Method for producing low water peak fiber

A manufacturing method, low water peak technology, applied in the direction of manufacturing tools, glass manufacturing equipment, glass fiber products, etc., can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

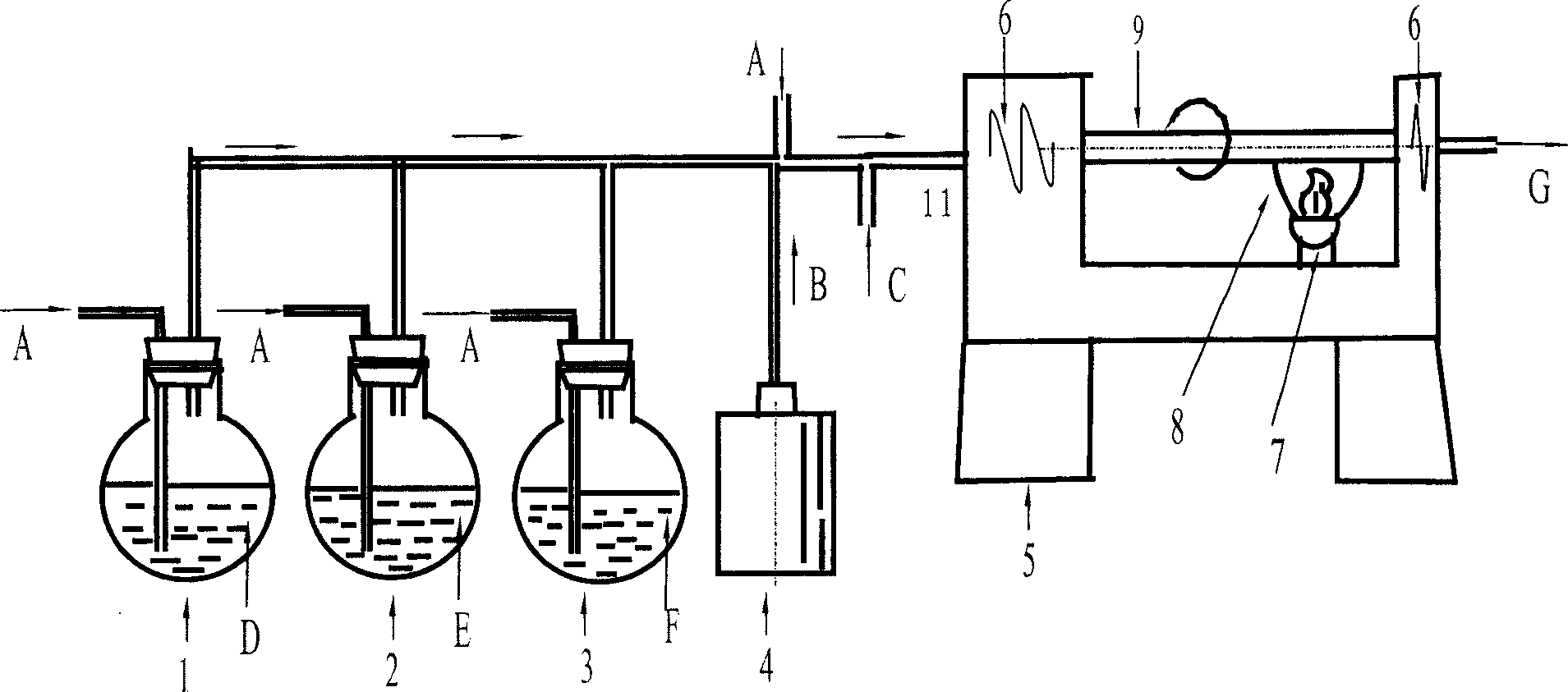

Embodiment 1

[0087] In a production workshop with a temperature of 25°C, a relative humidity of 5% provided by dry air, and a cleanliness level of 1000 (that is, the cleanliness level M4.5 set by the US Federal Standard), the high-purity raw material Freon / SF 6 , The high-purity oxygen mixed gas is introduced into the quartz substrate tube with a hydroxyl content of 10ppb placed on the MCVD deposition lathe through a sealed pipeline, and the inner wall of the quartz substrate tube is corroded and dehydroxylated at a temperature of 1800°C to reduce the inner surface of the quartz substrate tube. The hydroxyl content of the wall. Then, pass high-purity SiCl 4 , POCl 3 , high-purity oxygen, chlorine, and helium mixed gas, the mixed gas reacts at a temperature of 1350 ° C and deposits a certain thickness of loose-structured powder (Soot) on the inner wall of the quartz substrate tube. Subsequently, at a temperature of 1180° C., after purging with high-purity helium, 4% deuterium (4% D 2 +96...

