Method for reusing contaminant separated from naphthalenesulfonic acid neutralization wash waste liquor

A technology of pollutants and naphthalenesulfonic acid, which is applied in the direction of neutralizing water/sewage treatment, adding substances to water/sewage treatment, etc., can solve the problems of unutilized active ingredients, large amount of chemical substances, high energy costs, etc., and achieve the elimination of secondary secondary pollution, low production cost and high economic benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

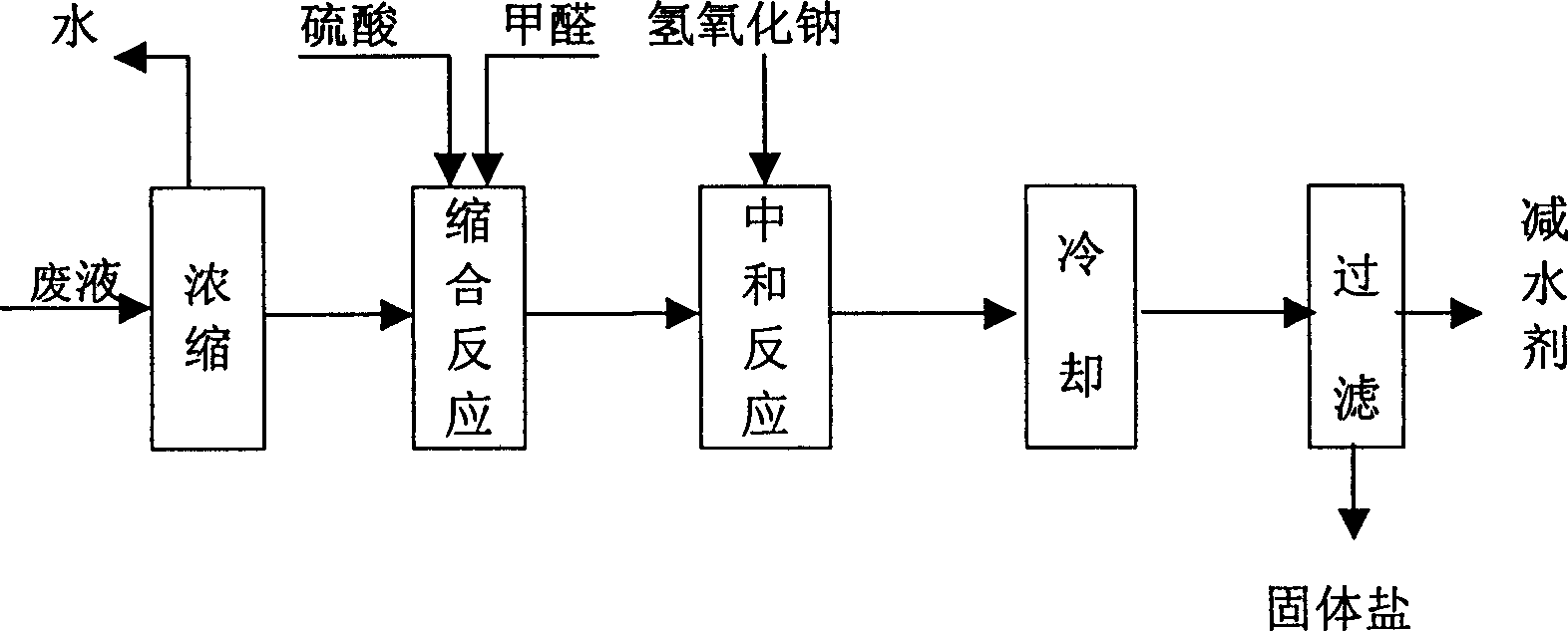

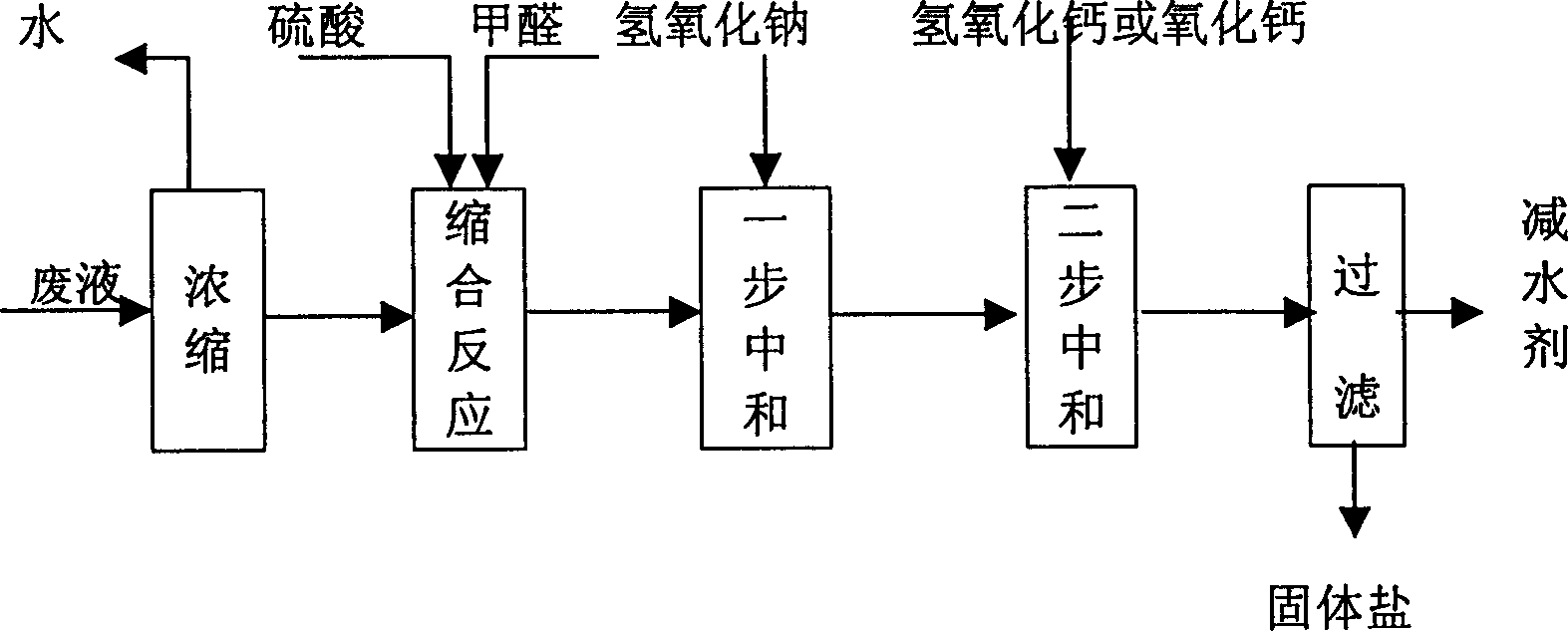

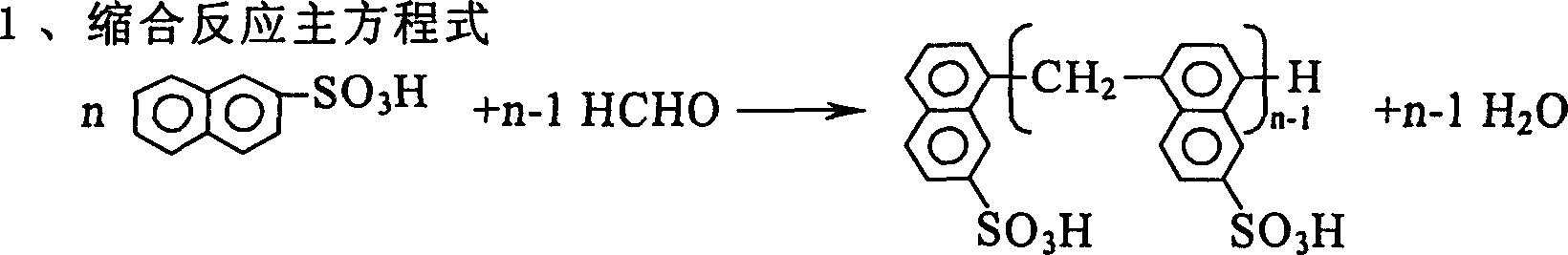

Method used

Image

Examples

Embodiment 1

[0032]Embodiment one: below is an embodiment of the present invention, has further described content of the invention of the present invention, and present embodiment is a kind of method that the pollutant that separates in " naphthalenesulfonic acid neutralizes washing waste liquid " reuses, First, 2000 grams of pollutants separated from the "naphthalenesulfonic acid neutralization washing waste liquid" are heated, evaporated and concentrated to 437 grams of "waste water concentrate" with a solid content of 59% by weight, and the "waste water concentrate" is placed in 2000ml In the four-necked round-bottomed flask, the oil bath is heated, and in the "wastewater concentrate", 196 grams of concentrated sulfuric acid with a weight concentration of 98% is added dropwise to adjust the total acidity to 27.5%. The amount of formaldehyde added dropwise is sulfonate group in the material. 0.8 times the number of moles is 45 grams. At a reaction temperature of 80°C and a relative pressu...

Embodiment 2

