Frequency conversion hydraulic well pumping unit for reducing installation power

A technology of installed power and pumping unit, which is applied in the field of frequency conversion hydraulic pumping unit, can solve the problems of not fully utilizing the efficiency of the motor and hydraulic pump, the motor cannot automatically adjust the output power, and the energy saving effect of the pumping unit is not obvious. Abundant software and hardware resources, remarkable energy-saving effect, and obvious energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

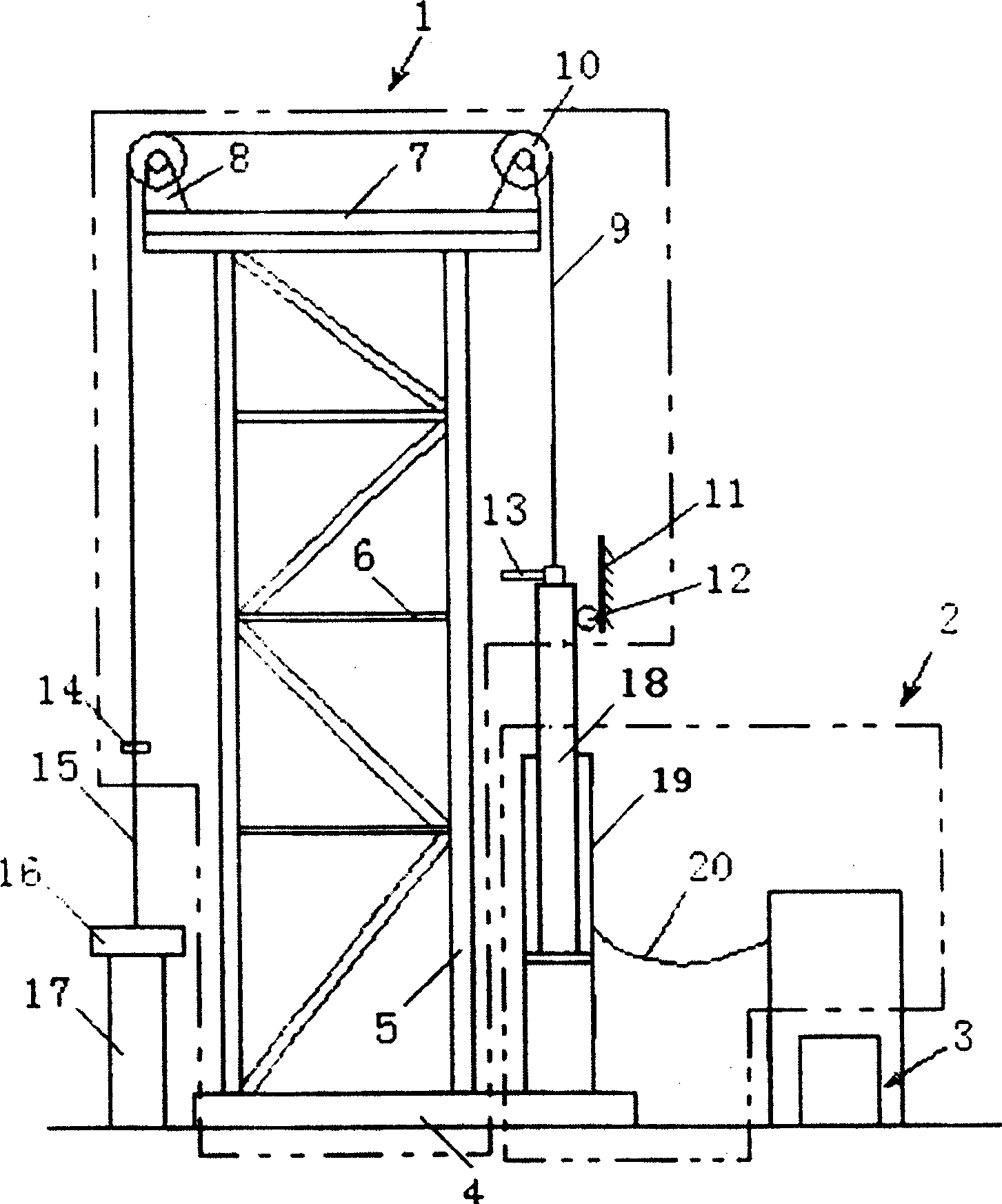

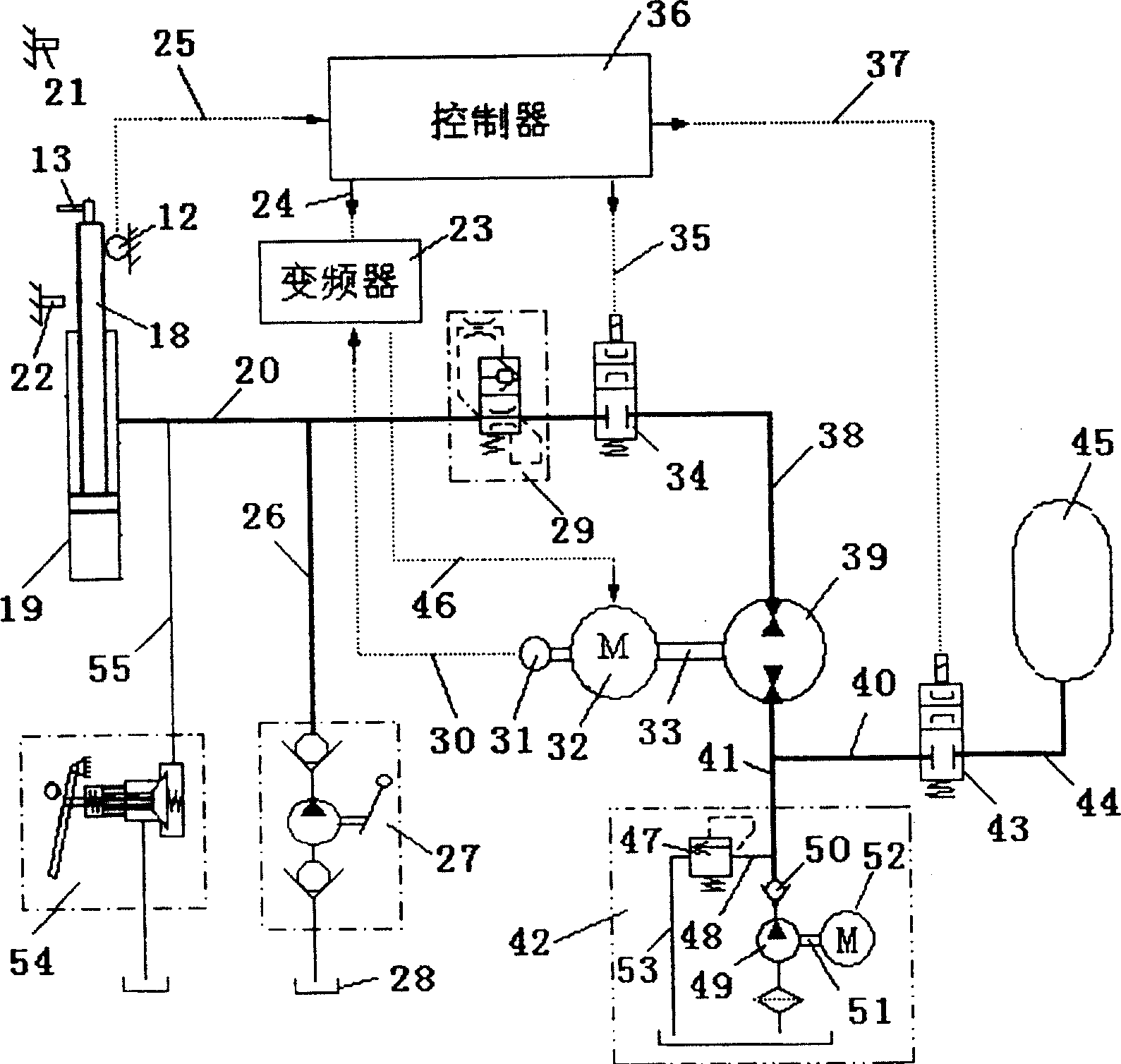

[0027] Depend on figure 1 and figure 2 It can be seen that the variable frequency hydraulic pumping unit is composed of a mechanical system 1, a hydraulic system 2, and a detection and control system 3, wherein:

[0028] 1) The mechanical system 1 includes: 4 bases, side brackets 5, base frame reinforcement ribs 6, upper base plate 7, roller brackets 8, steel wire ropes 9, rollers 10, guide rails 11, speed and position sensors 12, iron stops 13, rope hangers 14 , polished rod 15, christmas tree 16, tubing 17, plunger 18, hydraulic cylinder 19, pipeline 20; one end of the polished rod 15 of the pumping unit is connected to the oil pipe 17 through the christmas tree 16, and the steel wire rope at the other end of the polished rod 15 of the pumping unit passes through the roller 10 and The plunger 18 of the hydraulic cylinder 19 is connected, the side of the plunger 18 is equipped with a speed position sensor 12, and the top surface of the plunger 18 is equipped with a stopper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com