Production process of high-nitrogen large-grain urea

A kind of large particle urea, production technology technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

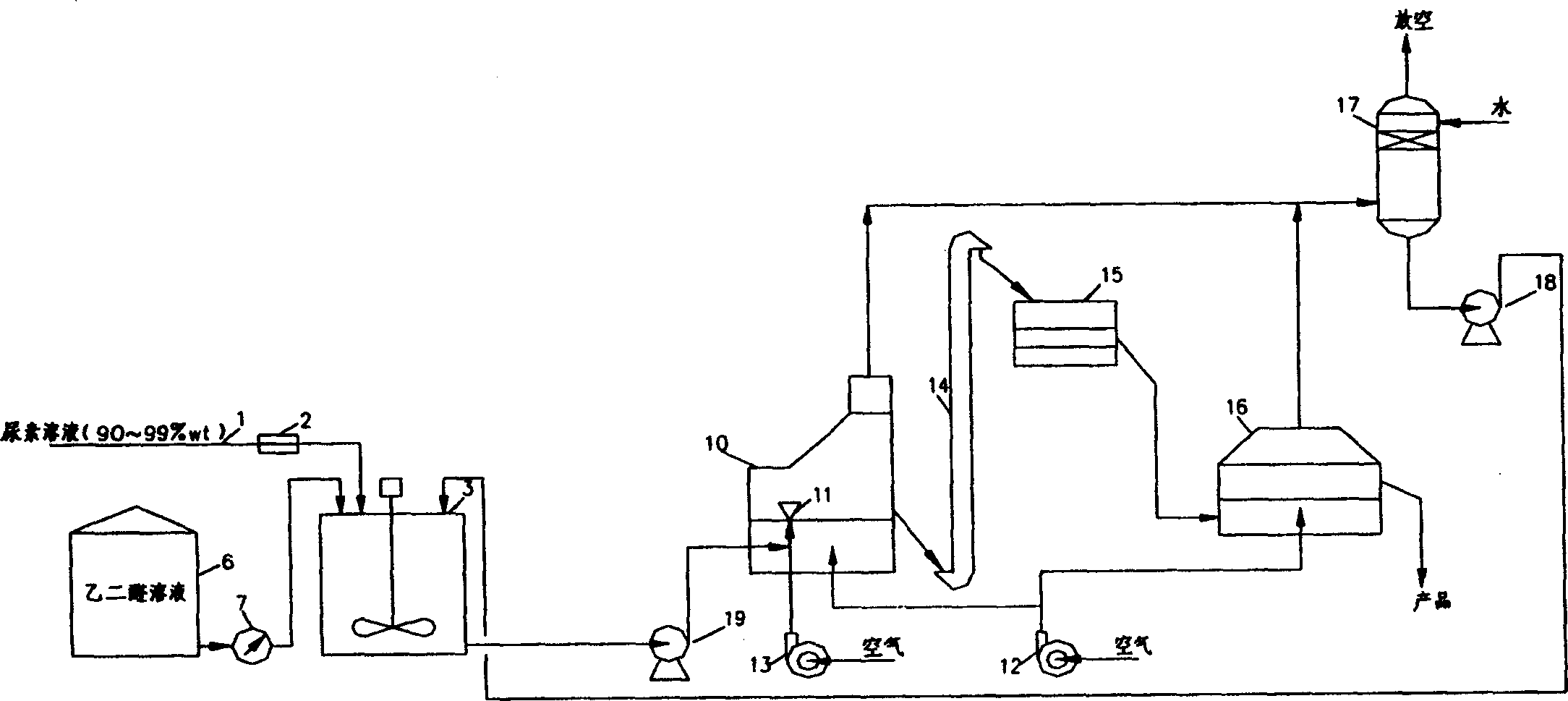

[0041] Refer below figure 1 Describe the content of the present invention in detail.

[0042] The raw material is urea solution with a concentration of 98% (wt) obtained from the urea synthesis and decomposition process, which is metered by the pipeline 1 and the flow meter 2 and then enters the mixing tank 3 .

[0043] In addition, the glyoxal solution is sent into the mixing tank through the glyoxal solution tank 6 and the glyoxal metering pump 7 . Mixing was carried out under conditions of a pressure of 0.15 MPa and a temperature of 132°C. After the above two materials are evenly stirred in the mixing tank, they are sent to the granulator 10 by the urea solution feeding pump 19 for granulation. The weight ratios of the urea solution and the glyoxal solution in the mixing tank are 100 kg and 0.1 kg respectively.

[0044] The granulation system consists of an atomizing fluidized bed granulator, a fluidizing air fan 12, an atomizing air fan 13, and an atomizing nozzle 11. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com