Coproduction method of diammonium phosphate and monoammonium phosphate and equipment for neutralizing washing liquid

A technology of diammonium phosphate and monoammonium phosphate, which is applied in the direction of phosphate, phosphorus oxyacid, standpipe evaporator, etc., can solve the problems of reducing the capacity and life of phosphoric acid concentration equipment, affecting the stability of the production line, and high investment in production capacity. To achieve the effect of prolonging the life of the enrichment equipment, improving the capacity of the enrichment equipment, and reducing product costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

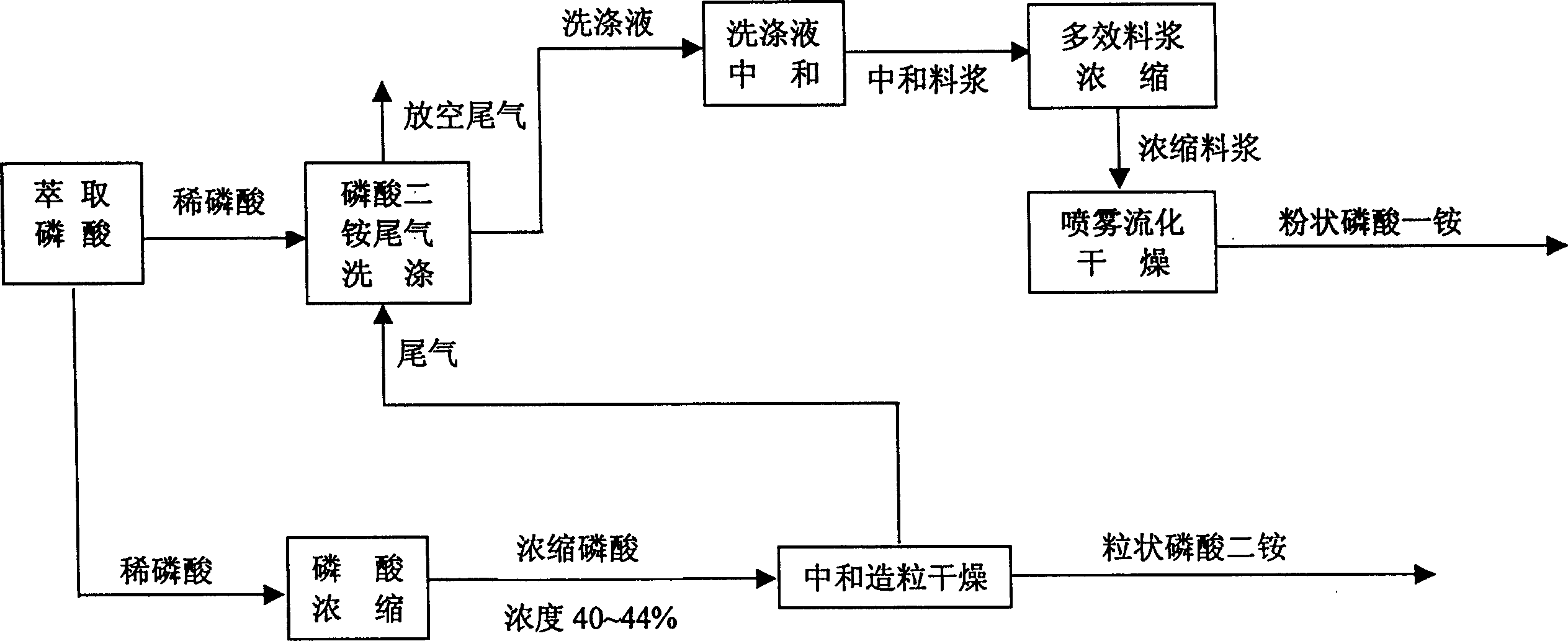

Embodiment 1

[0021] This example is the transformation of the imported diammonium phosphate production line. The production capacity of the original diammonium phosphate production line is 600,000 tons per year. After the transformation, the production capacity is 800,000 tons per year, of which 600,000 tons of granular / year, powdery monoammonium phosphate 200,000 tons / year. The modified process such as figure 1 As shown, the extracted phosphoric acid is 400,000 tons, 300,000 tons of which are produced by the "concentrated phosphoric acid method" of the original production line to produce diammonium phosphate, and 100,000 tons of which are used to wash the tail gas produced by the production of diammonium phosphate and wash with the tail gas The liquid is used as the raw material, and the powdery monoammonium phosphate is produced by the "neutralization slurry concentration method". The process steps of producing diammonium phosphate include phosphoric acid concentration, neutralization,...

