Technique for producing laser welding stainless steel tubes cladded optic fiber unit

A stainless steel tube, laser welding technology, applied in laser welding equipment, welding equipment, manufacturing tools and other directions, can solve the problems of unreasonable distribution of optical fibers, uneven distribution of optical fibers, and the effective life of optical fibers cannot be guaranteed. Good consistency, uniform and stable excess length, and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

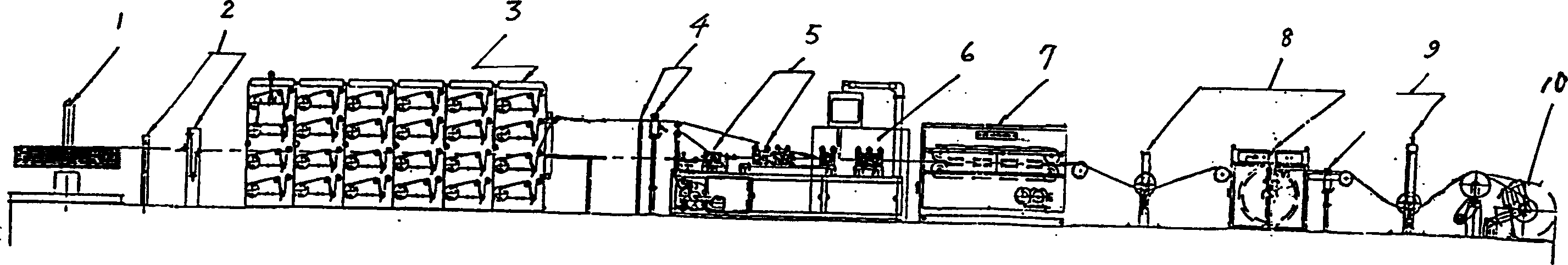

[0028] Refer to attached figure 1 , Laser welding stainless steel tube optical fiber unit production line Laser welding stainless steel tube optical fiber unit production line includes large-length optical fiber pay-off frame 3, oil-filled part 4, steel belt unwinding part, steel belt longitudinal wrapping and welding part 5, steel pipe drawing, on-line Weld seam detection part 6, traction and excess length control device 7, wire take-up device.

[0029] The large-length optical fiber pay-off stand 3 has a pay-off stand body, and several groups of single-disc fiber pay-off trays are arranged on both sides of the pay-off stand body, and a fiber guide slide bar is arranged beside the single-disk fiber pay-off tray. The disk is installed on the fiber optic disk shaft, the fiber optic disk shaft is installed on the double support bearing, and the fiber optic disk shaft end is equipped with a tension adjustable controller. The adjustable tension controller adopts a magnetic damper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com