Connecting structure of grounded fitting for stitch jack board

A technology for socket boards and accessories, applied in the direction of connection, connection parts protective grounding/shielding device, electrical components, etc., can solve the problems of mold enlargement, ground terminal growth, deformation, etc., to achieve reliable electrical connection and ensure electrical connection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

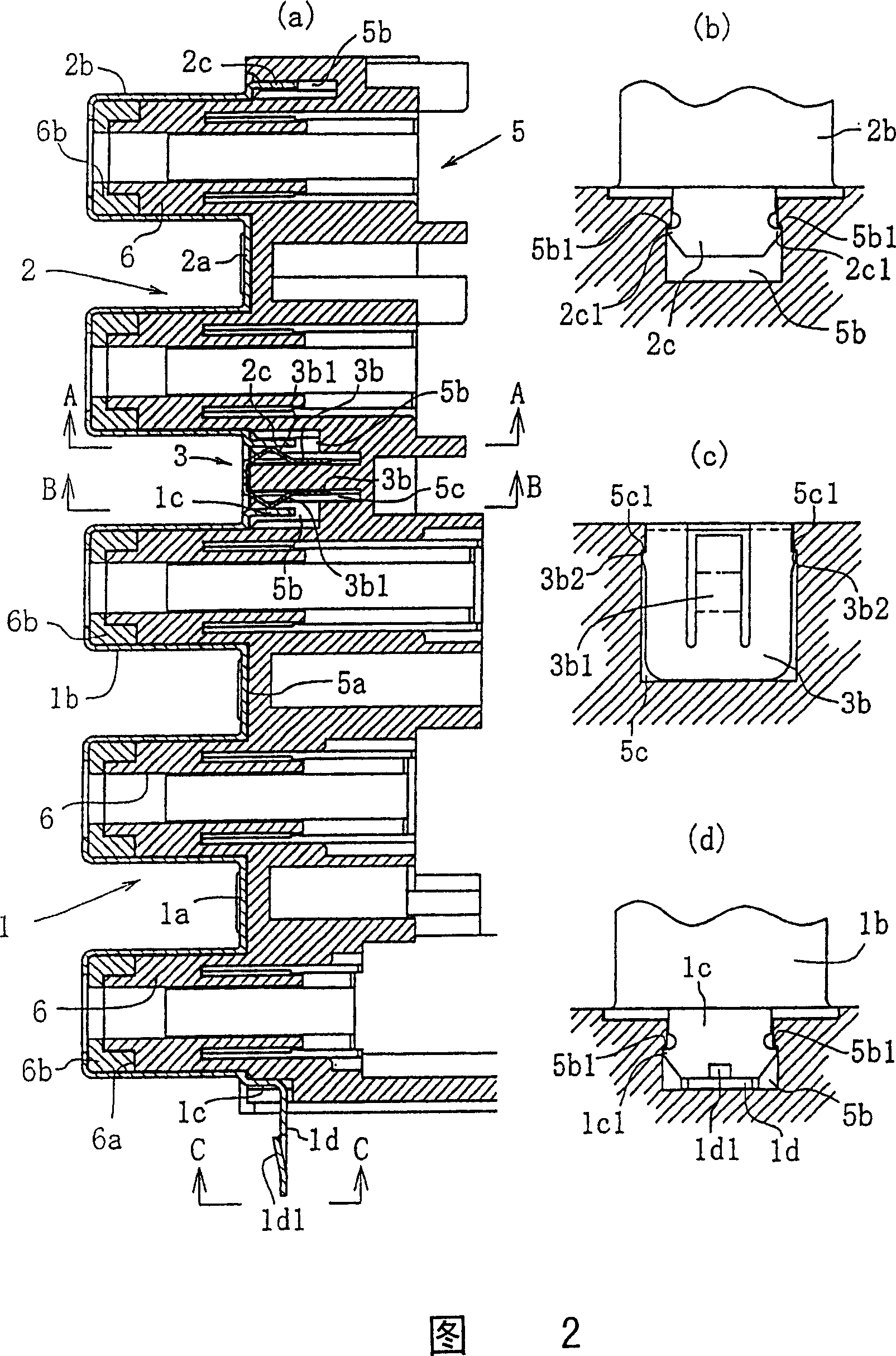

[0043] According to an embodiment, referring to the accompanying drawings, the embodiment of the present invention is described in detail as follows.

