Motor shaft for rotation/direct action converting motor and method of manufacturing the motor shaft

A technology of a motor shaft and a manufacturing method, which is applied in the field of rotary/direct conversion motors, can solve the problems of thread deviation, waste parts, and non-waste parts, etc., and achieves the effect of preventing position deviation and phase deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

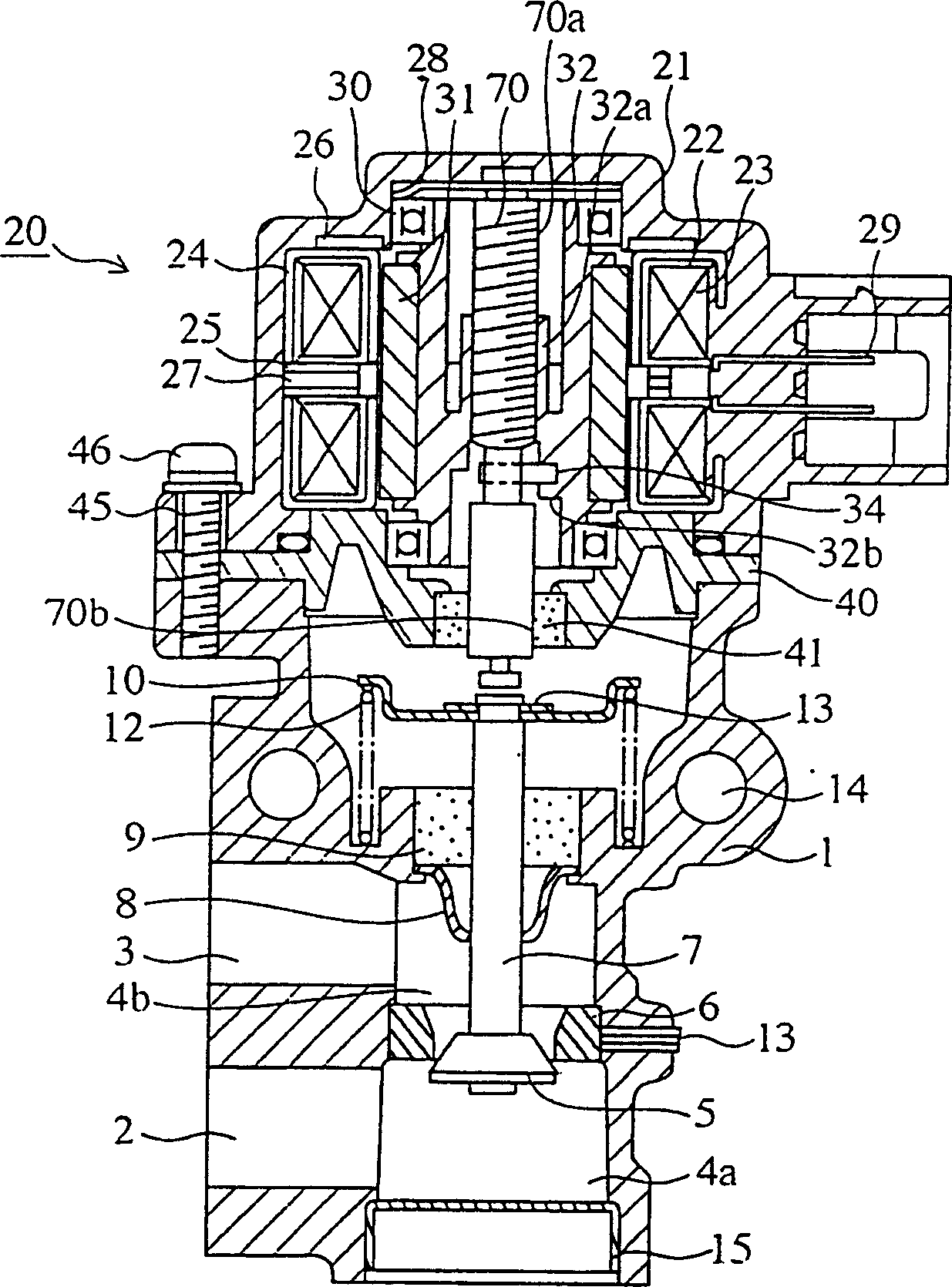

[0035] Hereinafter, in order to explain this invention in detail, the best form for carrying out this invention is demonstrated based on drawing.

