end of the pull rod 11 is hinged with the arc extinguishing chamber crank arm 14 , one end of the arc extinguishing chamber crank 14 is hinged with the fixed fulcrum 15 , and the other end is hinged with the upper end of the upper link 12 . The lower end of the upper connecting rod 12...

Embodiment 2

[0027] The second embodiment is basically the same as the first embodiment, except that the angle between the connection line between the upper link 12 and the lower link 13 and the upper link 12 after closing is 3°; after closing, the upper link 5 The angle between the line connecting the lower link 4 and the upper link 5 is 3°; the angle between the line connecting the upper link 21 and the lower link 22 and the upper link 21 after closing is 3° .

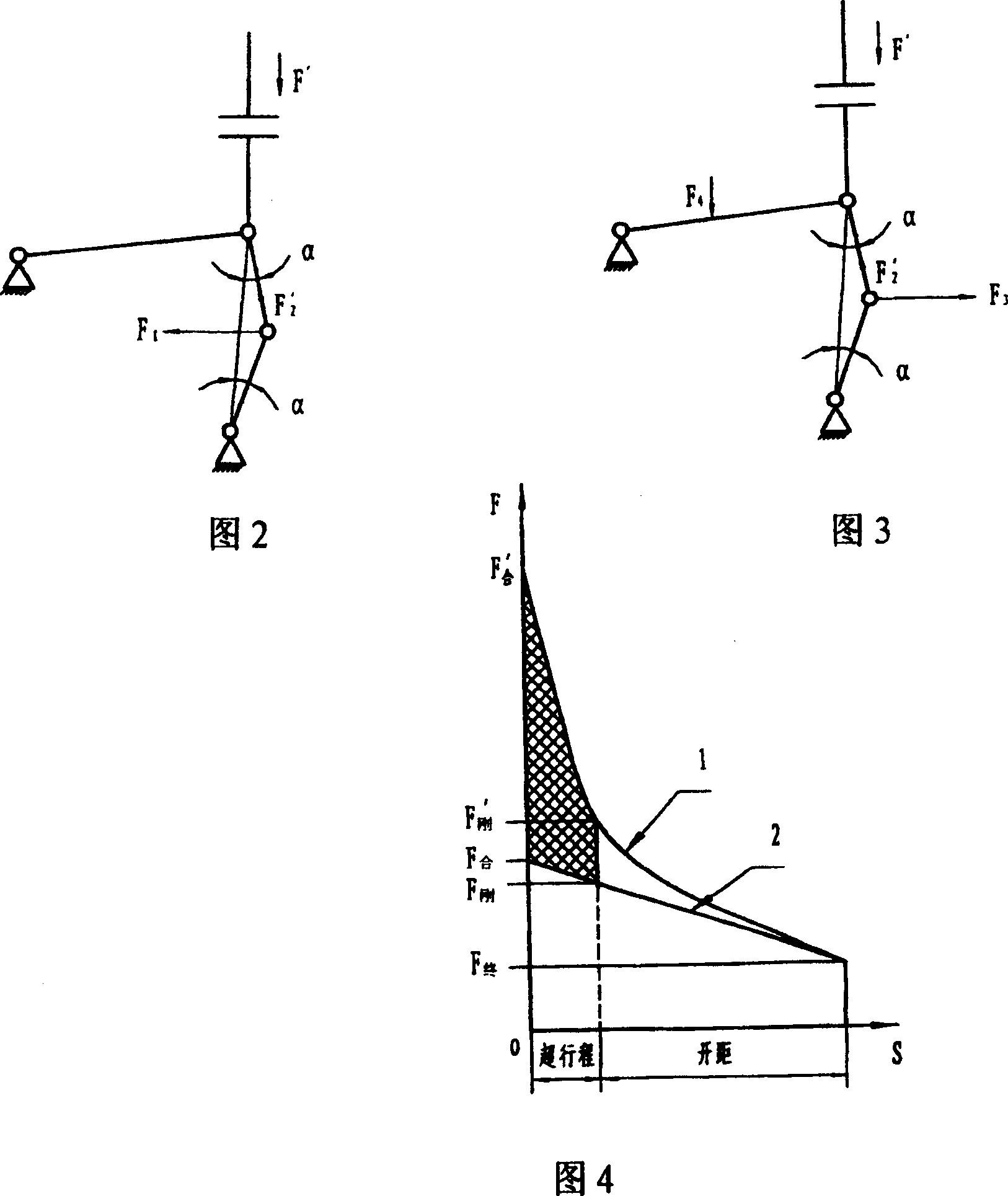

[0028] The characteristics of closing and opening force are analyzed as follows:

[0029] A. Characteristic analysis of closing force:

[0030] See Figure 2. When connecting rod 4 is equal to connecting rod 5, it can be obtained from calculation:

[0031] F1=2SinαF2'

[0032] After the structure is closed, the α angle is controlled at 3°

[0033] F1=2Sin3°F2'

[0034] =0.1F2'

[0035] When the α angle is controlled at 10°

[0036] F1=2Sin10°F2'

[0037] =0.35F2'

[0038] It can be seen from the relationship that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com