Molecular sieve containing secondary structure unit of beta zeolite and its preparing process

A technology of secondary structural units and mesoporous molecular sieves, applied in molecular sieve catalysts, chemical instruments and methods, crystalline aluminosilicate zeolites, etc., to achieve good catalytic cracking reaction activity, improved reaction activity, and good catalytic reaction performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

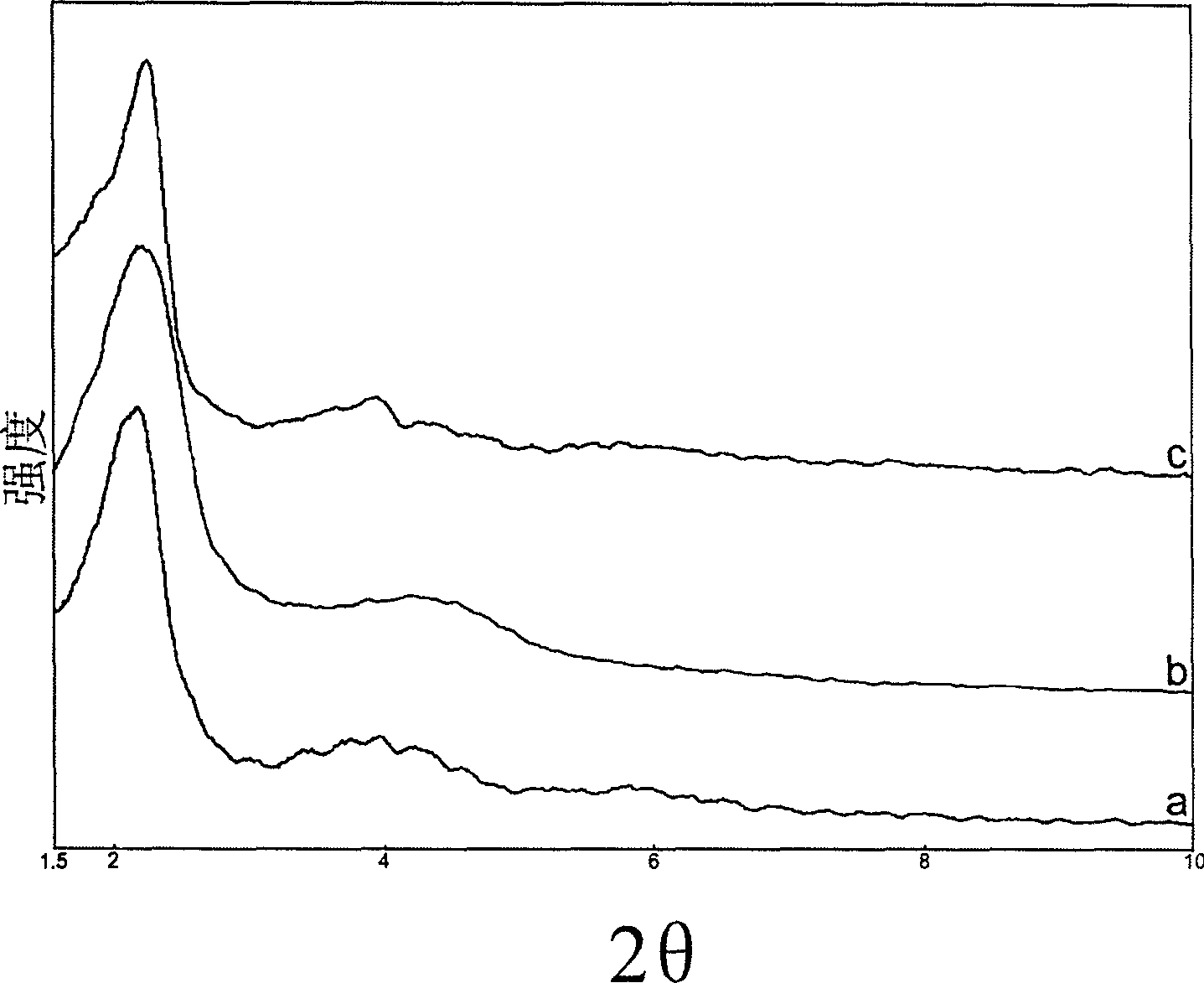

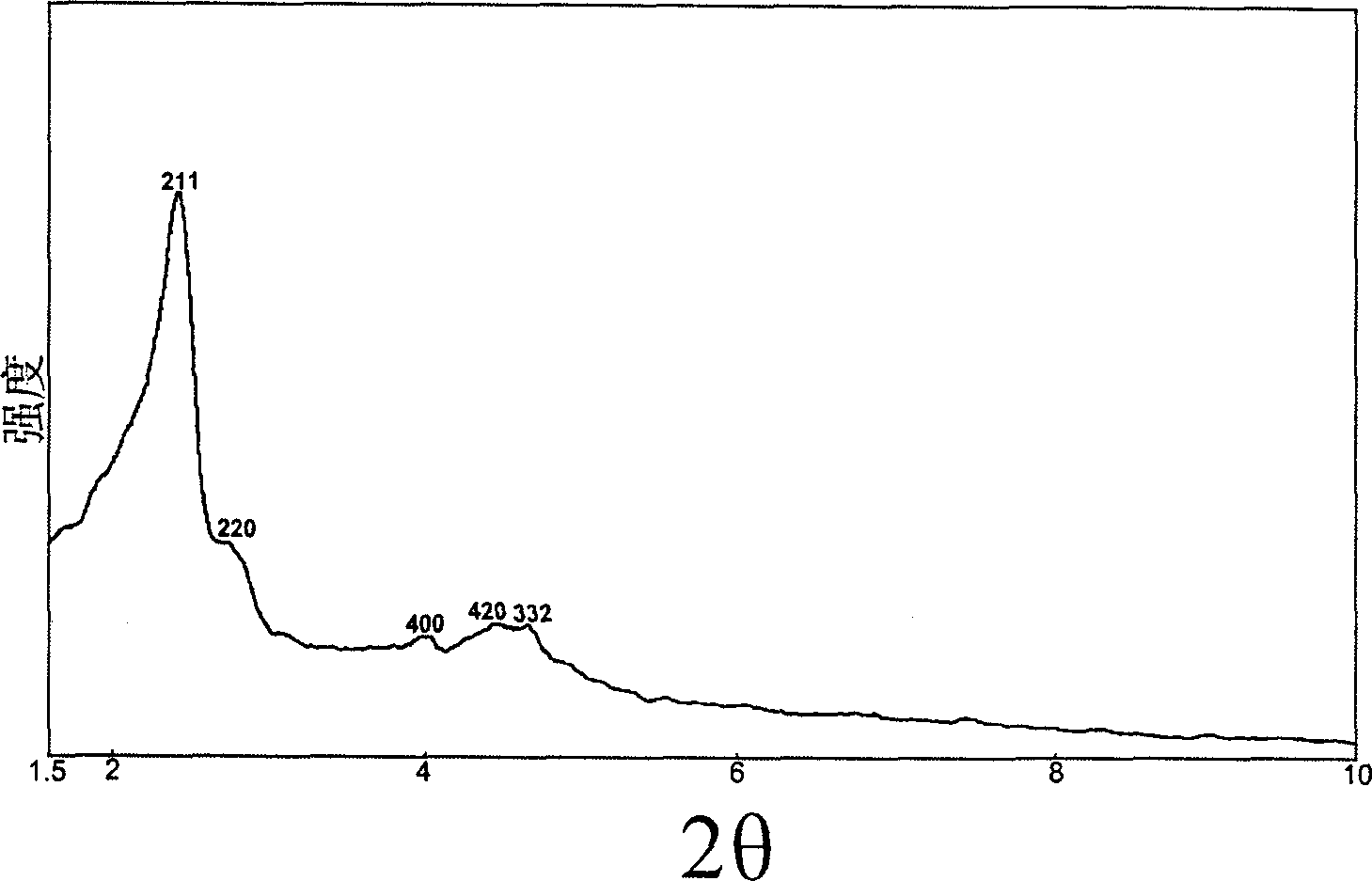

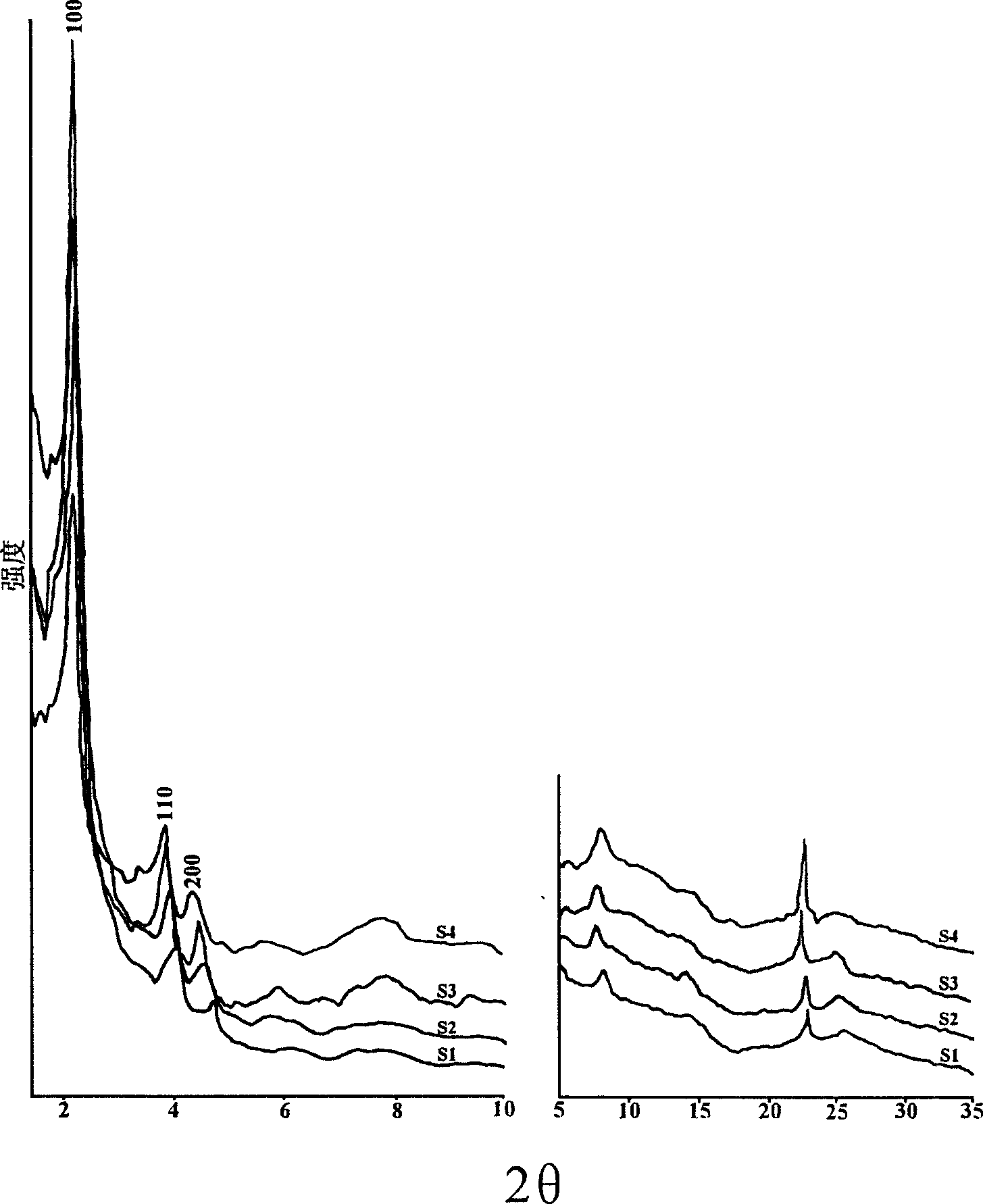

[0024] 0.067g pseudo-boehmite (51wt%Al 2 o 3 ) was dissolved in 10.0g tetraethylammonium hydroxide solution (25wt%), then 2.0g fumed silica was added, stirred evenly, and then packed into a stainless steel reaction kettle with a polytetrafluoroethylene liner, at 140°C The reaction was stirred for 22h. The above-mentioned