Chemical raw material dispensing system

A chemical raw material and a new type of technology, applied in the direction of gaseous chemical plating, chemical instruments and methods, and from chemically reactive gases, etc., can solve the problems of increasing equipment operating liquidity, increasing equipment costs, multi-material bottles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

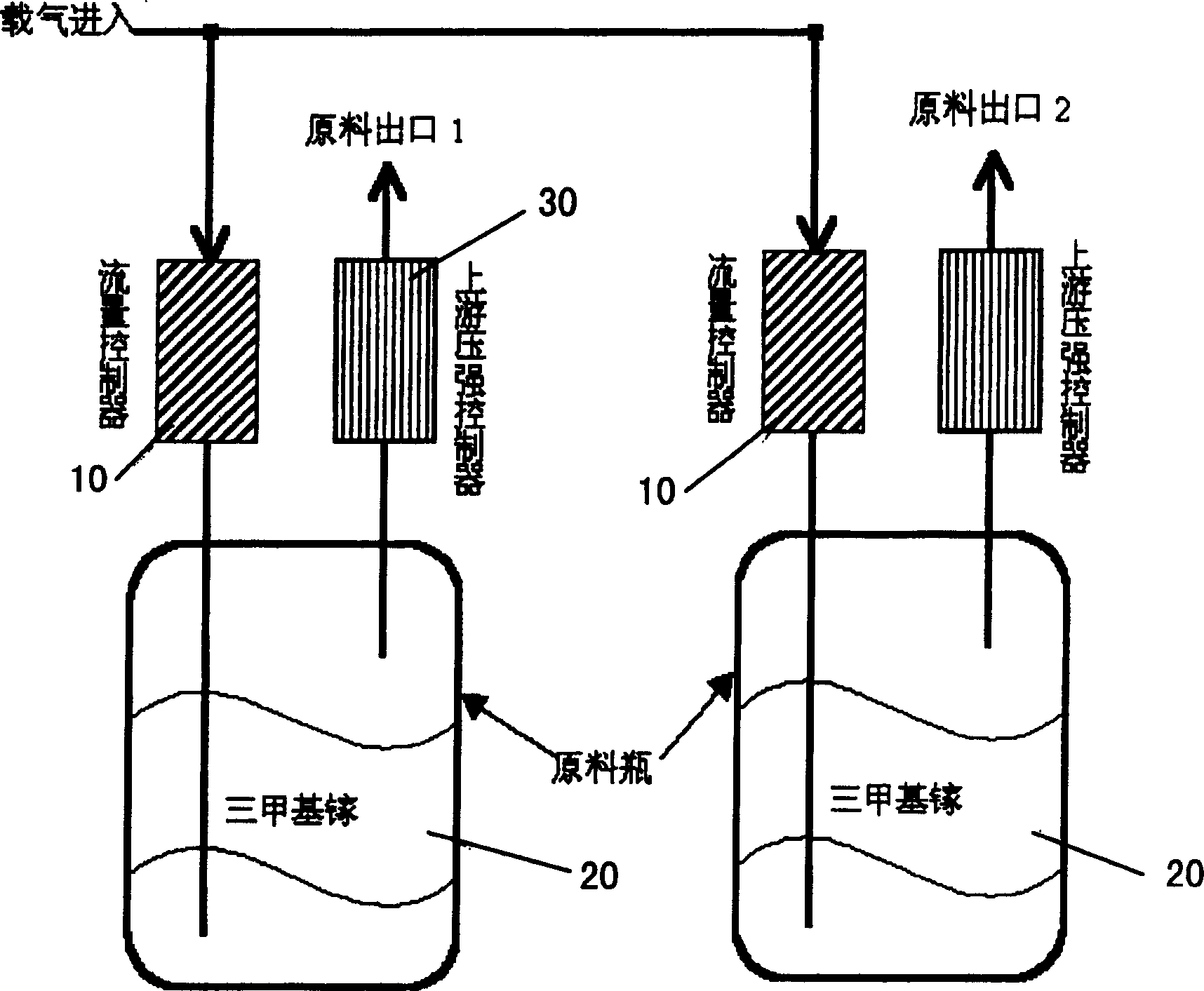

Embodiment 1

[0038] refer to image 3 (the same parts of the present invention use the same label), wherein the raw material bottles 20, 20' are more than two, each with a pressure controller 30 connected thereto, and the outlets of the raw material bottles 20 are respectively connected with more than two flow control devices. The flow controller 10 is connected to a material growth chamber 40 respectively. In a certain device, two channels of trimethylgallium and two channels of trimethylindium are required. Wherein trimethylgallium raw material bottle 20 (the connection relation of raw material bottle 20 and flow controller 10 and pressure controller 30 and figure 2 Similarly), a downstream pressure controller 30 is used to deliver the carrier gas (through the pipeline) to the raw material bottle to control the pressure in the raw material bottle 20 . In addition, the flow controller 10 is used to control the flow of the carrier gas output from the raw material bottle 20, and the two ...

