High performance composite membrane

A composite membrane and performance technology, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve problems such as high cost, time-consuming, and moderate changes in coating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

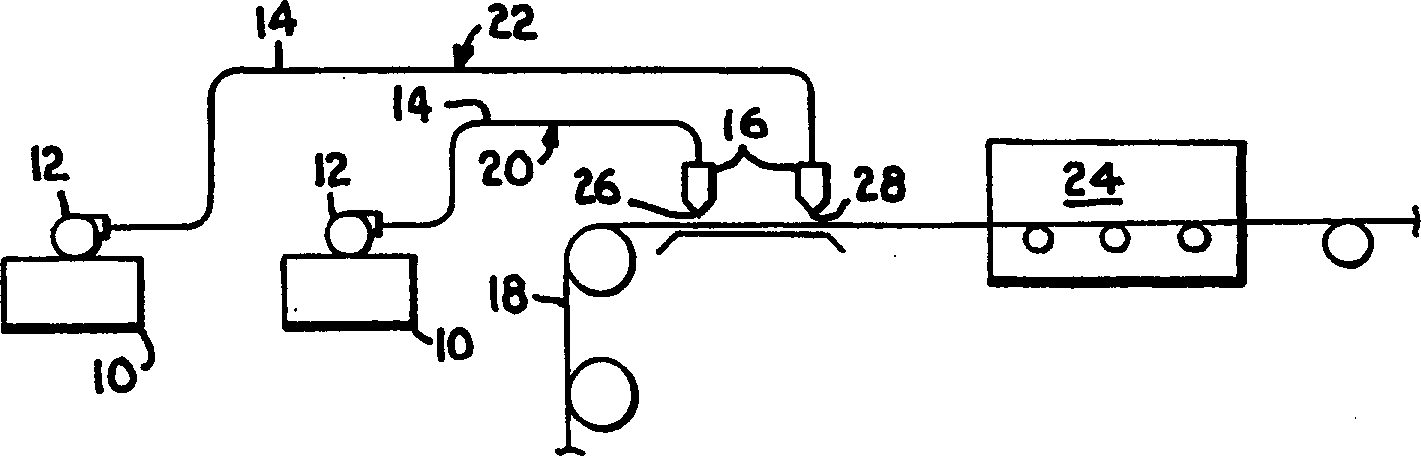

[0061] Example 1: Tandem Compensation Grooved Roll / Slot Die Coating - Reverse Osmosis

[0062]A number of membranes were formed on a polysulfone ultrafiltration matrix (having an average pore size of 0.01 micron) produced by Koch Membrane Systems of Wilmington, Massachusetts (KMS), respectively. In each case, the gravure roll coating was first compensated with a 2% by weight aqueous solution of m-phenylenediamine (MPD) with 0.15% by weight of sodium lauryl sulfate as a surfactant. Subsequent solvent layers were applied wet-wet with a slot die in tandem with the compensating grooved roll. The solvent layer included 1% by weight trimelliticoyl chloride (TMC) in hexane, VM&P Naphtha HC co-solvent composition. The concentration or dry coverage of the MPD and TMC was varied with a high precision cavity pump. The web speed used was varied between 65 and 200 ft / min (20 and 60 m / min). The dry bulb temperature was varied between 50 and 80°C.

[0063] Table 1 shows the results of ex...

Embodiment 2

[0068] Example 2: Tandem Slot Die Coating - Reverse Osmosis

[0069] This example illustrates the effect of small changes in the equimolar or stoichiometric ratio between MPD and TMC functional groups on the performance of reverse osmosis membranes obtained by tandem slot die coating. The optimal stoichiometry of MPD and TMC is shown in Table 2.

[0070] As in Example 1, membranes were formed on a KMS polysulfone ultrafiltration matrix with an average pore size of 0.1 micron. The substrates were initially slot die coated with a 3% by weight aqueous solution of MPD with 0.15% by weight sodium lauryl sulfate surfactant. As in Example 1, subsequent solvent layers were coated wet-wet with a second slot die in tandem with the first slot die. This solvent layer contained 1% TMC in hexane and VM & PNaphthaHC co-solvent composition. The dry coating speed is achieved with a high precision cavity pump. As can be seen from Table 2 below, varying the web speed from 65 to 200 fpm did n...

Embodiment 3

[0076] Example 3: Tandem Slot Die Coating - Reverse Osmosis

[0077] Table 3 provides additional tests of the effect of dry coverage of components on the flux and rejection characteristics of interfacially polymerized reverse osmosis membranes under the test conditions shown in Example 2.

[0078] table 3

[0079] dry coverage

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com