Process for recovering acrylic aldehyde or propionic aldehyde from low concentrate water solution flow

An acrolein, low-concentration technology, used in the separation/purification of carbonyl compounds, organic chemistry, etc., to achieve high total product recovery, low maintenance costs, and simple systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

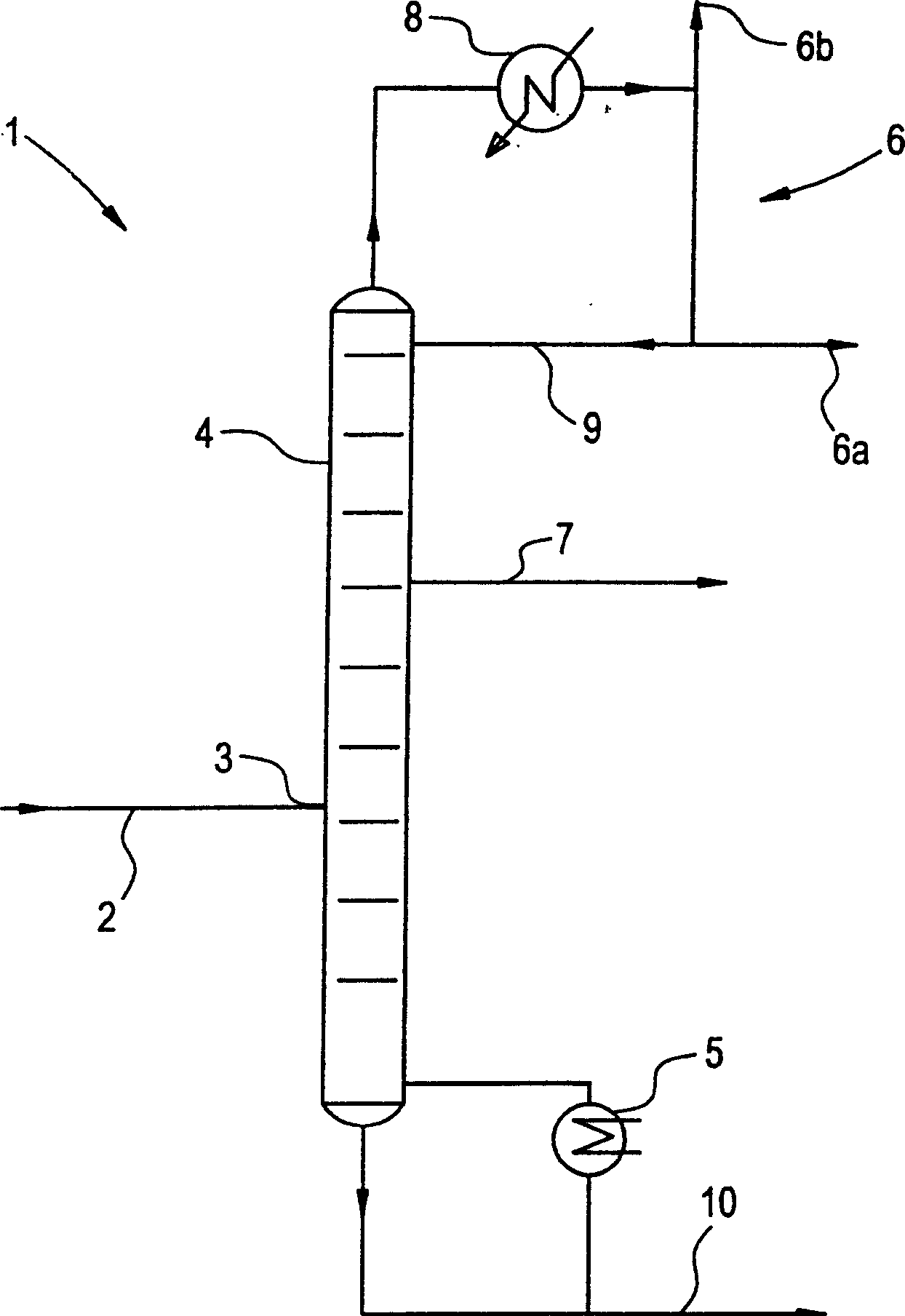

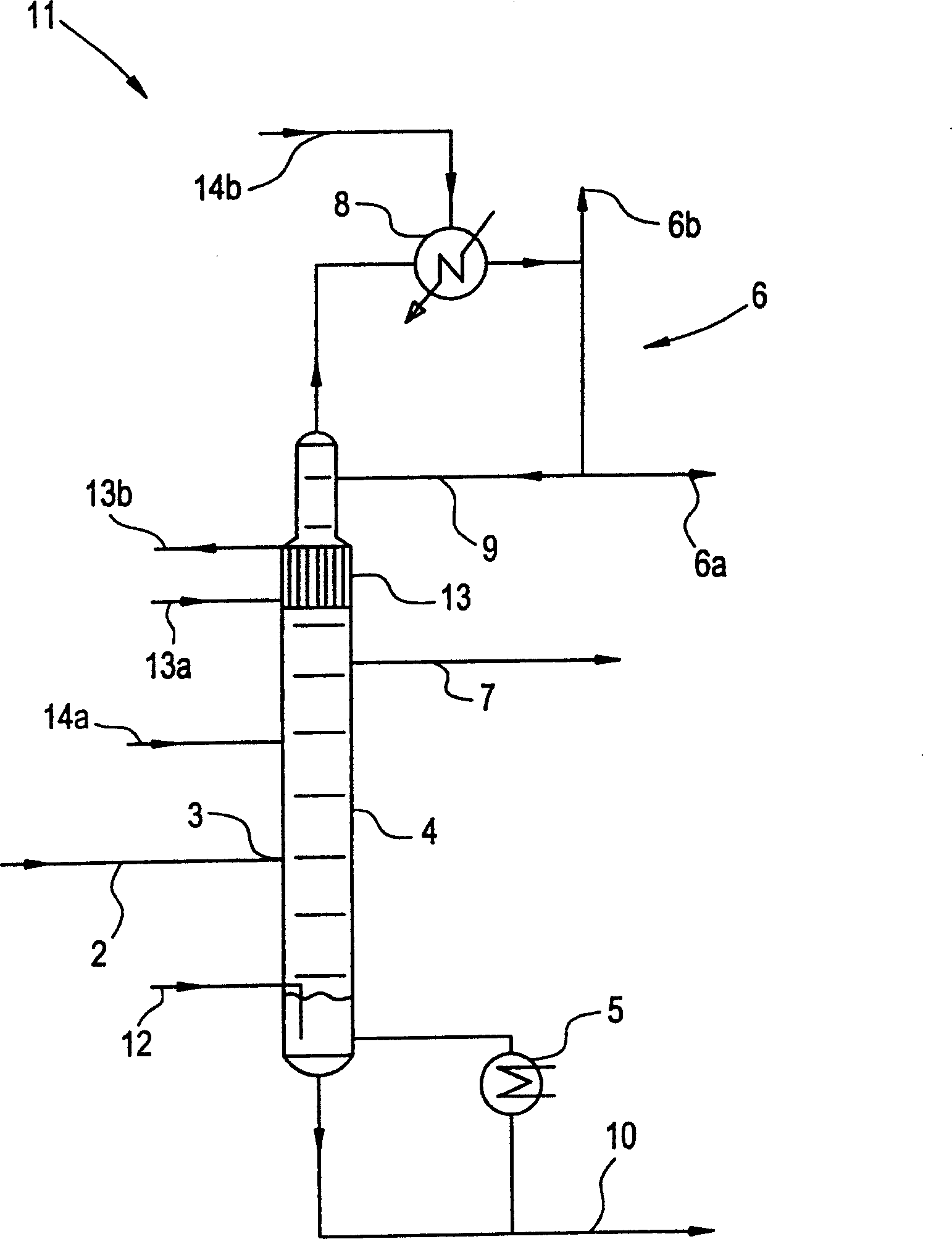

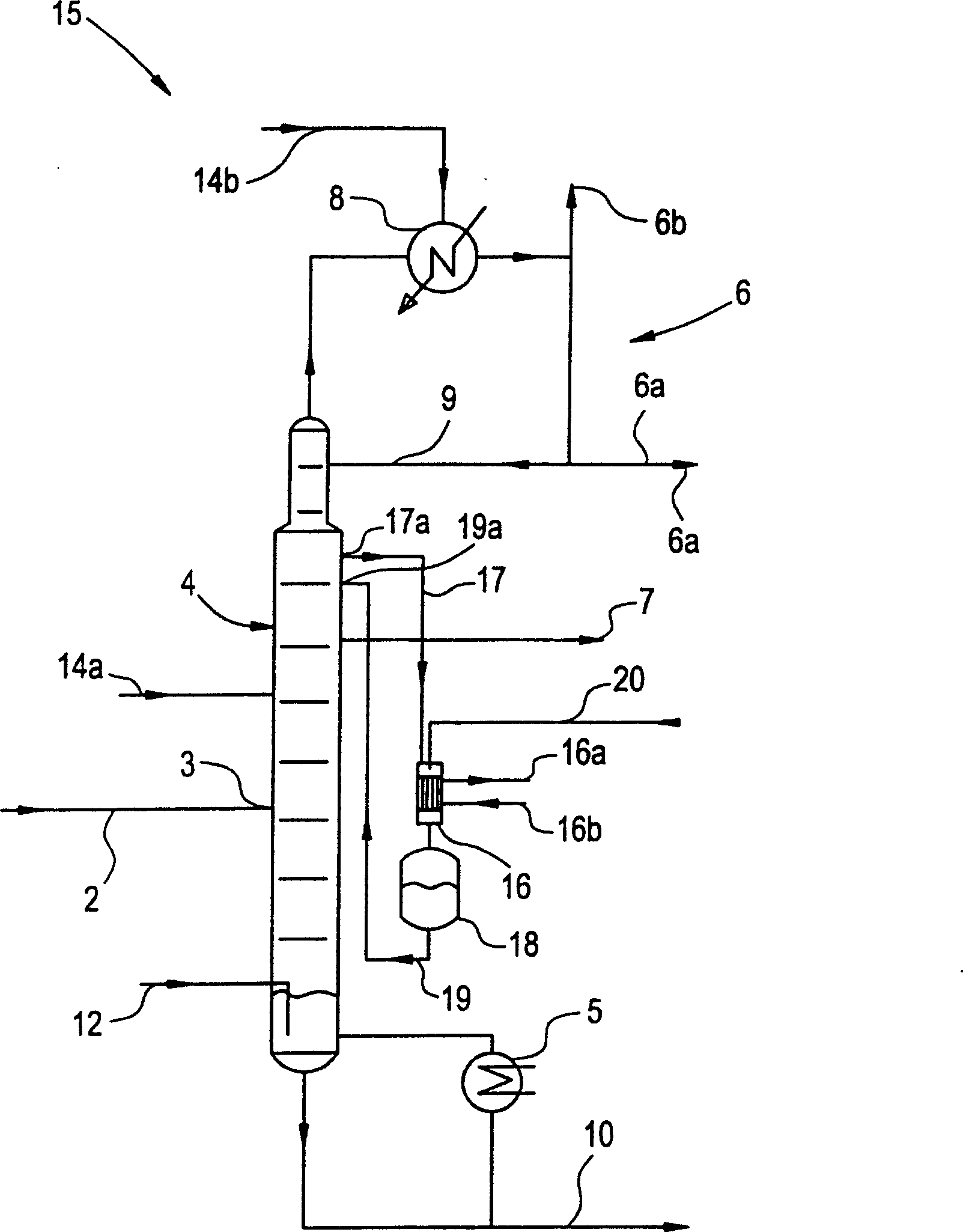

[0102] Examples 1-4: Laboratory scale distillation

[0103] Embodiment 1-4 uses figure 2The single-column distillation system shown is carried out, wherein, the stripping section: diameter 3gmm, 2 layers of Sulzer structure packing (equivalent to about 6 layers of theoretical trays), and 2 layers of sieve trays with downcomers below; Distillation section: 20 mm in diameter, 6 layers of Sulzer structure packing (equivalent to about 18 theoretical plates); light component removal section, 20 mm in diameter, 6 layers of Sulzer structure packing (equivalent to about 18 theoretical plates), in Above the side access port. The diameter of the water quenching cooling tower is 38mm.

