Prepn of hard W-Co alloy

A cemented carbide, tungsten-cobalt technology, applied in the field of preparation of tungsten-cobalt cemented carbide, can solve the problems of low wear resistance, restricting the application of mining alloys, and limiting the scope of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

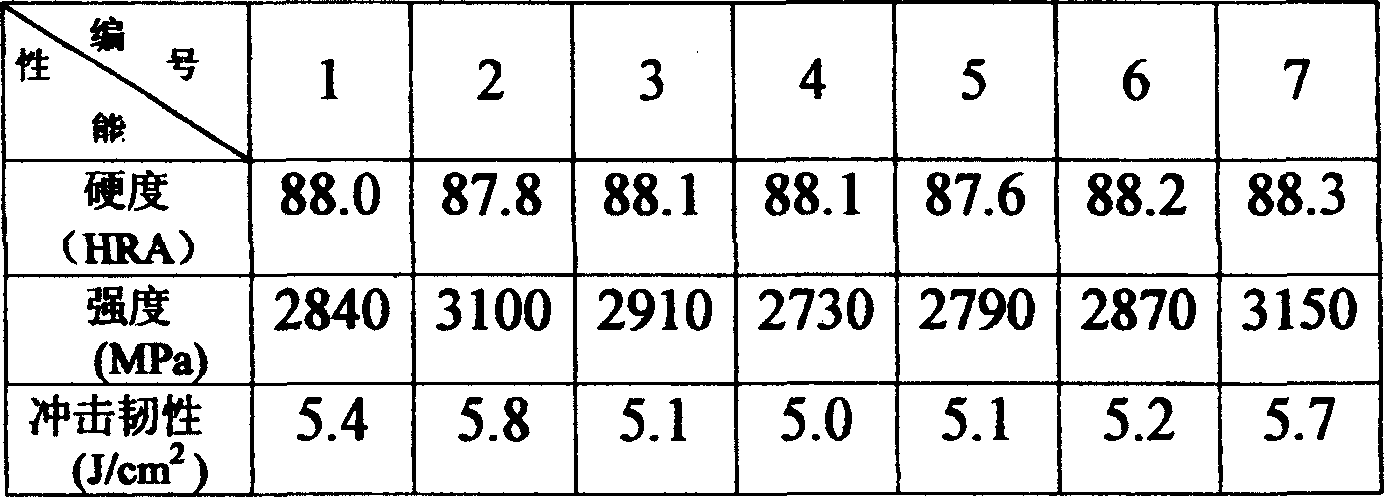

Examples

Embodiment 1

[0007] Example 1: Batch WC powder of two types of thickness and 9.5wt% Co powder according to certain requirements, unload after wet grinding for 20-23 hours, settle for 5-8 hours, dry and vibrate, granulate with forming agent, and press Forming, molding agent removal and sintering at 1450 ° C for 50 minutes to make cemented carbide. Among them, the particle size of coarse WC powder is 24.0 μm, the particle size of fine WC powder is 1.4 μm, the weight ratio of coarse WC powder and fine Co powder is 70:30, and the particle size of Co powder is 2.0 μm.

Embodiment 2

[0008] Example 2: Mix WC powder of two types of thickness and 10.0wt% Co powder according to certain requirements, unload after 20-23 hours of wet grinding, settle for 5-8 hours, dry and vibrate, mix with forming agent to granulate, and press Forming, molding agent removal and sintering at 1450 ° C for 50 minutes to make cemented carbide. Among them, the particle size of coarse WC powder is 28.4 μm, the particle size of fine WC powder is 1.8 μm, the weight ratio of coarse WC powder and fine WC powder is 70:30, and the particle size of Co powder is 1.0 μm.

Embodiment 3

[0009] Example 3: Mix two types of WC powder and 9.0wt% Co powder according to certain requirements, unload after 20-23 hours of wet grinding, settle for 5-8 hours, dry and vibrate, mix with forming agent to granulate, and press Forming, molding agent removal and sintering at 1450 ° C for 50 minutes to make cemented carbide. Among them, the particle size of coarse WC powder is 20.0 μm, the particle size of fine WC powder is 1.2 μm, the weight ratio of coarse WC powder and fine WC powder is 70:30, and the particle size of Co powder is 1.5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com