Embodiment 2

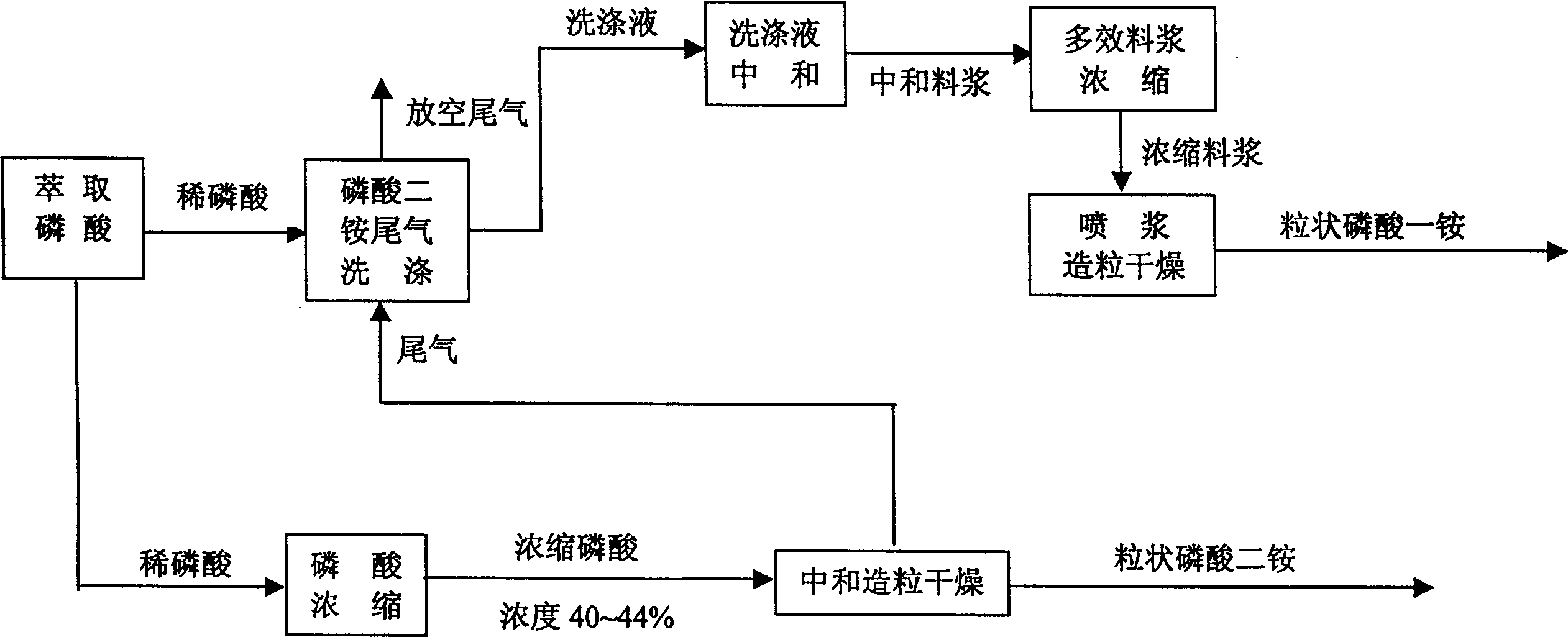

[0023] This embodiment is a newly-built diammonium phosphate and monoammonium phosphate co-production production line, and the technological process is as follows figure 2 shown. 80% of the extracted phosphoric acid is produced by "concentrated phosphoric acid method" to produce diammonium phosphate, and the rest is used to wash the tail gas produced by the production of diammonium phosphate, and the tail gas washing liquid is used as raw material to produce diammonium phosphate by "neutralization slurry concentration method" Monoammonium Phosphate Granular. The process steps of producing diammonium phosphate include concentration of phosphoric acid, neutralization and drying of raw materials in turn; concentration of phosphoric acid is to concentrate dilute phosphoric acid with a concentration of 25% to concentrated phosphoric acid with a concentration of 42%; the process parameters of neutralization, granulation and drying are: The pre-neutralization degree of the slurry i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com