Yarn strap coiling machine and method thereof

A coiler and sliver technology, which is applied in the directions of transportation and packaging, function indication, and delivery of filamentous materials, etc. It can solve the problem of poor coiling style, problem of gap setting, and no consideration of free length. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

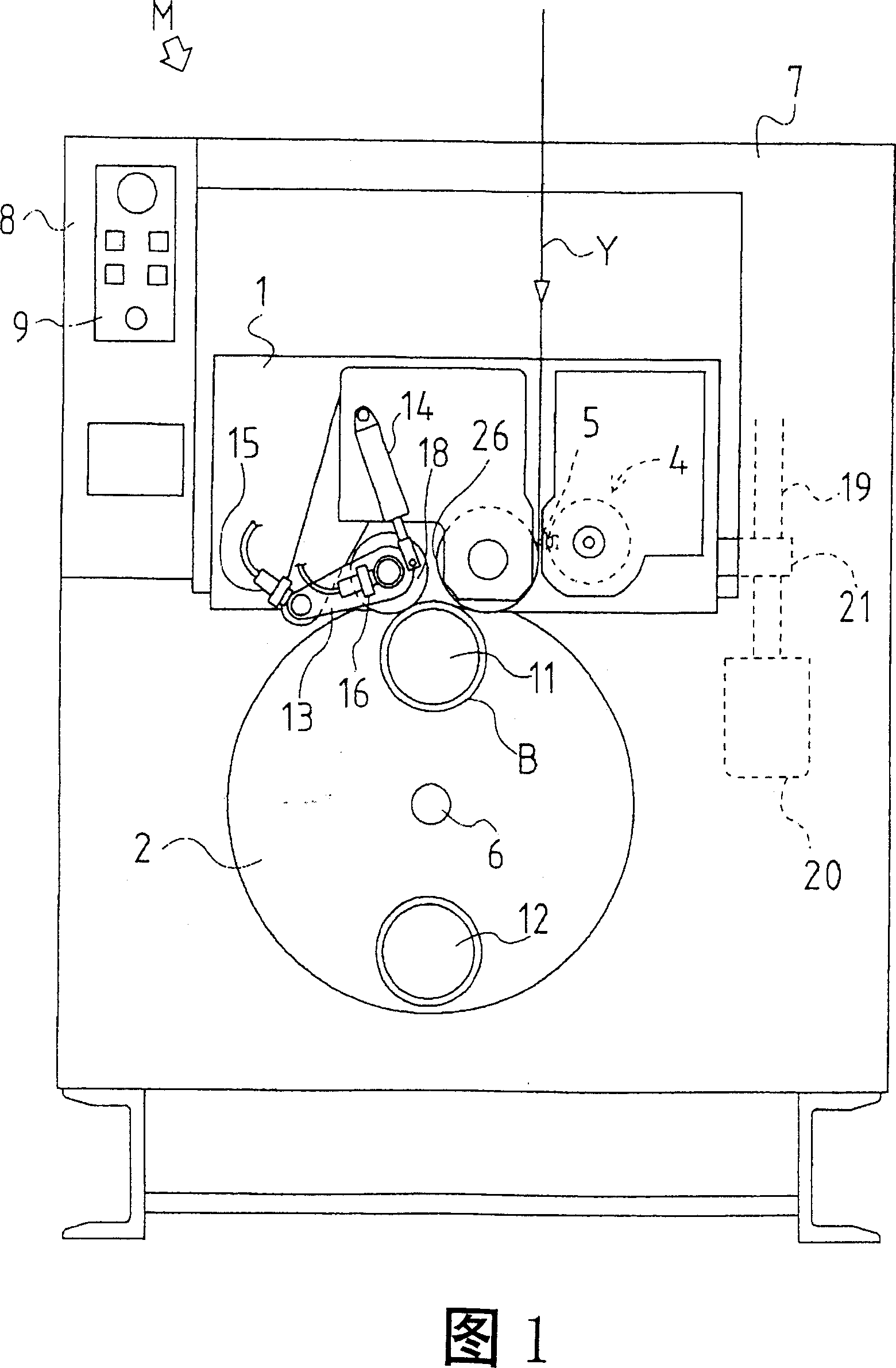

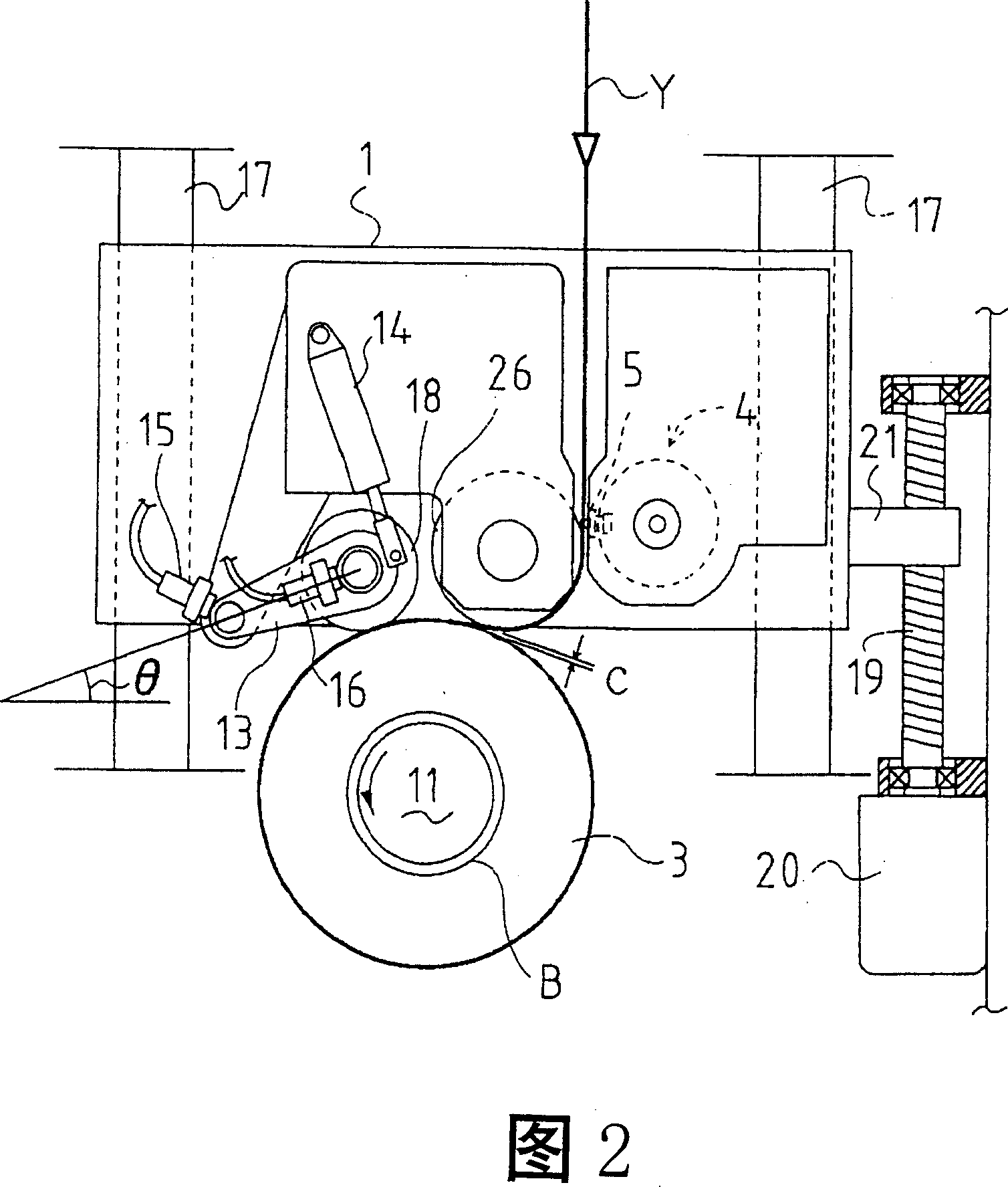