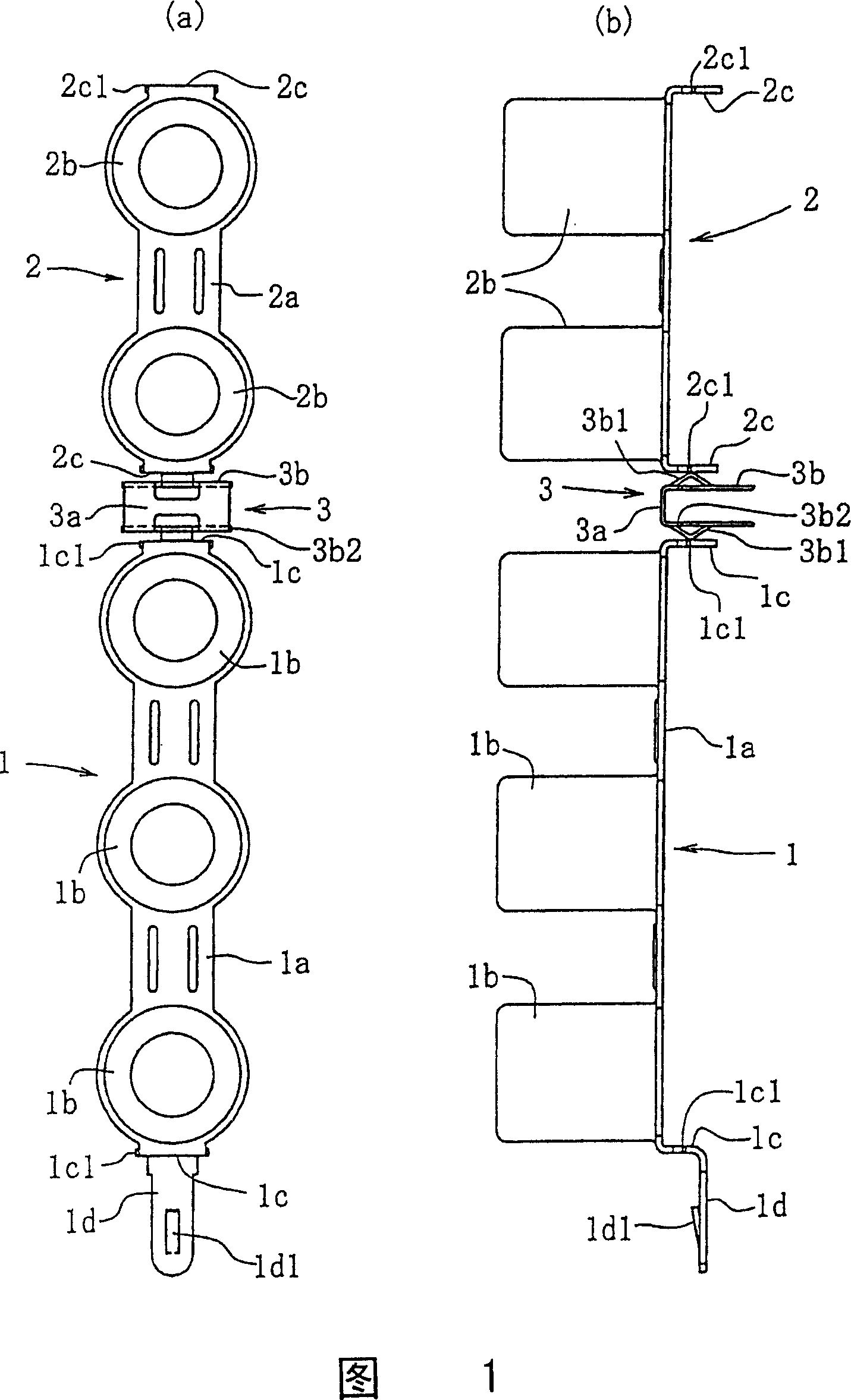

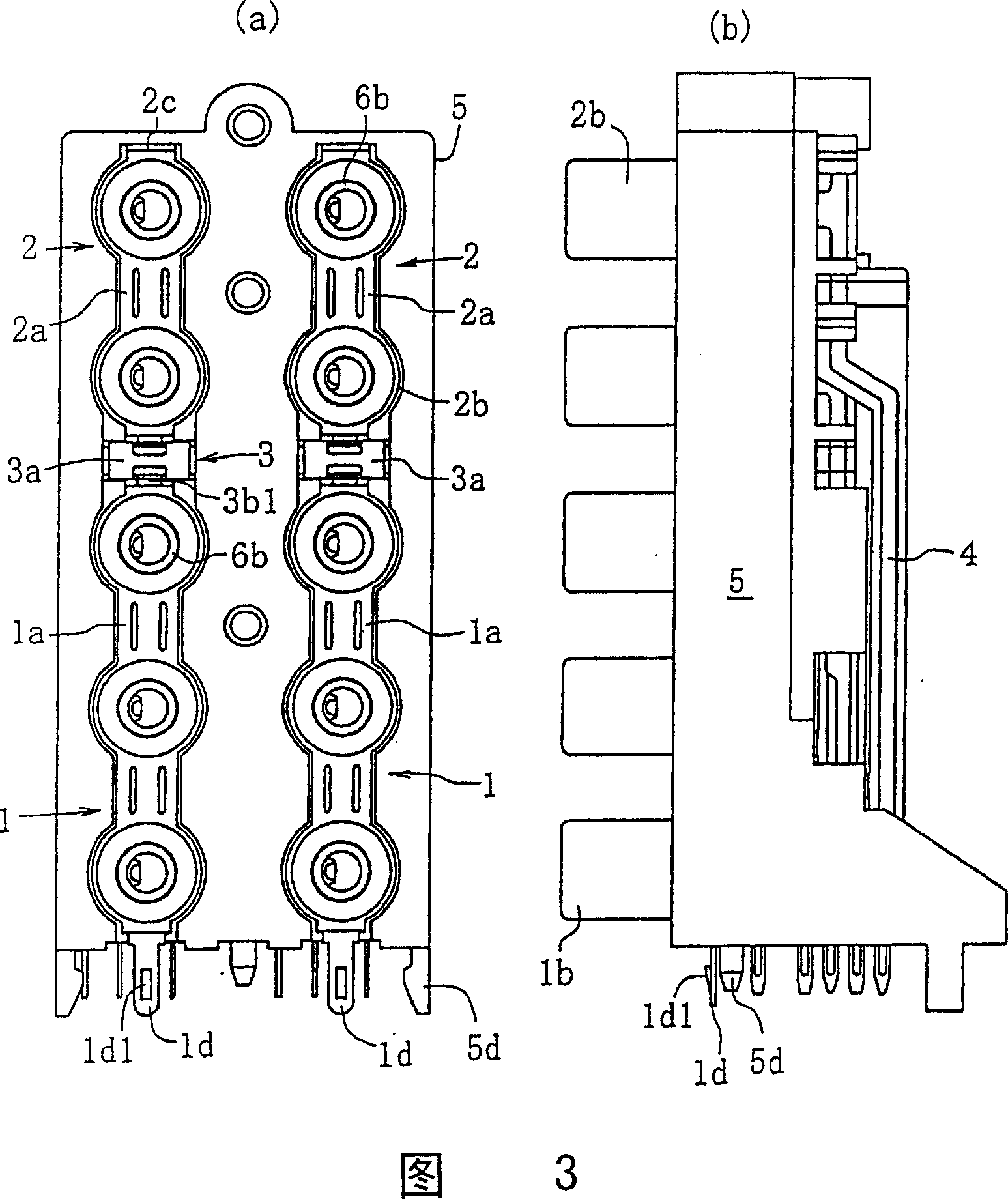

[0044] This embodiment is about the pin jacking board applicable to the connection structure of the ground fitting of the pin jacking board of the present invention, as shown in Figure 1 (a), (b), Figure 3 (a), (b) and Figure 7 (a) , as shown in (b), including: 3-connected grounding fittings 1; double-connected grounding fittings 2; terminal components 3 inserted therebetween; signal terminals 4, 4... integrally formed with unillustrated tabs; and setting these shells 5.

[0045] As shown in Figure 1 (a), (b) and Figure 5 (a), (b), the aforementioned 3-connected grounding fitting 1 includes: a strip-shaped base 1a; 3 conductive covers 1b, 1b erected in a row at regular intervals , 1b; engaging pieces 1c, 1c bent at right angles below both ends of the strip-shaped base 1a;

[0046] The strip-shaped base 1a is a strip-shaped co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com