[0036] Embodiment 1

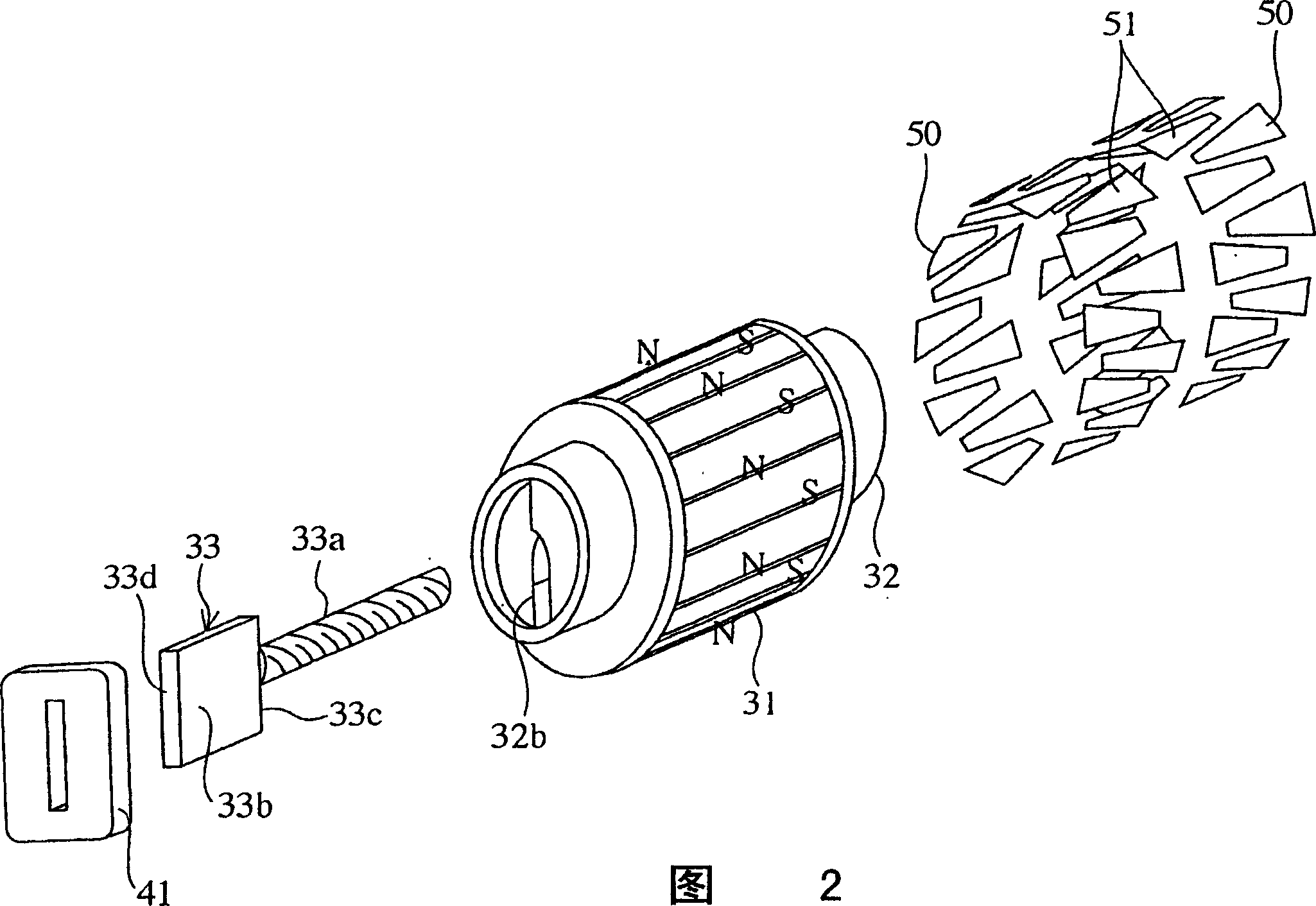

[0037] Fig. 2 is an exploded perspective view showing a main part of the rotary / linear conversion motor in the first embodiment.