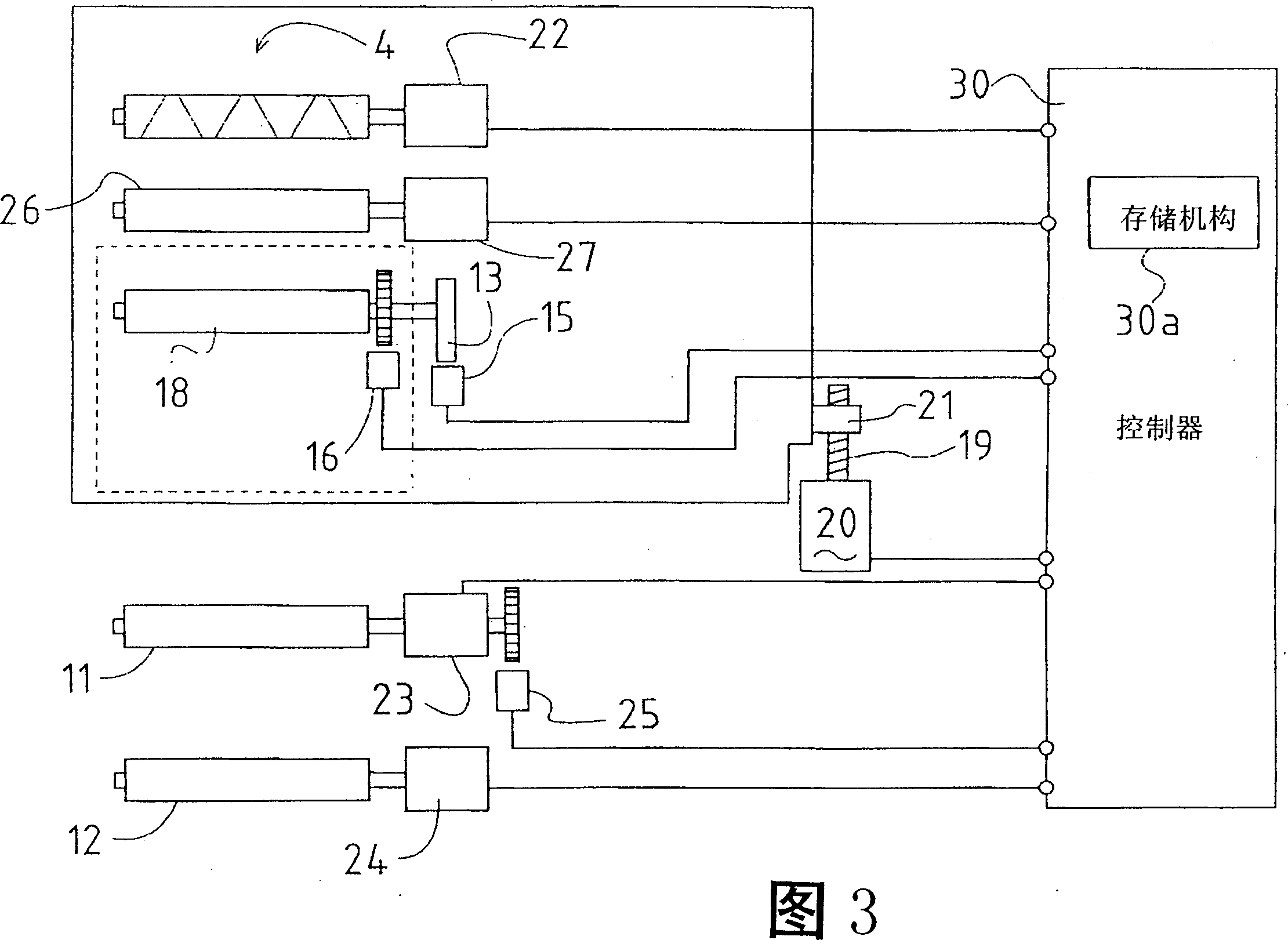

[0038] Fig. 1 is an overall front view of a coiler for elastic yarn. This type of sliver coiler is used for coiling stretchable elastic yarn such as urethane rubber. Fig. 2 is an enlarged front view showing the main structural parts of the slide box. Fig. 3 is a diagram of a control system of a sliver winder. Fig. 4 is a schematic diagram showing the relationship among package diameters, gaps, and contact roller positions. Fig. 5 is a schematic diagram showing the relationship between the gap amount formed between the yarn feed roller and the package, and the free length of the yarn drawn from the feed roller to be wound on the package. Fig. 6 is a schematic diagram showing the relationship between the diameter of the package and the gap when the basic operation is performed with a small gap and the control is performed so that a large gap appears intermittently. Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com