Trace oxygen controller for port wine

A control device and wine technology, applied in the preparation of alcoholic beverages, etc., can solve the problems of high dissolved oxygen content in wine, unfavorable wine ripening, wine replenishment, etc., and achieve effective dissolution, good diffusion effect, and small oxygen bubbles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

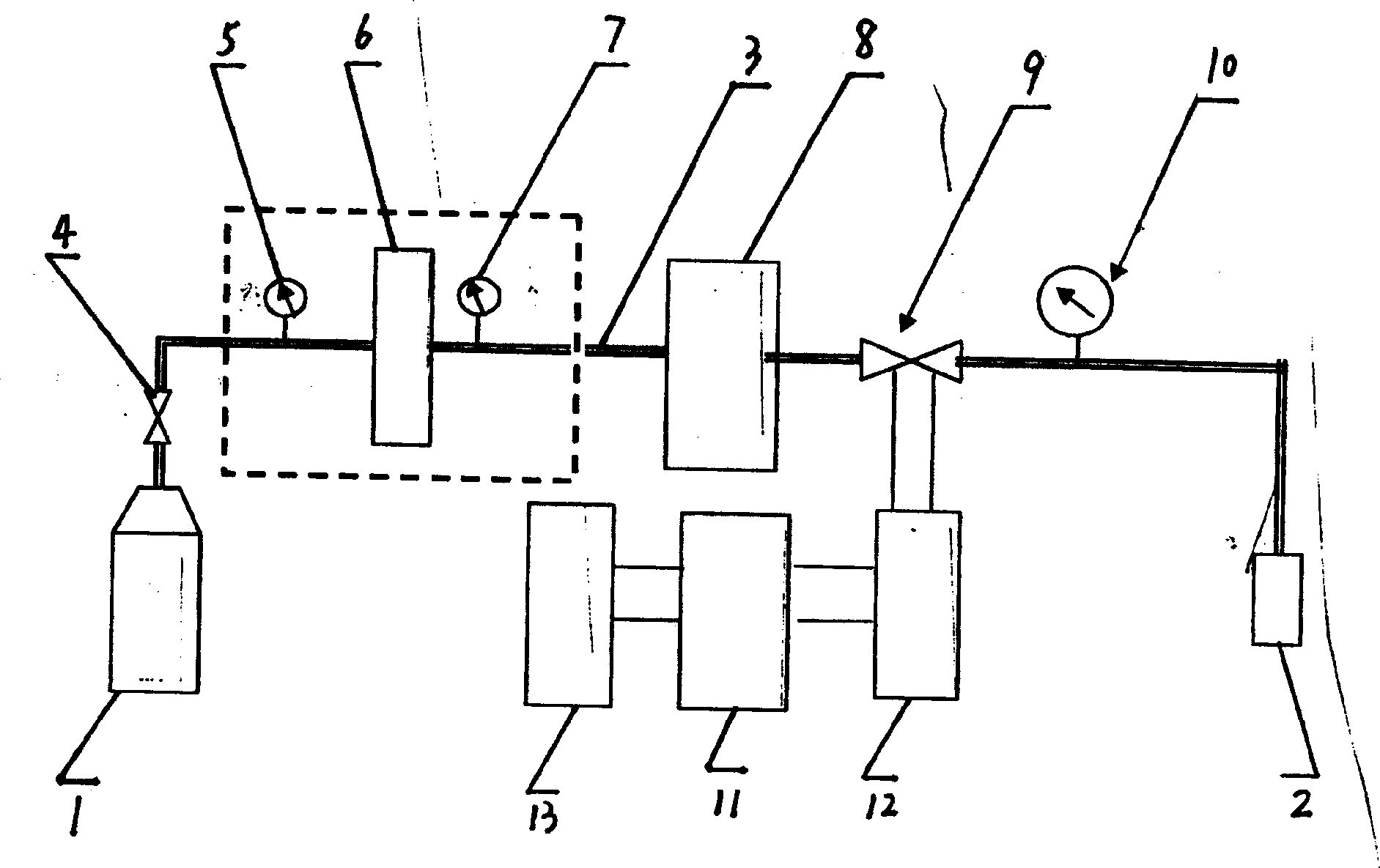

[0018] The present invention adjusts the content of dissolved oxygen in the wine in the large stainless steel container by adding trace oxygen for the first time, so as to maintain it at an appropriate level, so as to meet the needs of wine maturation for trace oxygen without causing its excessive The purpose of oxidation is to simulate the aging environment of wine in oak barrels. Referring to the accompanying drawings, including an oxygen cylinder 1, on the pipeline 3 formed by a connecting hose between the oxygen cylinder 1 and the diffuser 2, there are successively a main valve 4, an air inlet pressure gauge 5, an oxygen pressure reducing valve 6, Air outlet pressure gauge 7, pressure regulating valve 8, solenoid valve 9, pressure gauge 10, microcomputer timing switch 11 is connected with solenoid valve 9 by transformer 12, and power supply 13 is the power supply of microcomputer time control switch 11. The present invention adopts a two-stage decompression method to preci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com