Method for feeding closed liquid system

A liquid and material feeding technology, which is applied in the field of automatic feeding, can solve the problems of pressure drop, automatic cutting of equipment, etc., and achieve the effect of optimizing the starting pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

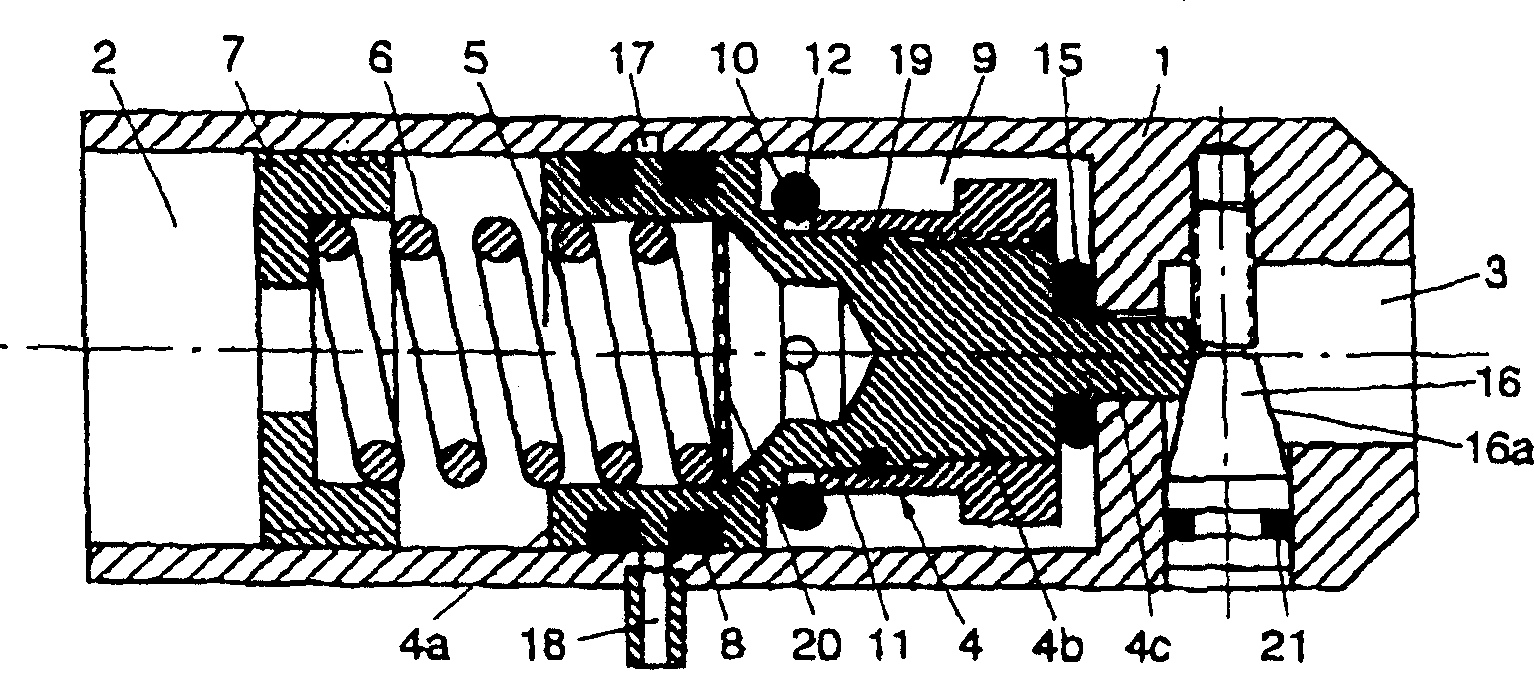

[0024] figure 1 The drip feeder shown in includes a cylindrical housing 1 with an inlet 2 and an outlet 3. A plunger 4 is slidably provided inside the housing 1, and the plunger 4 includes a first portion 4a, a second portion 4b and a pin-shaped protrusion 4c.

[0025] The first part 4a is internally provided with a cavity 5 for receiving and interposing a filter plate 20 supporting the end of a spring 6 otherwise supported on an annular stop 7 movably arranged in the housing 1 . The outer peripheral surface of the first part 4a moves in a sliding fit along the inner wall of the cylindrical housing 1, while the sealing ring 8 hermetically divides the space in the housing 1 into left and right sides of the first part.

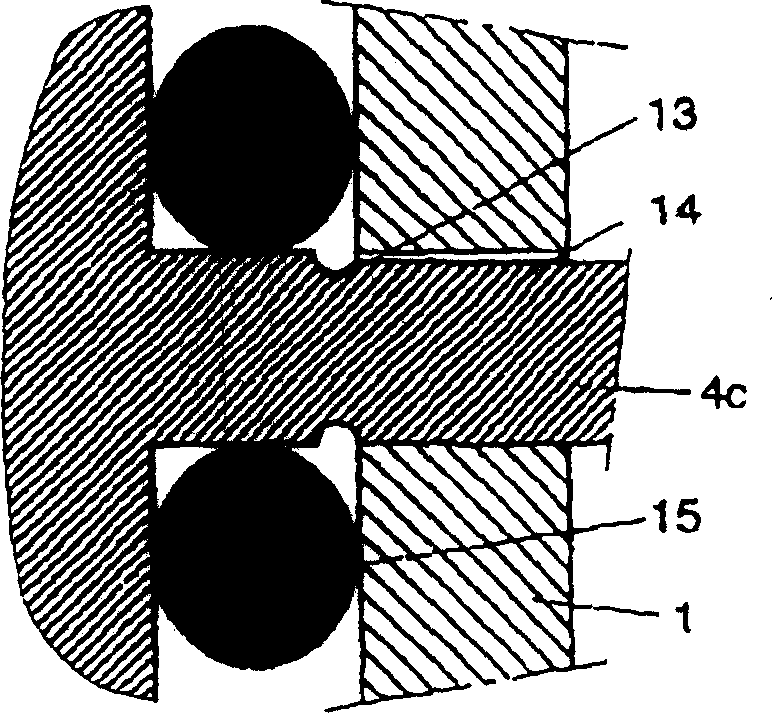

[0026] The diameter of the second part 4b of the plunger 4 is smaller than the diameter of the first part 4a, so that a space 9 is formed inside the housing 1 around the second part 4b. In the outer peripheral surface of the second part 4b is provided a groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com