Spiral fractionation tower

A fractionation tower and spiral technology, applied in the field of oil separation equipment in the oil refining industry, can solve the problems of high cost, large investment, complex equipment, etc., and achieve the effect of low operating cost, low investment and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

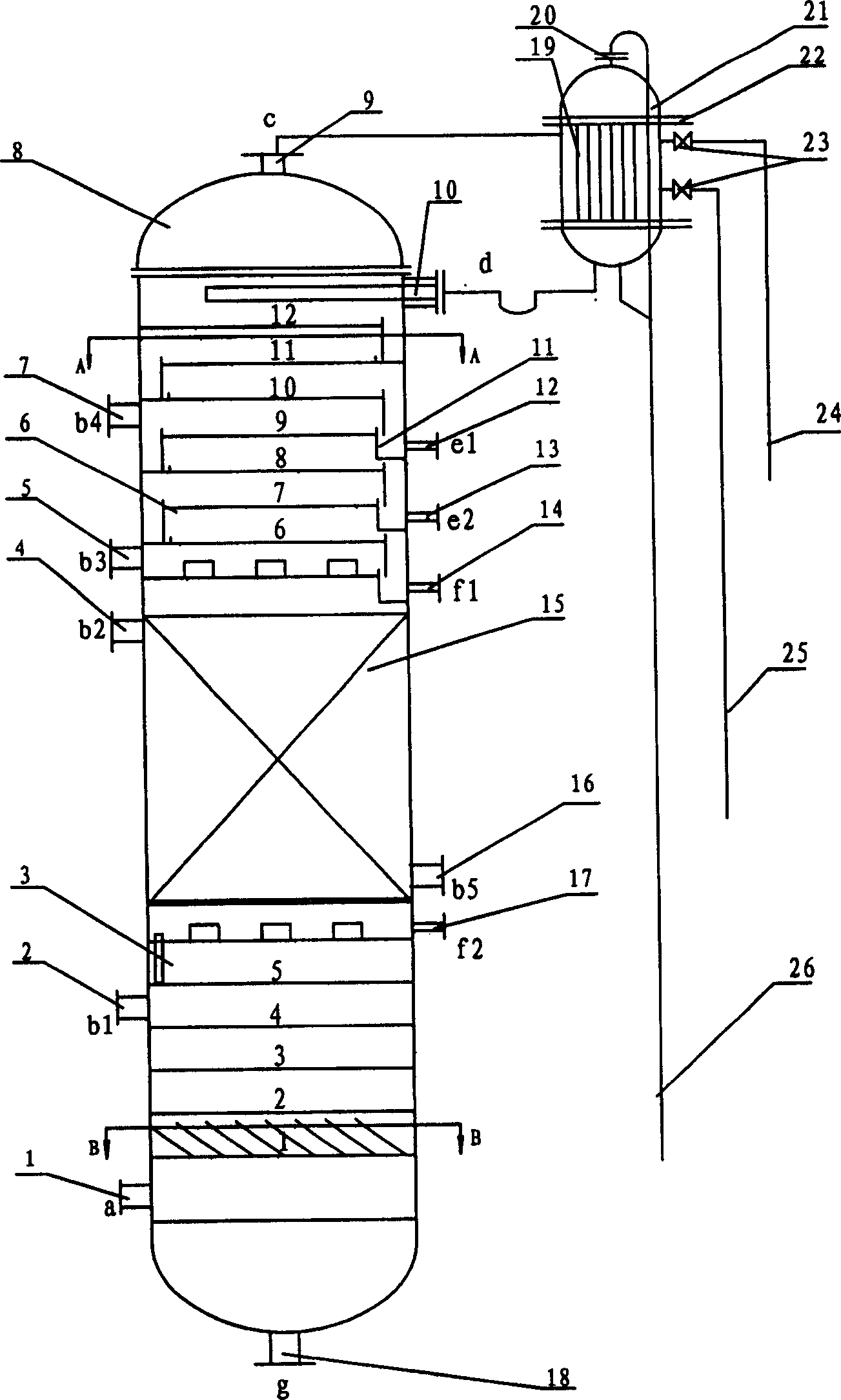

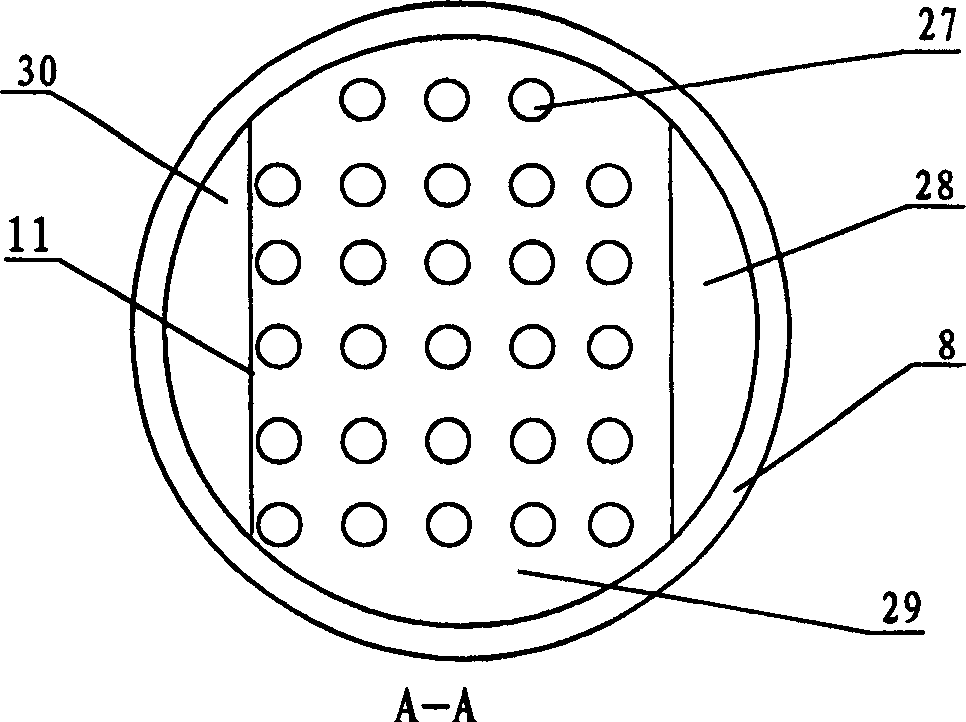

[0018] Below in conjunction with accompanying drawing, spiral fractionation tower of the present invention is described in further detail: as Figure 1-8 As shown, the interior of the spiral fractionation tower body 8 is divided into three sections, the tongue-shaped section is arranged as a tongue-shaped tray 3 in the lower part, and there are five layers of plate-shaped 1-5, and a plurality of tongue-shaped fins 31 are arranged at intervals on the upper part. One end of the fin 31 is fixed, and the other end is tilted to form a certain angle with the tongue-shaped tray 3, generally 20-60°, preferably 36° in the present invention, and the tongue-shaped tray 3 can be provided with multiple layers, preferably 5 layers. Each layer rotates at a certain angle relative to the next layer in parallel, generally 20-60°, preferably 36° in the present invention, 1-5 layers to 180° form a spiral channel, and the airflow rises 180° along the spiral channel. It is also possible to increase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com