[0033] Embodiment 2: The following is another embodiment of the present invention, which continues to describe the content of the present invention. This embodiment is a method for reusing the pollutants separated from the "naphthalenesulfonic acid neutralization and washing waste liquid". Content is 30 kilograms of " waste water concentrated liquid " of 40% weight concentration, " waste water concentrated liquid " is placed in the reaction kettle, and in " waste water concentrated liquid ", dripping weight concentration is 15 kilograms of the concentrated sulfuric acid of 98%, total acidity Adjusted to 32%, the amount of formaldehyde added is 1.0 times the molar number of sulfonate radicals in the material to 4.2 kg, stirred at a reaction temperature of 150°C and a relative pressure of 0.4 MPa, and carried out a condensation reaction for 2 hours. After the condensation reaction was completed , cooled to 80°C, adding 40 kg of sodium hydroxide with a weight concentration of 30%...

Embodiment 3

[0034] Embodiment 3: The following is another embodiment of the present invention, which continues to describe the content of the present invention. This embodiment is a method for reusing the pollutants separated from the "naphthalenesulfonic acid neutralization and washing waste liquid" by adding naphthalenesulfonic acid and the mixture of methylnaphthalenesulfonic acid to obtain 30 kilograms of "wastewater concentrate" with a solid content of 70% weight concentration, "wastewater concentrate" is placed in the reactor, and the weight concentration is added dropwise in the "wastewater concentrate" Be 10 kilograms of the vitriol oil of 98%, total acidity is adjusted to 24%, the amount of adding formaldehyde is 1.0 times of sulfonate root molar number in the material is 4.2 kilograms, under the reaction temperature of 130 ℃ and 0.2 MPa relative pressure, stir , carry out the condensation reaction of 3 hours, after the condensation reaction is completed, cool to 80 ℃, add the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com