Process for electrolyzing preparing electrolyte of full vanadium ion flow battery

A technology of flow battery and vanadium ion, applied in the field of battery manufacturing, can solve the problems of complex assembly and chemical formation process of vanadium battery, shortened life of vanadium battery, affecting production efficiency, etc. The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] V 2 o 3 : TV63%

[0017] V 2 o 5 : Analytical pure

[0018] h 2 SO 4 : Analytical pure, d=1.84

[0019] Na 2 SO 4 : Analytical pure

[0020] Emulsifier OP

[0021] Production of electrolytic cell: plexiglass plate is used to make the frame pole, the conductive diaphragm is activated Nafion proton exchange membrane, the cathode cell is 50×50×20mm, and the anode cell is 50×50×20mm.

[0022] Electrode production: 40×40×1,5mm lead plate.

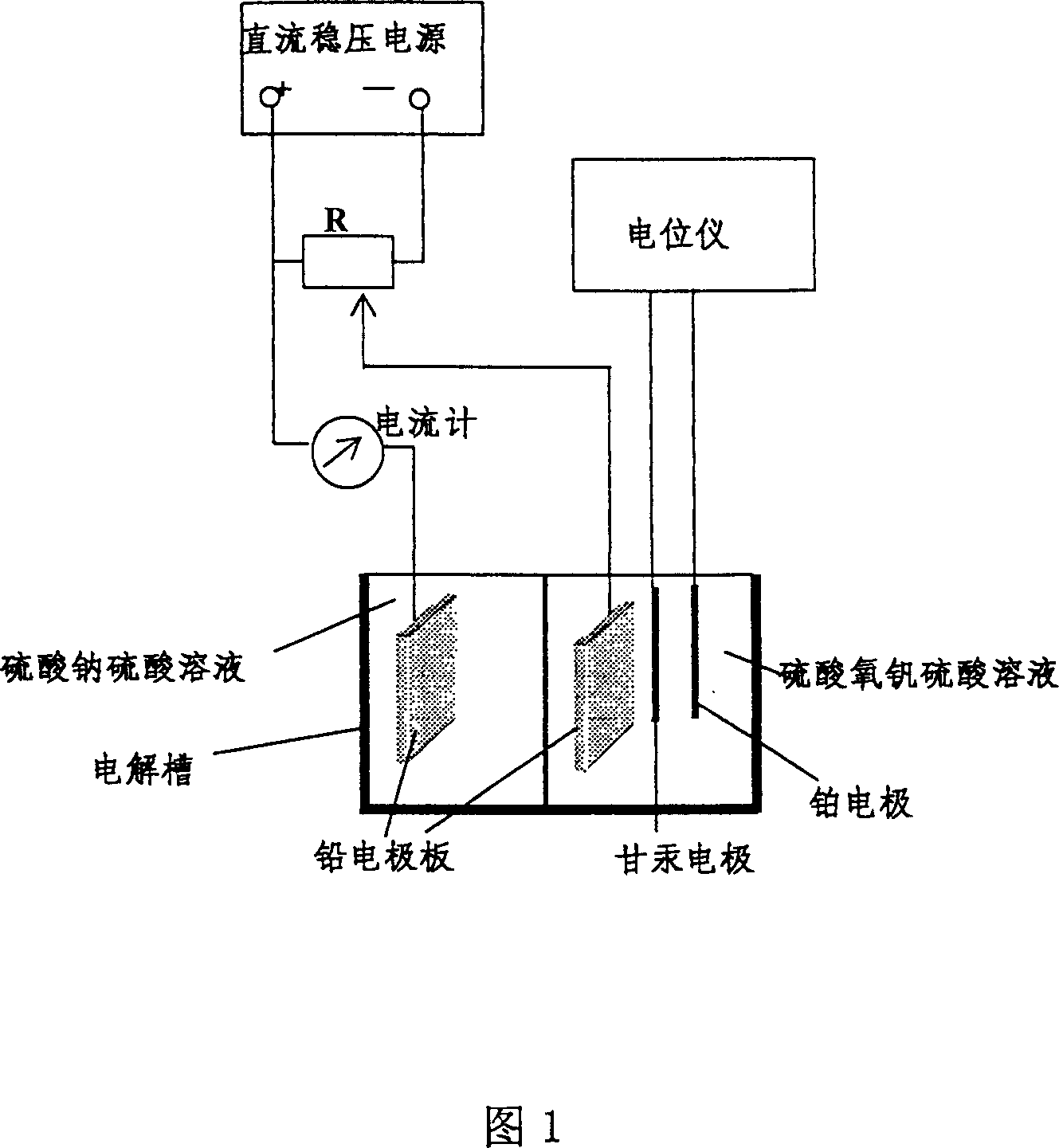

[0023] Equipment and connection: DC regulated power supply, variable resistor, see the attached diagram for the connection diagram.

[0024] Vanadium battery model making: plexiglass plate as frame plate, Nafion proton exchange membrane as conductive diaphragm, self-made carbon electrode. The size of the model is: 50×50×10mm.

[0025] Weigh 50 grams of V according to the proportion 2 o 3 , 30g V 2 o 5 , 300 grams of concentrated sulfuric acid, appropriate amount of distilled water and other raw materials, after the react...

Embodiment 2

[0027] V 2 o 3 : TV73%

[0028] V 2 o 5 : Analytical pure

[0029] h 2 SO 4 : Analytical pure, d=1.84

[0030] Na 2 SO 4 : Analytical pure

[0031] Emulsifier OP

[0032] Production of electrolytic cell: frame plate made of plexiglass plate, Nafion proton exchange membrane after activation treatment is used as conductive diaphragm, cathode pool 50×50×20mm, anode pool 50×50×20mm.

[0033] Electrode production: 40×40×1.5mm lead plate.

[0034] Equipment and connection: DC regulated power supply, variable resistor, see the attached diagram for the connection diagram.

[0035] Vanadium battery model making: plexiglass plate as frame plate, Nafion proton exchange membrane as conductive diaphragm, self-made carbon electrode. The size of the model is: 50×50×10mm.

[0036] Weigh 130 grams of V according to the ratio 2 o 3 , 70g V 2 o 5 , 450 grams of concentrated sulfuric acid, appropriate amount of distilled water and other raw materials, after the reaction, add 30 ...

Embodiment 3

[0038] V 2 o 3 : TV63%

[0039] V 2 o 5 : Analytical pure

[0040] h 2 SO 4 : Analytical pure, d=1.84

[0041] Na 2 SO4 : Analytical pure

[0042] Emulsifier OP

[0043] Production of electrolytic cell: frame plate made of plexiglass plate, Nafion proton exchange membrane after activation treatment is used as conductive diaphragm, cathode cell 200×200×40mm, anode cell 2000×200×40mm.

[0044] Electrode production: 100×100×1.5mm lead plate.

[0045] Equipment and connection: DC regulated power supply, variable resistor, see the attached diagram for the connection diagram.

[0046] Vanadium battery model making: plexiglass plate as frame plate, Nafion proton exchange membrane as conductive diaphragm, self-made carbon electrode. The size of the model is: 50×50×10mm.

[0047] Weigh 100 grams of V according to the proportion 2 o 3 , 55 g V 2 o 5 , 400 grams of concentrated sulfuric acid, appropriate amount of distilled water and other raw materials, after the reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com