pretreated sol is dropped into the CTAB solution with a concentration of 15.8wt%. At this time, the molar composition of the synthetic mixture is: SiO 2 : 0.01Al 2 o 3 : 0.25(TEA)2 O :0.28CTAB:39H 2 O. Then adjust the pH to 10.5 with dilute sulfuric acid, and crystallize at 100°C for 48h to obtain SBU-MCM-41 mesoporous molecular sieve (SiO 2 / Al 2 o 3 =91.1).

Embodiment 2

[0026] Weigh 0.1g pseudo-boehmite (51wt% Al 2 o 3 ), was dissolved in 7.0g tetraethylammonium hydroxide solution (25wt%), then added 1.5g fumed silica, stirred evenly and then packed into a stainless steel reactor with a polytetrafluoroethylene liner, at 135 ° C The reaction was stirred for 56h. The above-mentioned pretreated sol is dropped into the CTAB solution with a concentration of 14.1wt%. At this time, the molar composition of the synthetic mixture is: SiO 2 : 0.02Al 2 o 3 :0.23(TEA) 2 O: 0.25CTAB: 53H 2 O. Then adjust the pH to 10.0 with dilute sulfuric acid, and crystallize at 95 ° C for 60 h to obtain SBU-MCM-41 mesoporous molecular sieve (SiO 2 / Al 2 o 3 =47.7).

Embodiment 3

[0028] 0.133g pseudo-boehmite (51wt%Al 2 o 3 ) was dissolved in 5.0g tetraethylammonium hydroxide solution (25wt%), then added 1.0g fumed silicon dioxide, stirred evenly and then packed into a stainless steel reactor with a polytetrafluoroethylene liner, at 145 ° C The reaction was stirred for 124h. The above-mentioned pretreated sol is dropped into the CTAB solution with a concentration of 16.2wt%. At this time, the molar composition of the synthetic mixture is: SiO 2 : 0.04Al 2 o 3 :0.25(TEA) 2 O:0.29CTAB:61H 2 O. Then adjust the pH to 10.5 with dilute sulfuric acid, and crystallize at 105°C for 72h to obtain SBU-MCM-41 mesoporous molecular sieve (SiO 2 / Al 2 o 3 =22.4).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com