Diffusing and spraying combustion system of IC engine

A spray combustion, internal combustion engine technology, applied in the direction of internal combustion piston engines, charging systems, combustion engines, etc., can solve the problems of short penetrating distance of umbrella-shaped spray, too thick circular distribution of mixed gas, unevenness, etc., and achieve fast spray dispersion speed , Large spatial range of distribution, and the effect of increased power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

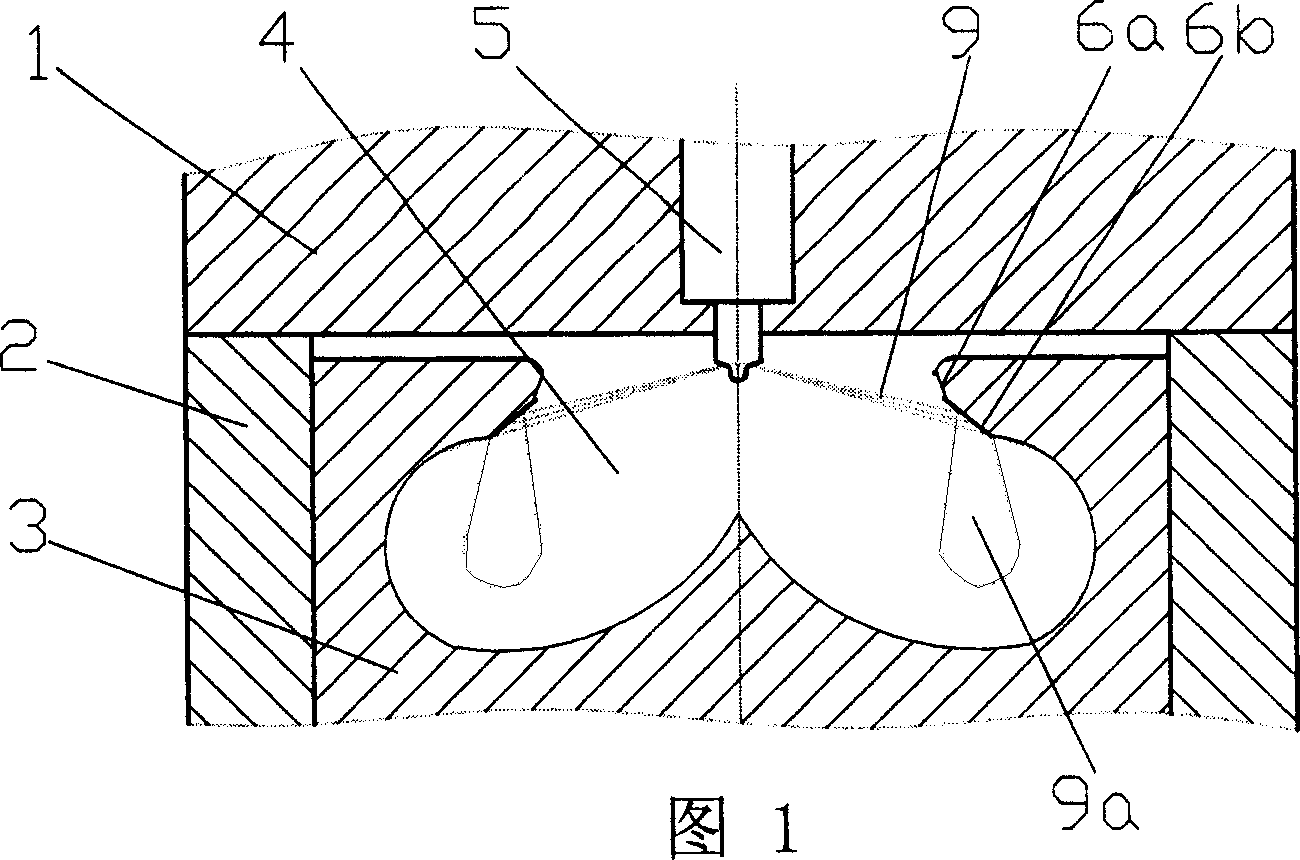

