Method of controlling compression ignition of direct spray type gasoline engine by twice injection

A compression ignition and gasoline engine technology, applied in fuel injection control, electrical control, engine control, etc., can solve the problems of sensitivity to changes in working conditions, low control accuracy, and slow response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

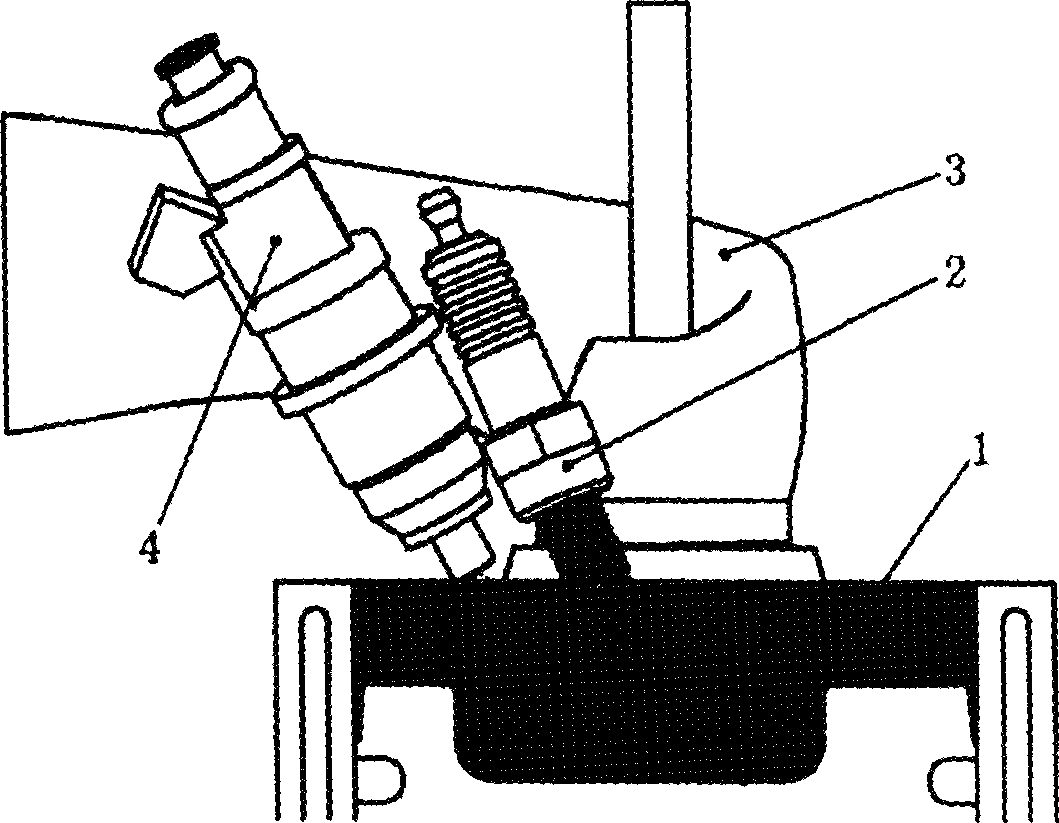

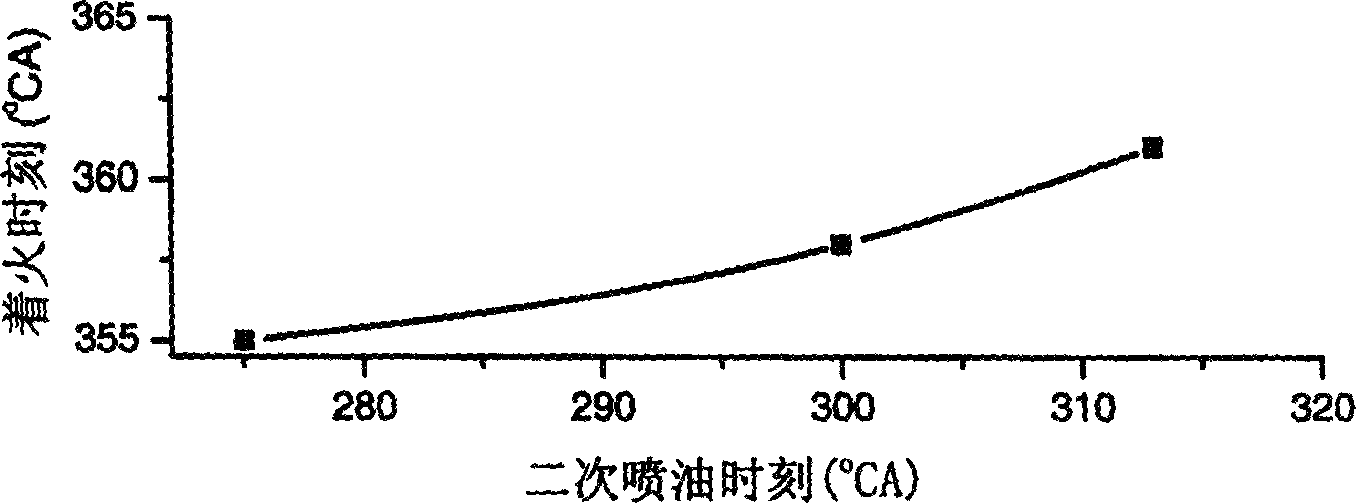

[0016] On an engine with a cylinder diameter of 95 mm, the most commonly used vortex intake method is maintained, and the shape of the combustion chamber is a cylindrical pit with a depth of 10 mm and a diameter-to-depth ratio of 4; the compression ratio is 13, and the cone angle is The 30° high-pressure swirl parachute gasoline electronic control injector adopts two injections. The main test conditions are shown in the table below. According to the fuel injection pulse signal given by the electronic control unit (to control the fuel injection timing and fuel injection volume), the fuel injector performs the first fuel injection in the intake stroke and the second fuel injection in the compression stroke. As a result, two areas with different mixture density and leanness are formed, in which the rich mixture gas is mainly concentrated in the pit of the combustion chamber, and spontaneous ignition occurs first, and the resulting high temperature and high pressure ignites the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com