Embodiment 2

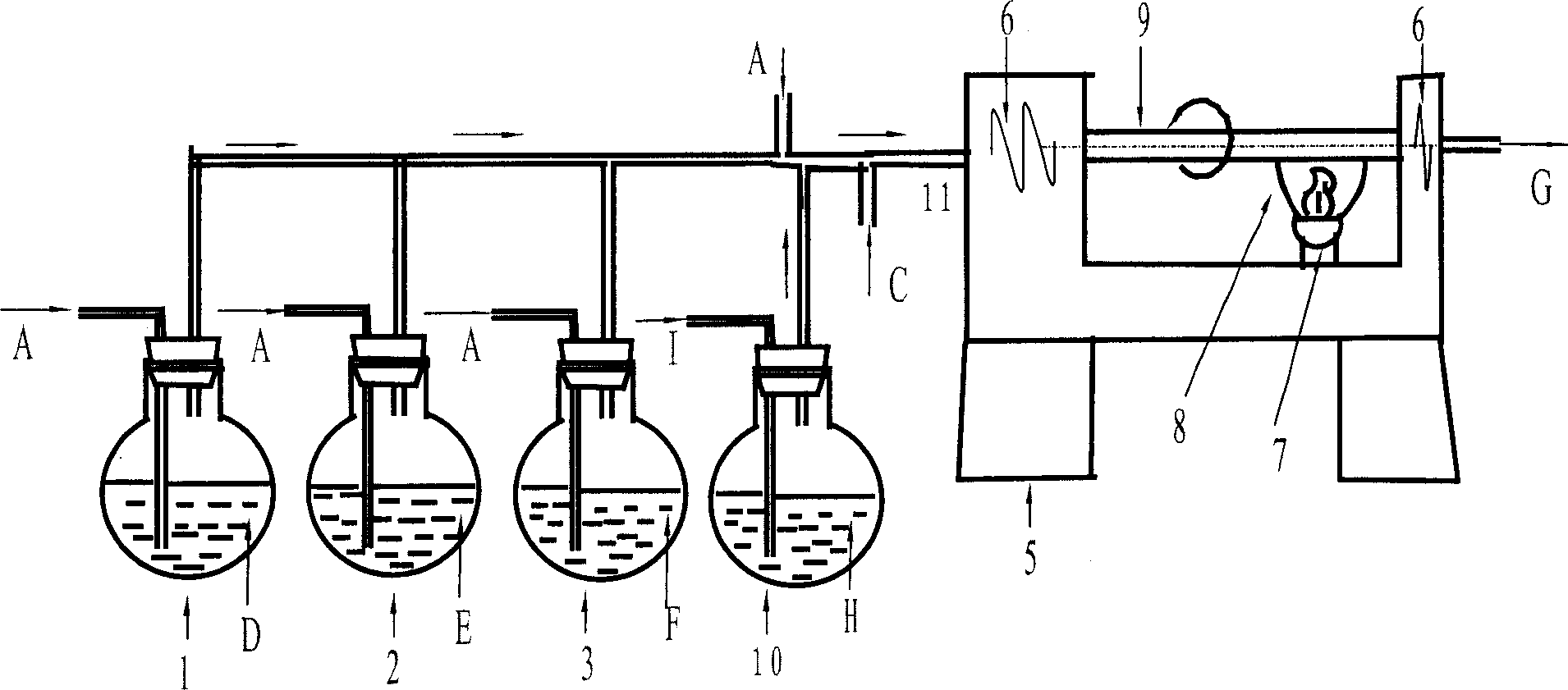

[0094] In a production workshop with a temperature of 25°C, a relative humidity of 10% provided by dry air, and a cleanliness level of 1000 (that is, the cleanliness level M4.5 set by the US Federal Standard), the high-purity raw material Freon / SF 6 The mixed gas of high-purity oxygen is introduced into the quartz substrate tube with a hydroxyl content of 10ppb placed on the MCVD deposition lathe through a sealed pipeline, and the inner wall of the quartz substrate tube is corroded and dehydroxylated at a temperature of 1800 ° C to reduce the quartz substrate. Hydroxyl content of the inner wall of the tube. Then, introduce high-purity SiCl 4 , POCl 3 , high-purity oxygen, chlorine, and helium mixed gas, the mixed gas reacts at a temperature of 1380 ° C and deposits a certain thickness of loose-structured powder (Soot) on the inner wall of the quartz substrate tube. After the high-purity helium is purged, at a temperature of 1200 ° C, heavy water (D 2 O) mixed gas, the Soot ...

Embodiment 3