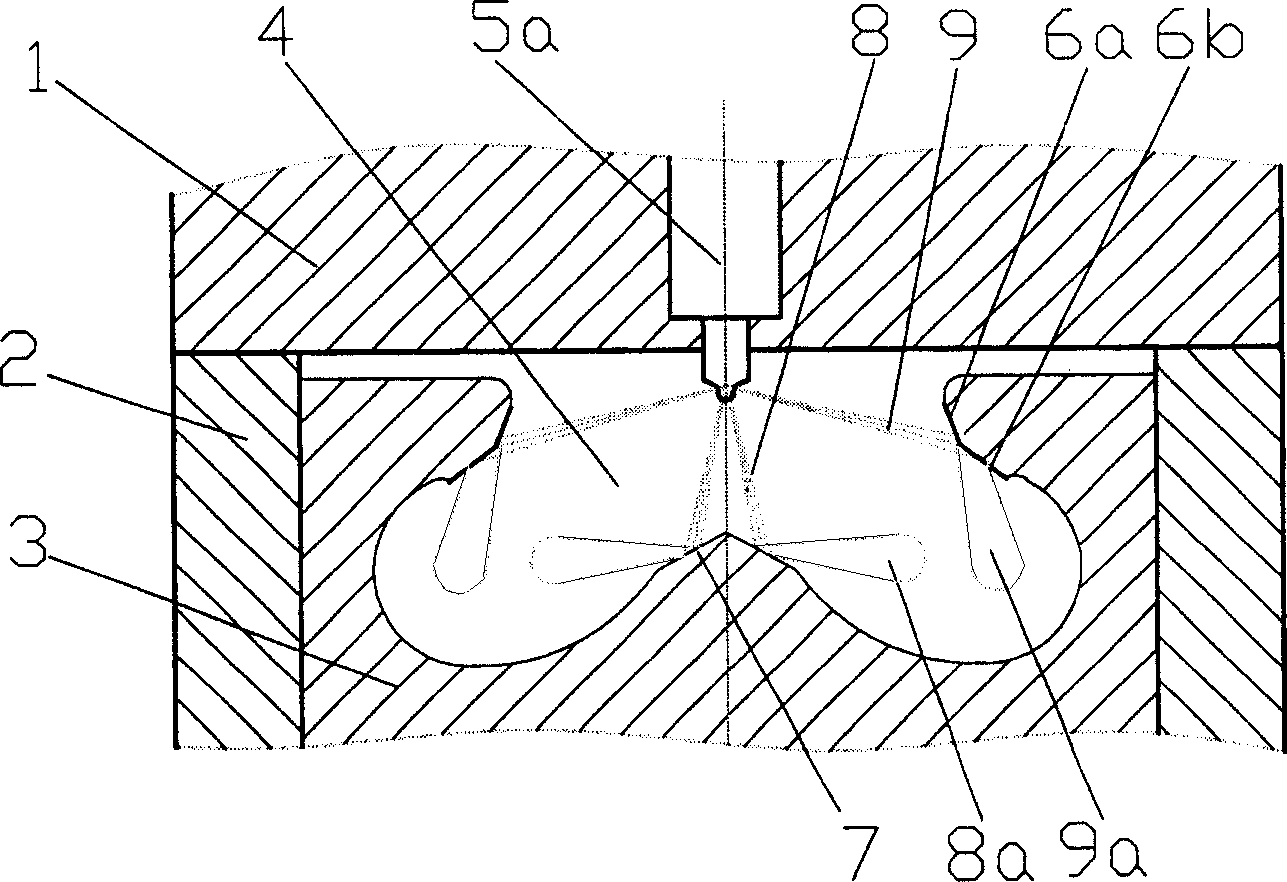

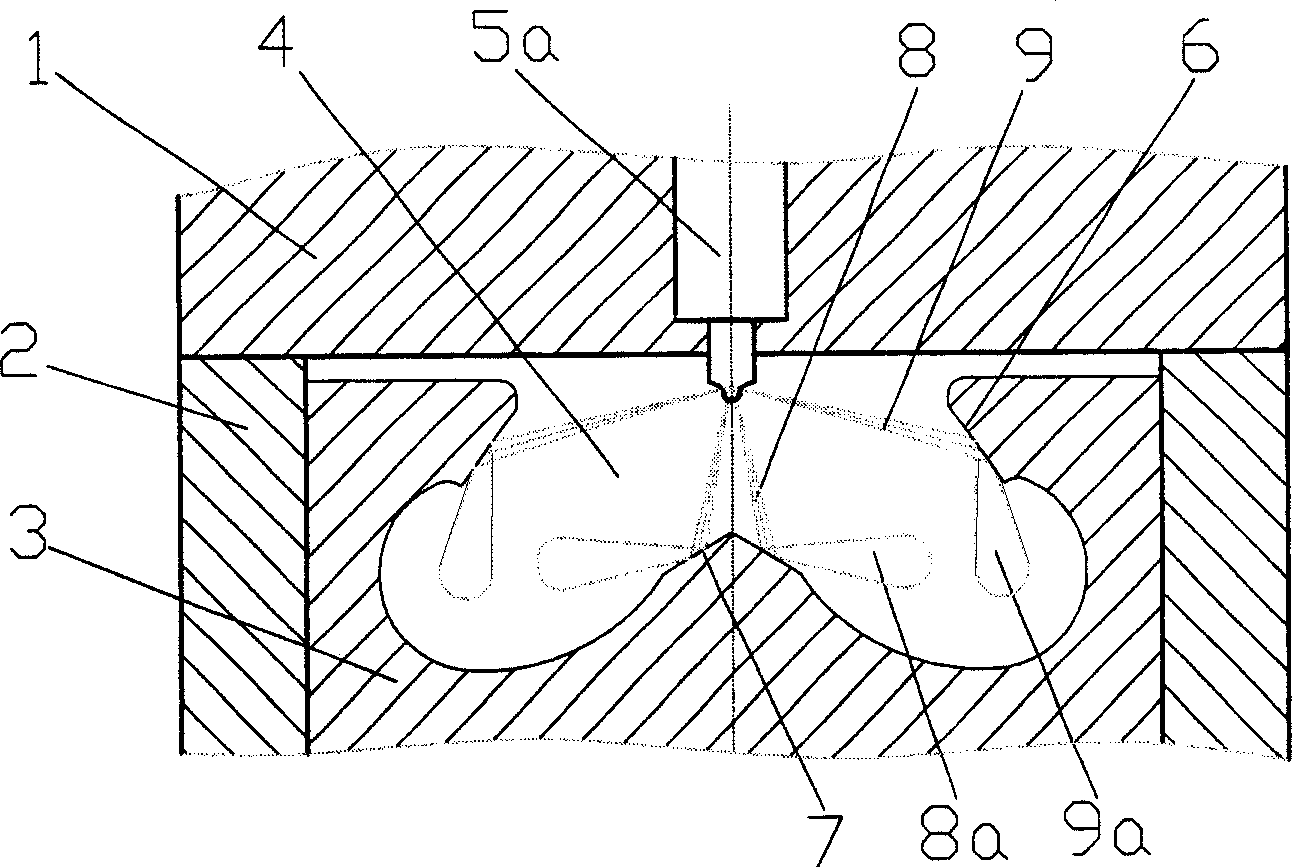

[0011] In the embodiment shown in Figures 1, 2, and 3, a main combustion chamber is composed of a cylinder head 1, a cylinder liner 2 and a piston 3, and the combustion chamber 4 arranged on the top of the piston should cooperate with the oil beam of the injector. , the spray diffusion surface provided at the closing part of the combustion chamber 4 is a conical surface, and the oil beam 9 of the injector is directly sprayed to the conical surface.

[0012] In Fig. 1, the spray diffusion surface at the mouth of the combustion chamber 4 adopts an upper cone surface 6a and a lower cone surface 6b, and the oil beam 9 of the single-row nozzle injector 5 is directly sprayed on the upper cone surface 6a and the lower cone surface 6b , forming a diffused oil beam 9a with a wider distribution range.

[0013] exist figure 2 Among them, the spray diffusion surface at the mouth of the combustion chamber 4 also adopts an upper cone surface 6a and a lower cone surface 6b, and a protrusion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com