Cell

A battery and power collection technology, applied in dry batteries, secondary batteries, lead-acid batteries, etc., can solve problems such as reducing battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

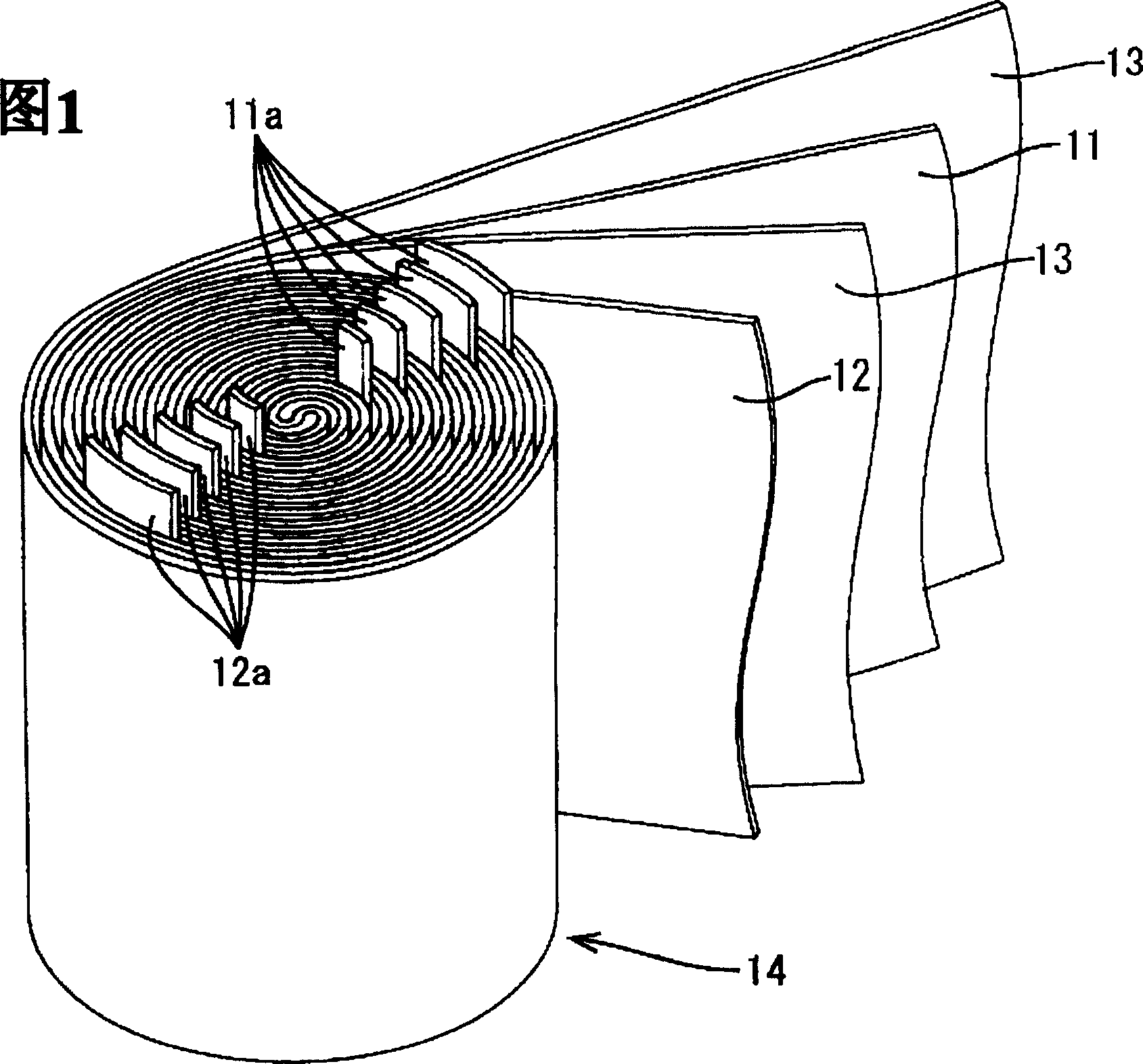

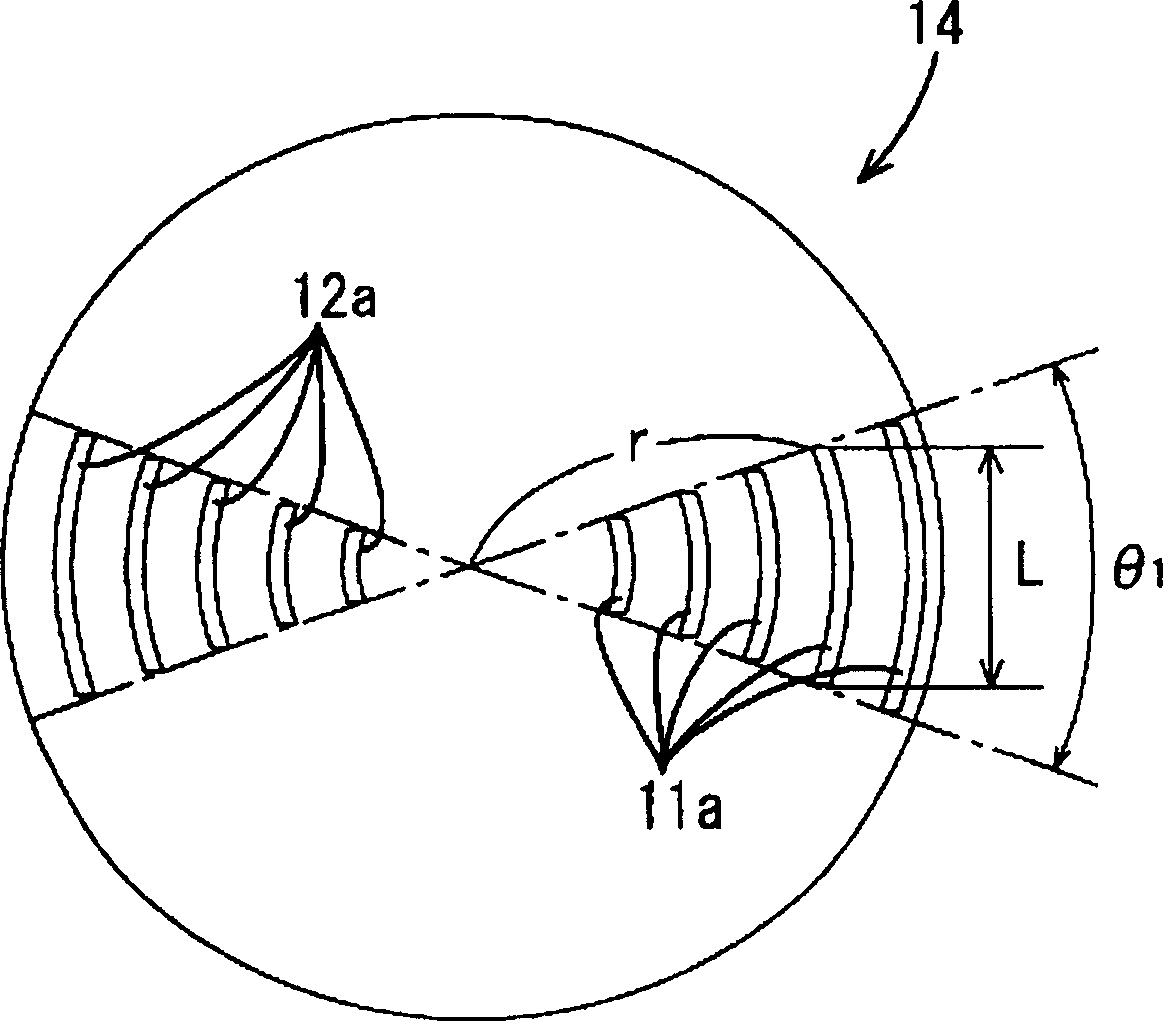

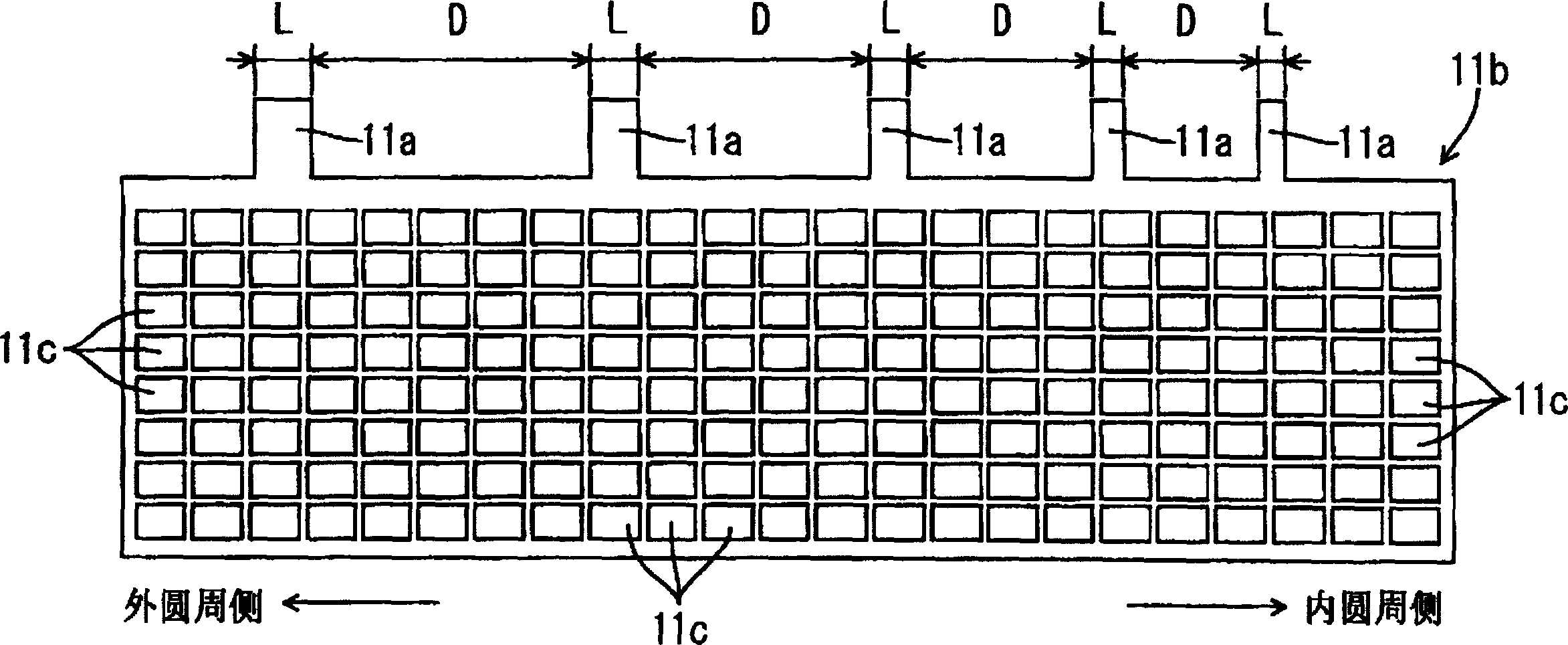

[0029] A cylindrical lead storage battery as an embodiment of the present invention will be explained below with reference to the accompanying drawings. The power generating element 14 of the lead storage battery is a cylindrical structure, which consists of the strip-shaped positive electrode 11 and the strip-shaped negative electrode 12 and the strip-shaped separator layer 13 are spirally wound together from the beginning to the end. As shown in FIG. 1, the coil-formed power generating element 14 has collector tabs 11a and 12a protruding from its upper portion, and is arranged along a straight line passing through the center of the coil. The current collector tab 11a of the positive electrode 11 is arranged in half of the straight line, that is, on one side of the winding center, while the current collector tab 12a of the negative electrode 12 is arranged in the other half. That is, the current collecting tabs 11a and 12a are arranged such that the current collecting tab on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com