Roof thawing structure

A structure and roof technology, applied in building structure, roof, roof covering, etc., can solve problems such as ground subsidence, low thermal efficiency, unsatisfactory snow melting effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

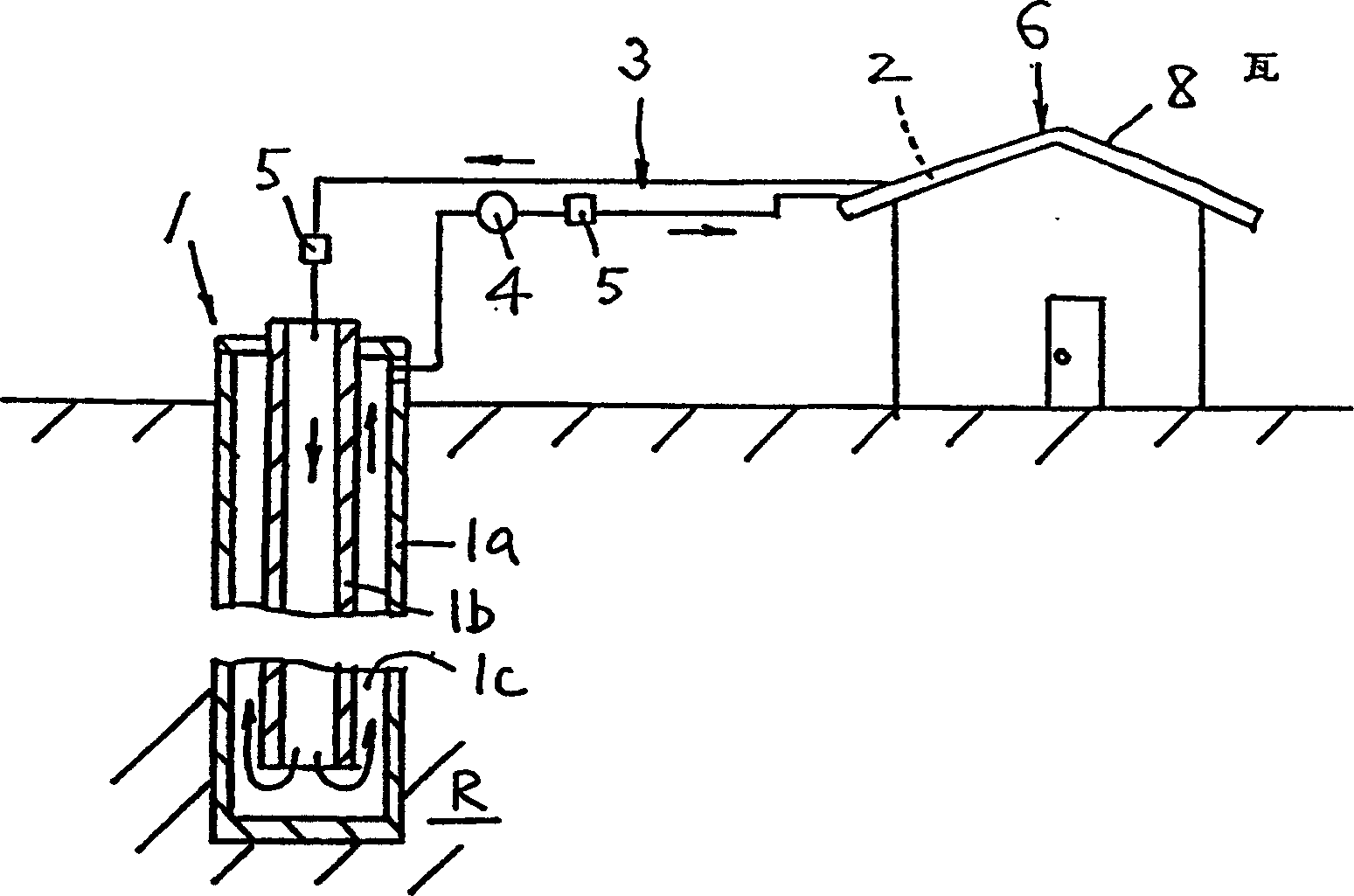

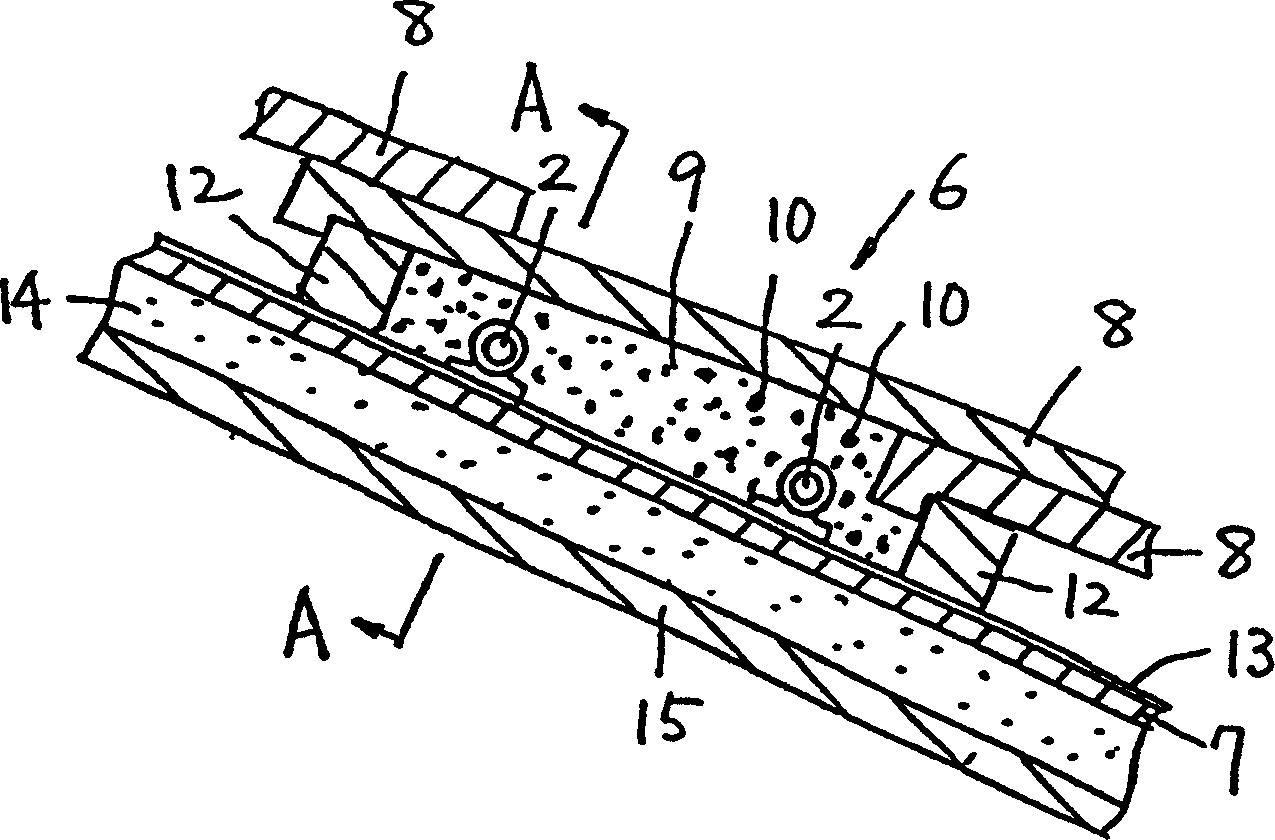

[0046] Regarding the embodiment of the first invention of the snow-melting roof structure, such as Figure 1 to Figure 4 shown. The structure of the snow-melting roof is to vertically bury the heat exchanger 1 that collects underground heat energy with antifreeze inside circulating in the ground, and transport the antifreeze liquid through the circulation pipe 3 to the heat radiation pipe 2 laid on the roof 6, and use the heat energy to melt the snow. Snow accumulation on roof 6.

