Lyophobic film coating part, liquid spraying device and member

A technology of jetting device and liquid jetting head, applied in the direction of coating, electrical components, layered products, etc., can solve the problem that ink is difficult to guide through or reach, achieve excellent lyophobicity, high density, and reduce gear operation failures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

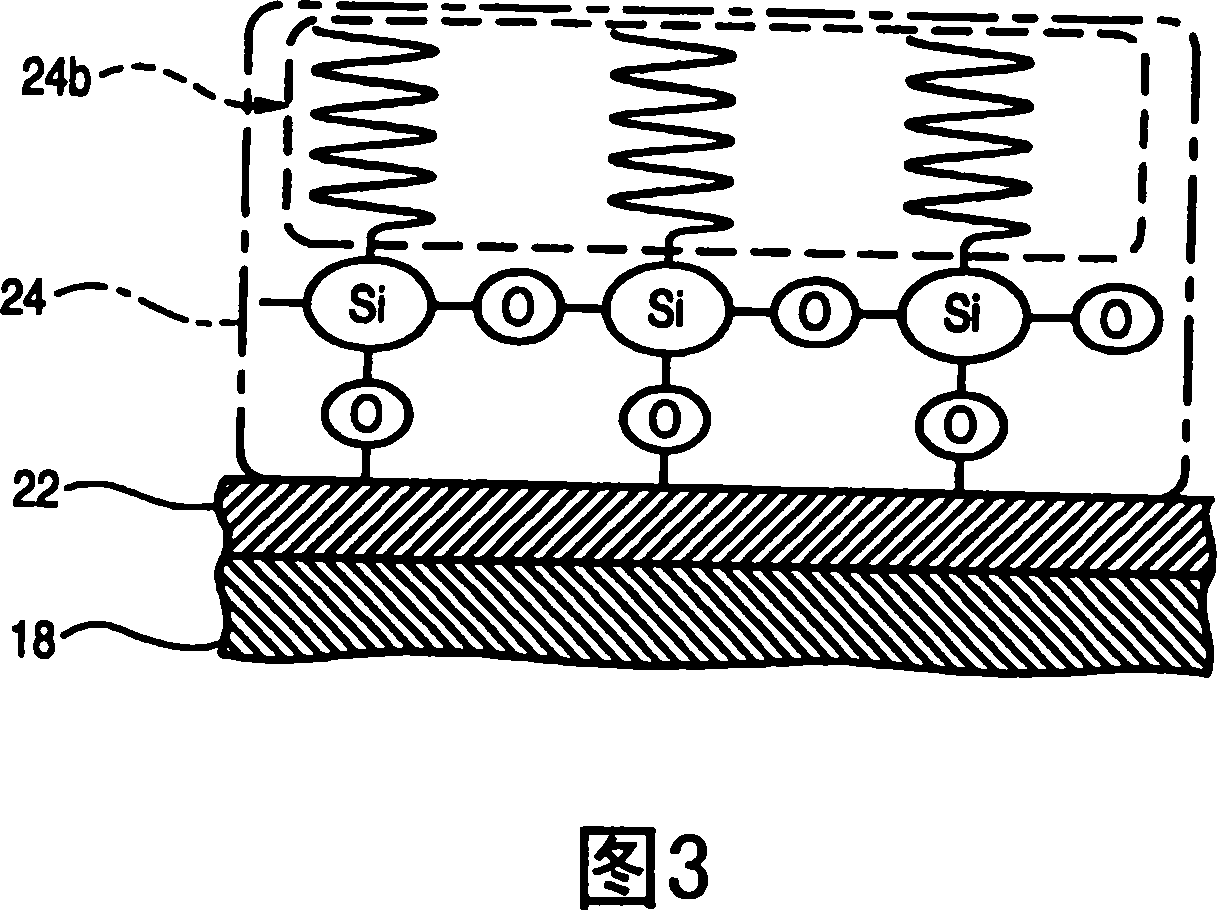

[0095] Referring to preferred embodiments of the present invention, the lyophobic film coating part, the member of the liquid ejection device, the nozzle plate of the liquid ejection head, the liquid ejection head and the liquid ejection device of the present invention will be described in more detail below.

[0096] A method of forming an undercoat film and a metal alkoxide film described below is an embodiment of the present invention in which a nozzle plate of a liquid ejection head serving as a substrate and formed of stainless steel is to be coated with a lyophobic film. However, the present invention is not limited thereto.