[0104] The system is also equipped with auxiliary equipment for receiving fractions, sidedraw products and bottom discharges, sampling ports and post-processing equipment to avoid contact between operators and toxic substances.

[0105] The polymerization inhibitor solution used was hydroquinone (100 ...

Embodiment 5-7

[0109] Examples 5-7: Design of Simulation-Based Industrialization Process

[0110] In the following examples, a process model (computer model) of the acrolein purification process was established for use in the AspenPlus (version 10) process simulator. The model uses a non-random two-liquid (NRTL) liquid activity coefficient model to calculate the vapor-liquid equilibrium (VLE); NRTL parameters are compared to the mixture VLE data in the public literature and patent records for fitting. The model is used to calculate the design parameters and operating parameters of the distillation column for purifying and recovering acrolein.

[0111] The composition of the crude acrolein aqueous solution feed used in the following examples is shown in Table 2:

[0112] Feed composition

Embodiment 5

[0113] Embodiment 5: Utilize partial vacuum to improve the purity of acrolein product

[0114] Example 5a in Table 3 shows the simulation results for a side draw distillation column operated at atmospheric pressure; ie, the pressure in the condenser was 760 mmHg (absolute). In Example 5b in table 3, the same distillation column, fraction / feed ratio, reflux rate, acetaldehyde content in the acrolein side draw product, the difference is that the column operates under partial vacuum (condenser's The operating pressure is 490mmHg), and the temperature of each distillation section is correspondingly lower.

[0115] The simulation results show that the purification of acrolein can improve the purity and recovery rate when operating under vacuum compared with operating at or above atmospheric pressure.

[0116] Example 5a

[0117] other

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com