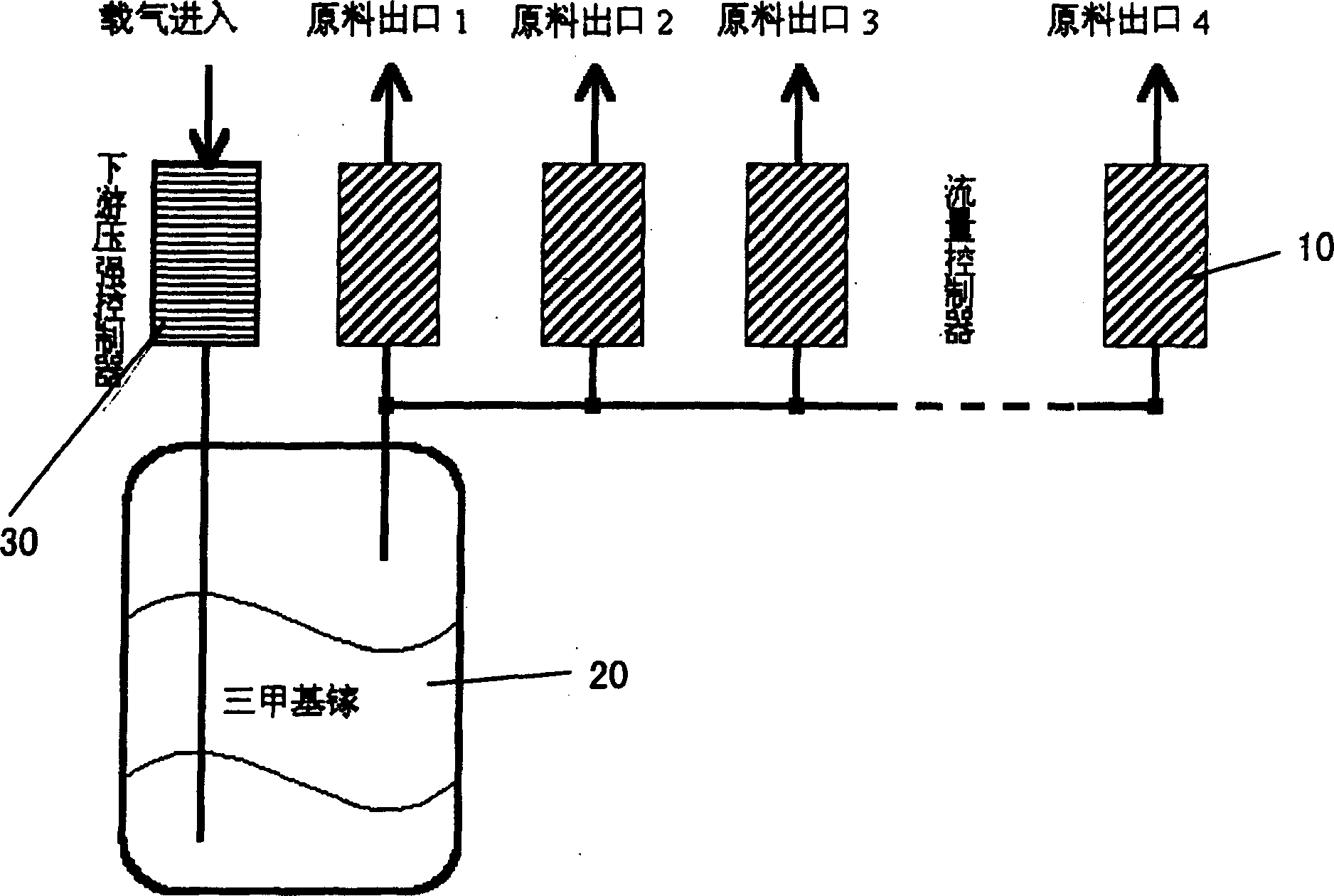

Embodiment 2

[0045] refer to Figure 4 , wherein there are more than two raw material bottles 20, 20', each having a pressure controller 30 connected thereto, and the outlets of the raw material bottles 20 are respectively connected with more than two flow controllers 10, and the flow controllers 10 are respectively connected to Enter more than two material growth chambers 40. In a certain semiconductor manufacturing equipment, there are two semiconductor material growth chambers 40 . Each growth chamber 40 requires one channel of trimethylgallium and one channel of trimethylindium. Among them, the trimethylgallium raw material bottle 20 uses a downstream pressure controller 30 (through a pipeline) to deliver carrier gas to the raw material bottle to control the pressure in the trimethylgallium raw material bottle 20 . In addition, the flow controller 10 is used to control the flow of the carrier gas output from the trimethylgallium raw material bottle 20, and the two flow controllers 10...

Embodiment 3

[0054] refer to Figure 5 , wherein the outlet of the raw material bottle 20 has a pressure gauge 50, and the pressure gauge 50 controls the flow rate of the flow controller 10. In a certain device, two channels of trimethylgallium are required. Use a flow controller (through the pipeline) to deliver the carrier gas to the trimethylgallium raw material bottle 20, and at the outlet side of the raw material bottle, use a pressure gauge 50 to measure the pressure in the raw material bottle. The pressure signal measured by the pressure gauge 50 is fed back to the flow controller 10. If the pressure in the raw material bottle is higher than a certain set value, the input of carrier gas to the raw material bottle is reduced or even stopped. If the pressure in the raw material bottle is lower than a certain set value, then increase the flow rate of carrier gas input into the raw material bottle. This controls the pressure in the raw material bottle. In addition, the flow controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com