[0101] In a production workshop with a temperature of 25°C, a relative humidity of 15% provided by dry air, and a cleanliness level of 1000 (that is, the cleanliness level M4.5 set by the US Federal Standard), the high-purity raw material Freon / SF 6 The mixed gas of high-purity oxygen is introduced into the quartz substrate tube with a hydroxyl content of 10ppb placed on the MCVD deposition lathe through a sealed pipeline, and the inner wall of the quartz substrate tube is corroded and dehydroxylated at a temperature of 1800 ° C to reduce the quartz substrate. Hydroxyl content of the inner wall of the tube. Subsequently, at a temperature of 1200°C, after purging with high-purity helium, 2% deuterium (2% D 2 +98% He) mixed gas dehydrates and deuterium-hydrogen exchange the Soot deposited on the inner wall of the quartz substrate tube, and the treatment time is 30 minutes. Soot, which has been fully dehydrated and deuterium-hydrogen exchanged, is vitrified at a temperature of 1...

PUM

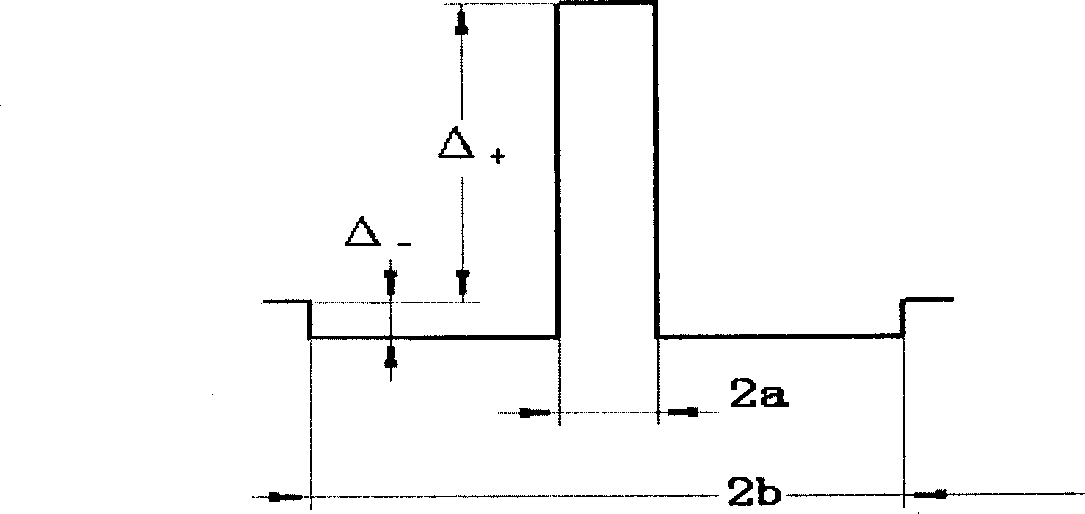

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com