Process and device for forming and producing self-adhesive water-proof coiled material

A waterproof membrane and forming equipment technology, which is applied in the direction of layered products, lamination devices, lamination, etc., can solve the problems of poor quality and aesthetics of waterproof membranes, and achieve smooth surfaces, improved quality, and uniform blanking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

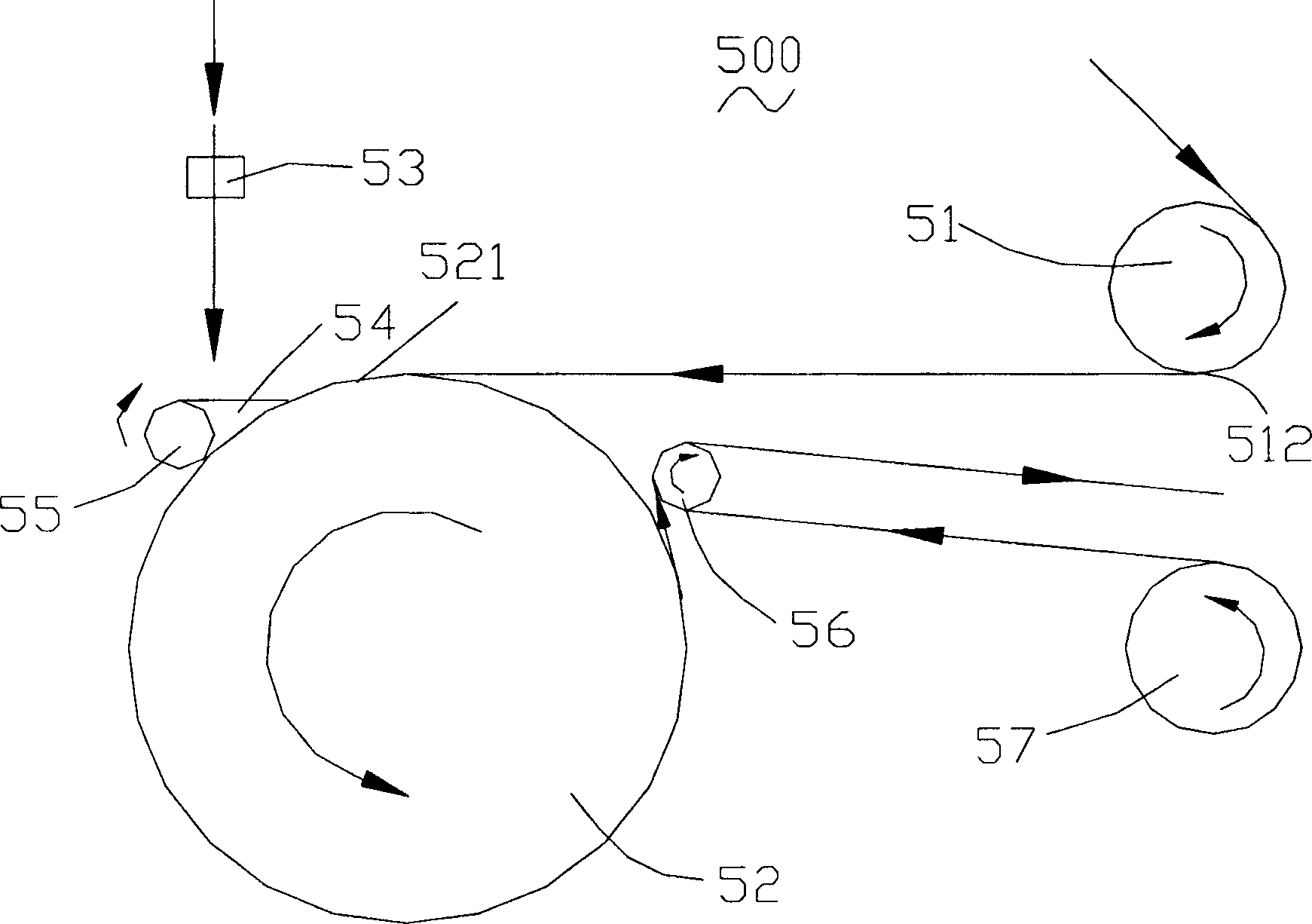

[0027] Please refer to image 3 As shown, the waterproof coiled material forming equipment 500 of the present invention includes a large cooling roll 52, a raw material coil conveying device 51 arranged on one side of the large cooling roll 52 and at a certain distance from the large cooling roll 52, and a raw material coil conveying device 51 located The unwinding device 57 and the flattening roll 56 on the same side of the large cooling roll 52, the small flattening hot roll 55 arranged on the other side of the large cooling roll 52, the cloth that is arranged on the small flattening hot roll 55 and the large cooling roll 52 Device and the baffle plate 54 that is arranged on the axial two ends of the space formed between the small flattening hot roller 55 and the large cooling roller 52. The gap at the bottom of the space formed between the small flattening hot roller 55 and the large cooling roller 52 can be adjusted, which is convenient for controlling the thickness of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com