High-temperature burning joint production system for exhaused air from isolation room

A high-temperature combustion and scheduling system technology, applied in the direction of combustion method, combustion type, joint combustion mitigation, etc., can solve the problems of virus diffusion and transmission, and achieve the effects of reducing overall cost, simple structure, and simplified ventilation design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

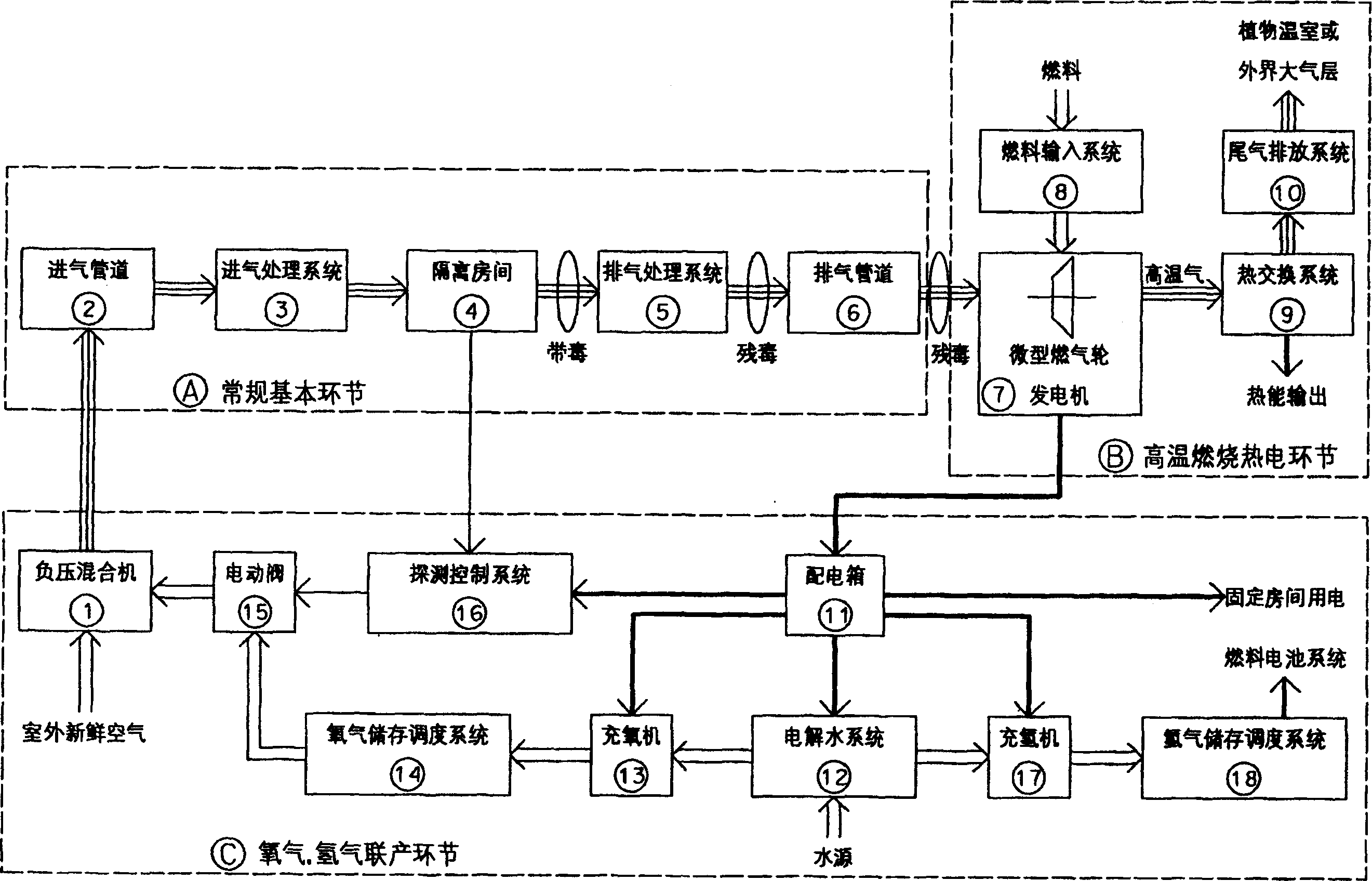

[0025] The composition of the high-temperature combustion cogeneration system of the isolation room exhaust of the present invention is as follows: figure 1 As shown, it consists of three parts: the first part A is the conventional basic link; the second part B is the high-temperature combustion thermoelectric link; the third part C is the oxygen and hydrogen cogeneration link.

[0026] 1. The part A in the figure is the routine basic link:

[0027] The intake pipe 2 is connected to the intake treatment system 3, the output of the intake treatment system 3 is connected to the isolation room (or room) 4, the output of the isolation room 4 is connected to the exhaust treatment system 5, and the output of the exhaust treatment system 5 is connected to the row Air pipe 6, exhaust pipe 6 communicate with the micro gas turbine generator 7 air inlet of B part.

[0028] 2. Part B in the figure is the high-temperature combustion thermoelectric link:

[0029] The exhaust pipe 6 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com