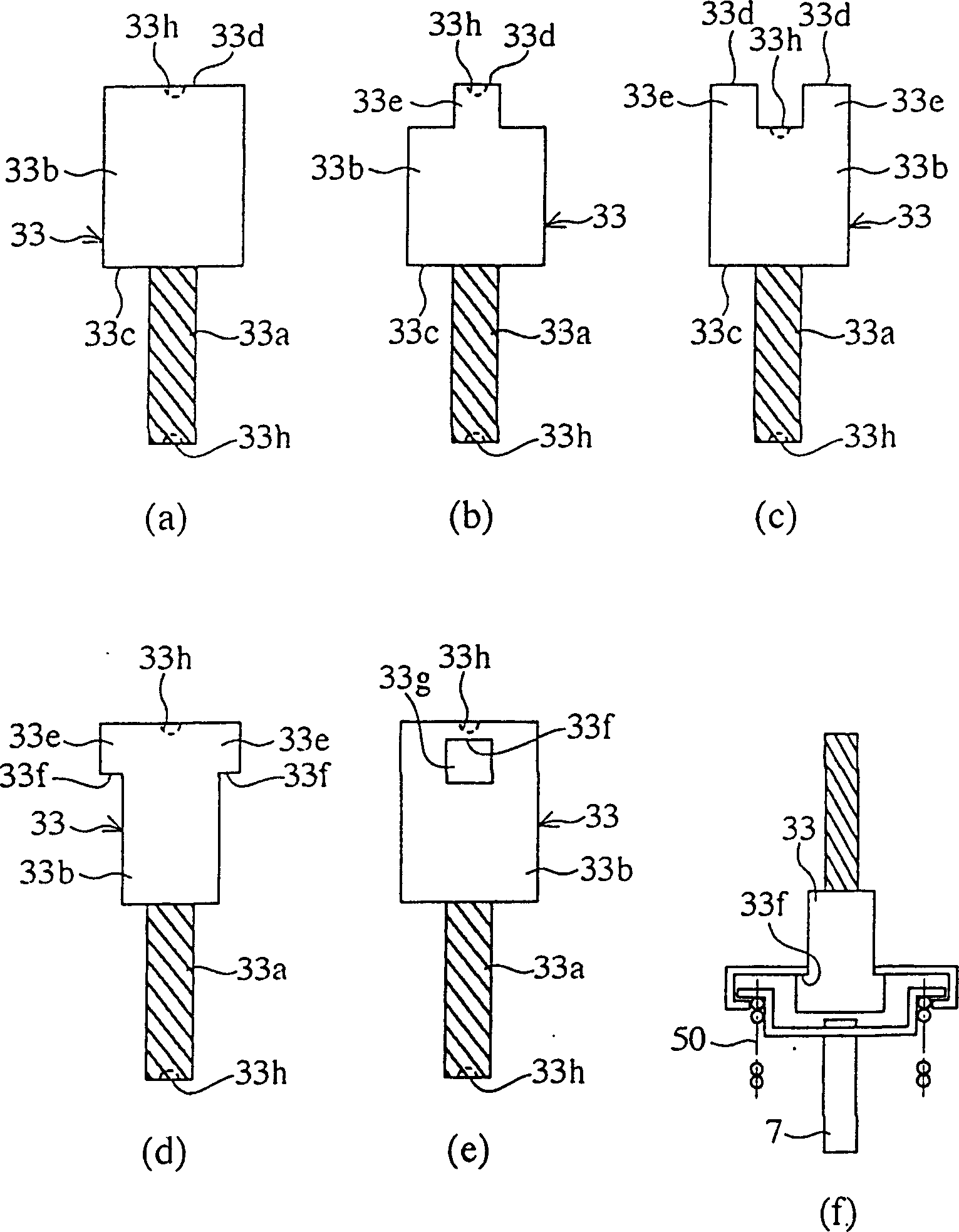

[0038] In this figure, 50 and 51 are stators such as iron cores wound with coils, 31 is a magnet composed of permanent magnets, etc., and 32 is a magnetic field generated by the flow of current in the stators 50 and 51. 32b is a stopper formed on the end surface of the rotor 32 on the valve shaft side to serve as a stopper on the motor side of the motor shaft 33 (described later). 33 is a motor shaft, which restricts the rotation of the motor shaft 33 in the direction of rotation around the shaft by engaging the threaded portion 33a with the rotor 32, engaging with the bushing 44 (described later), and a flat plate-shaped rotation restricting portion 33b; It is formed by the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com