Wave length adjustable vertical cavity surface emitting laser diode

一种表面发射激光、垂直腔的技术,应用在激光器、激光器零部件、半导体激光器等方向,能够解决难迅速改变运行温度、激光谐振特性增益损耗多、很难改变发射光波长等问题,达到避免激光谐振增益特性变劣、拓宽波长可调谐区域的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

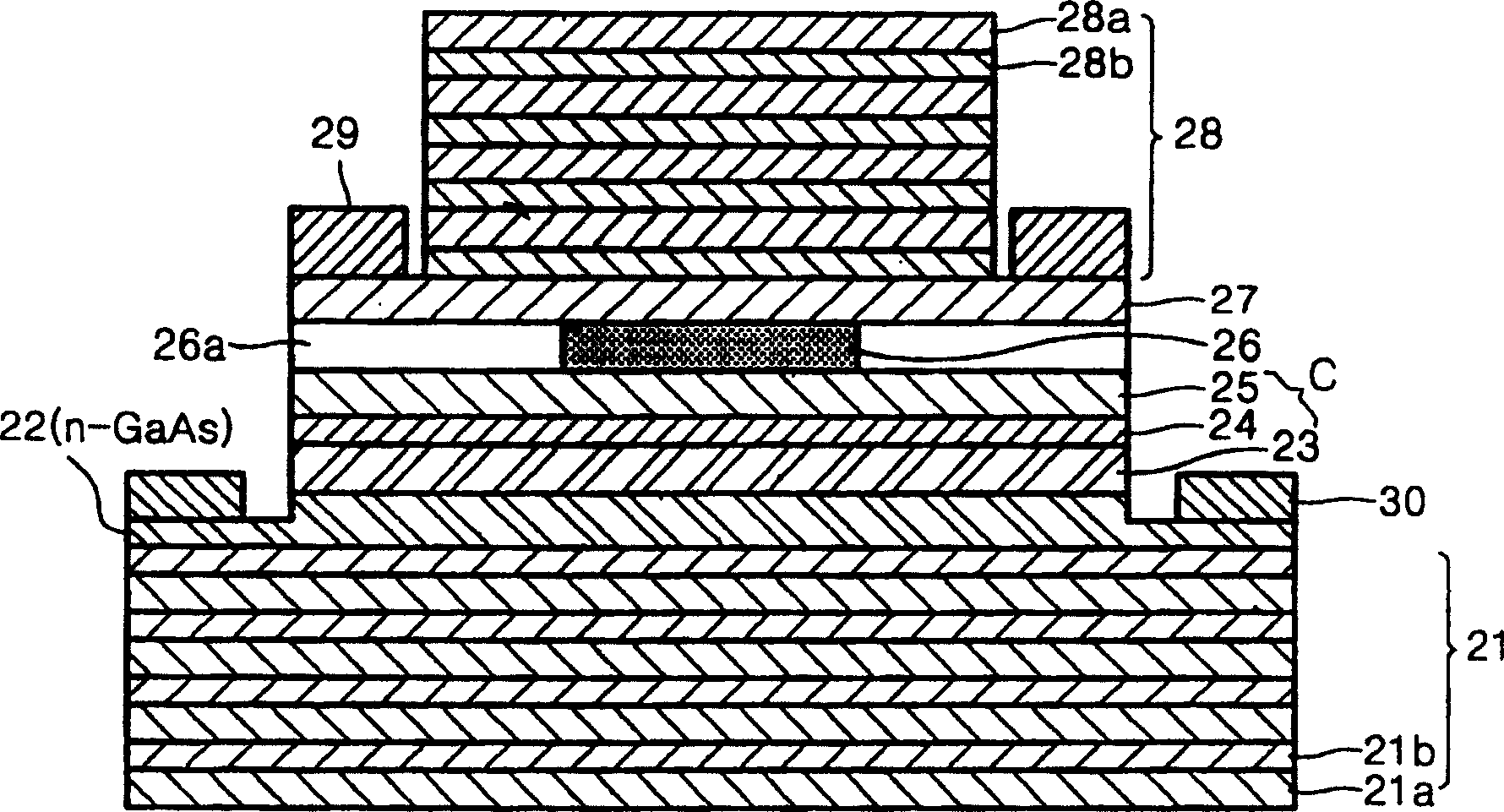

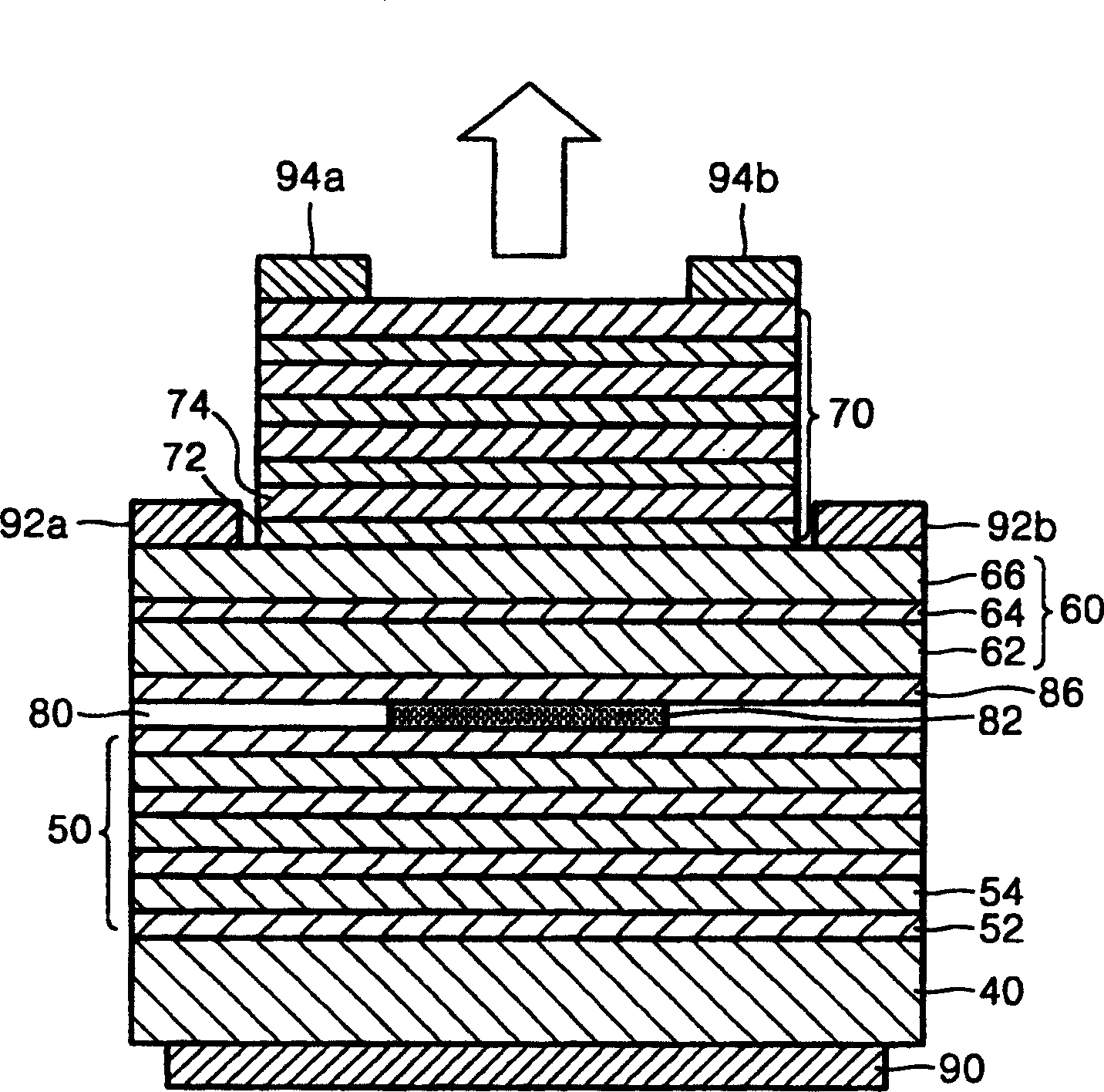

[0018] The wavelength tunable VCSEL in an embodiment of the present invention will be described below with reference to the accompanying drawings. For clarity, the thickness of each layer or each area in the figure has been exaggerated.

[0019] See figure 2 , Reference numeral 40 denotes a substrate, which is a compound semiconductor substrate on which upper and lower distributed Bragg reflectors (DBRs) 50 and 70 and a cavity resonance layer 60 are formed. The lower DBR 50 is formed on the substrate 40. The lower DBR 50 is formed by alternately stacking first and second compound semiconductor layers 52 and 54. The first and second compound semiconductor layers 52 and 54 preferably do not absorb light emitted from the cavity resonance layer 60. Therefore, the energy band gaps of the first and second compound semiconductor layers 52 and 54 are preferably larger than the resonance wavelength. For example, both the first and second compound semiconductor layers 52 and 54 are prefera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com