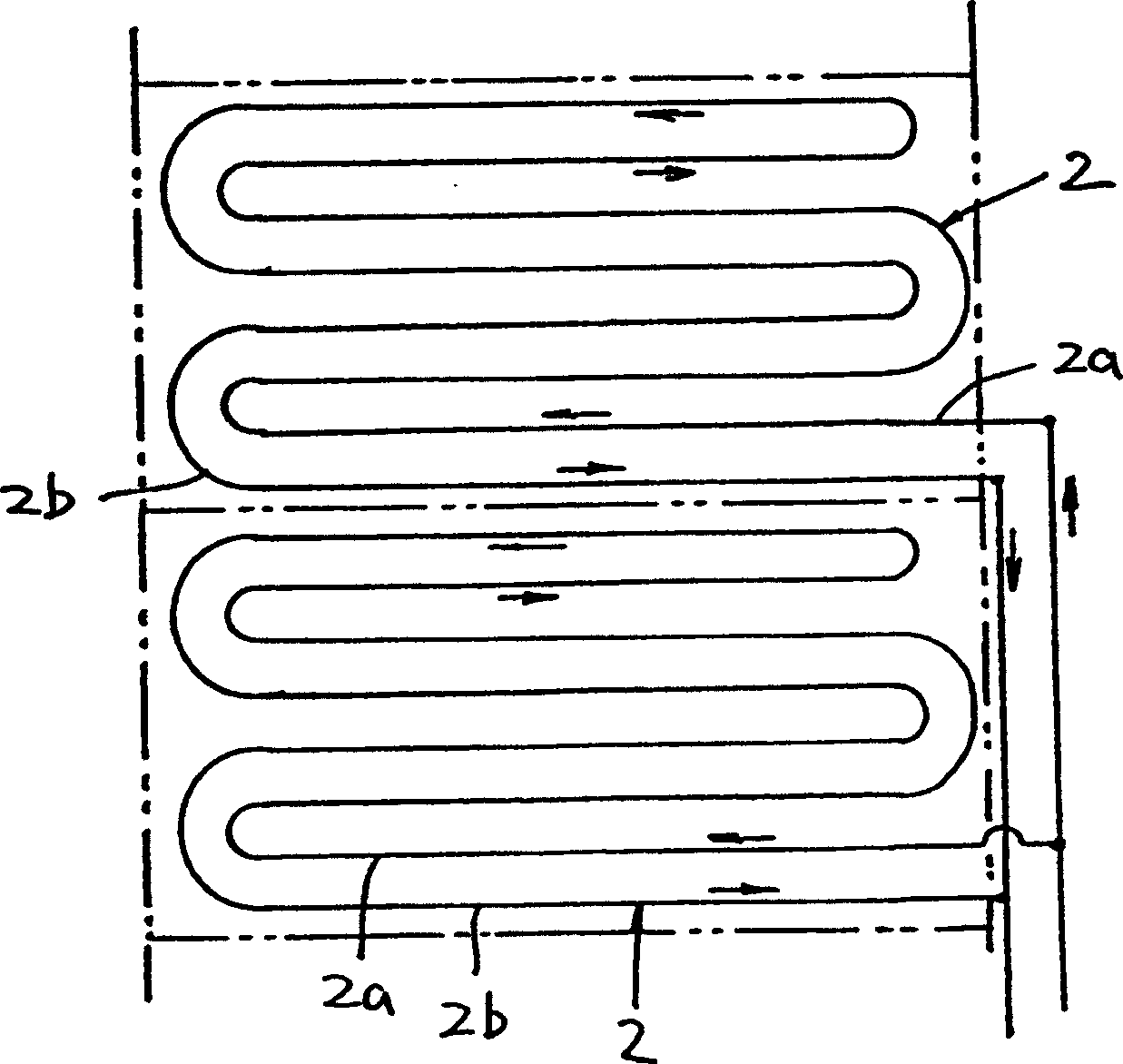

[0047] In this embodiment, the heat exchanger 1 is a concentric double pipe inserted into an inner cylinder 1b at the same center in an outer cylinder 1a with a closed lower end, and the lower end portion is buried in a rock layer R located 100m to 200m underground. And the heat release pipe 2 is formed by connecting the outgoing path 2a and the loop 2b end-to-end in the shape of a hairpin to ensure uniform heat dissipation throughout the whole length.

[0048] The above-mentioned heat radiation p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com