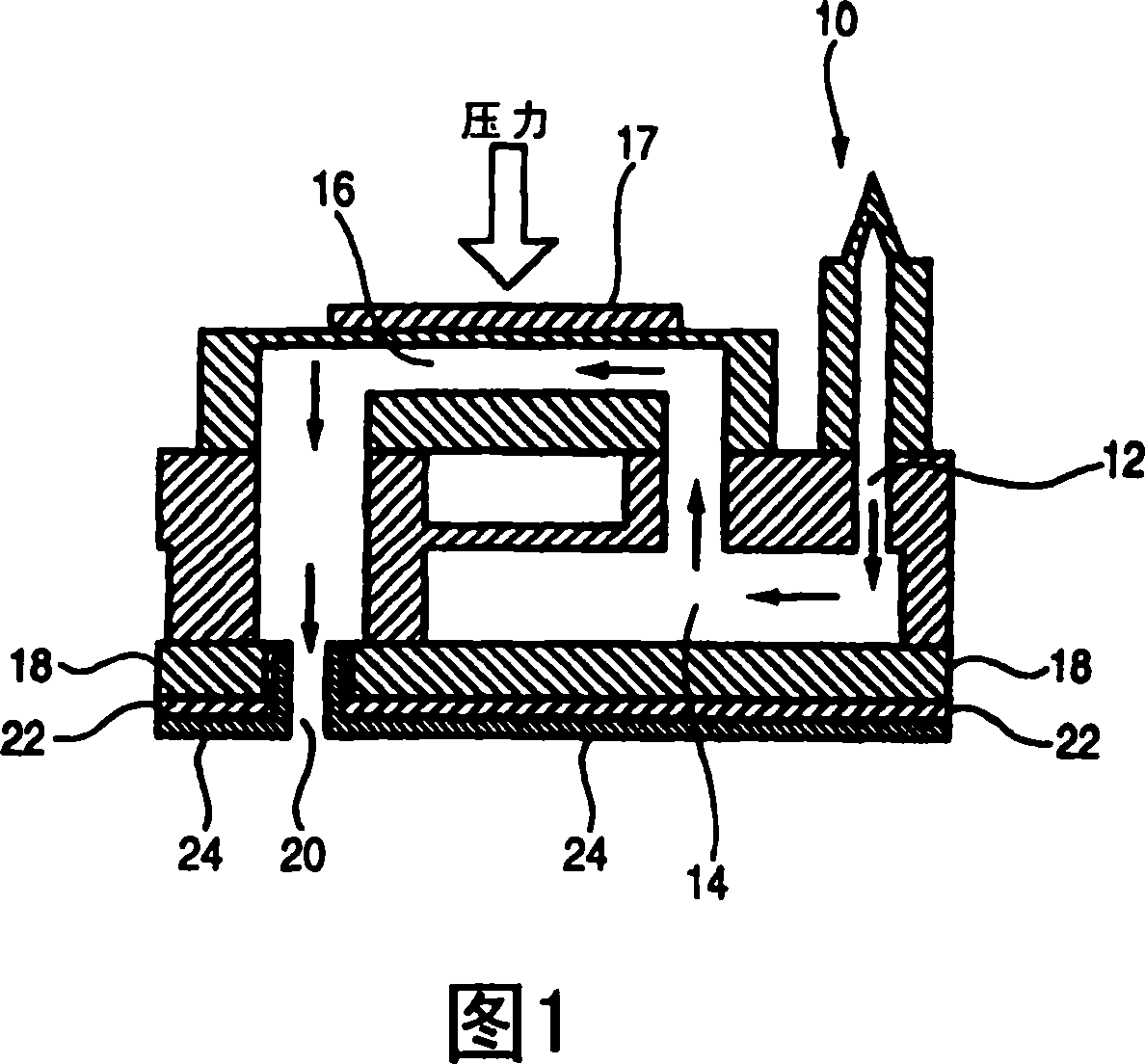

[0097] 1 shows a cross-sectional view of an inkjet printer head 10, which is a liquid ejection head (a part of a liquid ejection device), using ink droplets as liquid droplets to be ejected through nozzle openings. An example. The inkjet printer head 10 has an ink guide groove 12 through which ink is introduced into the inside of the head. The ink...

PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com