Downward type back light module

A backlight module, direct-type technology, applied in optics, nonlinear optics, mirrors, etc., can solve the problems of yellowing of the screen, increased thickness, and short service life of printing inks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

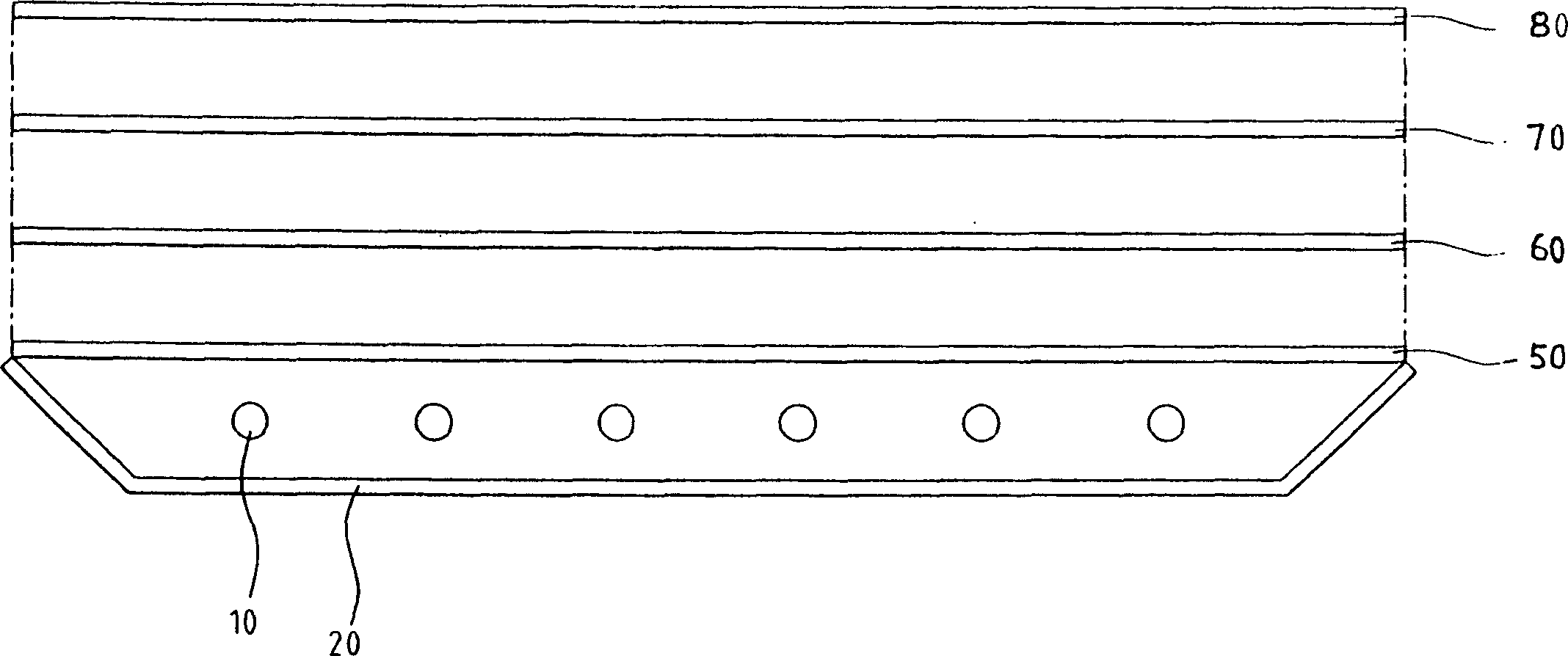

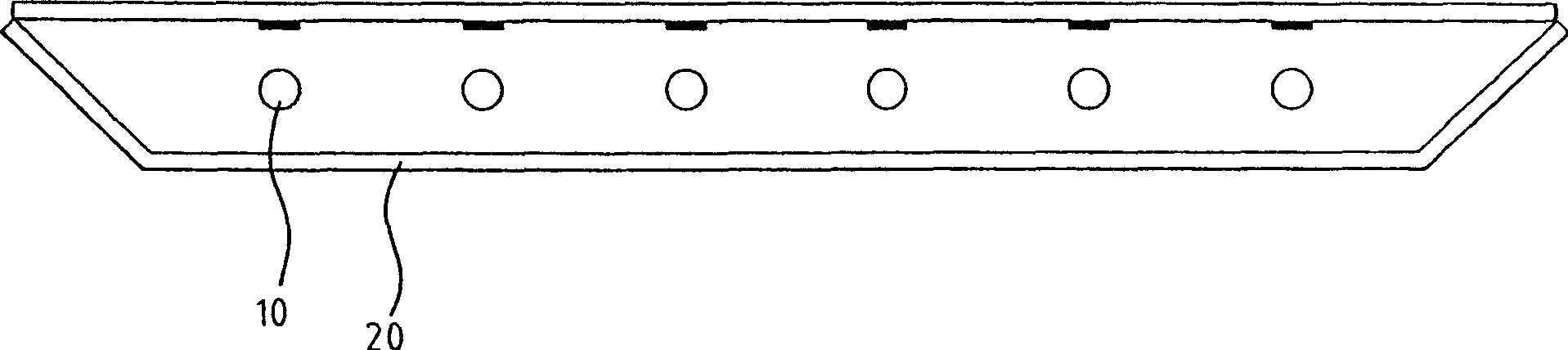

[0029] Such as Figure 4 As shown, the light source 240 is placed above the reflecting plate 250. The light source 240 is a lamp tube 240 with a diameter Φ of about 2.6 millimeters (mm) and is located in the slightly arc-shaped reflecting groove of the reflecting plate 250. It can be seen from the figure that the reflective groove surrounds the light source 240 half-circumferentially, and the central part of the reflective groove has a first reflective surface 210 that protrudes upward in an arc shape, and its radius of curvature is about 1 / 2 of the diameter of the light source 240. 2 to 3 times; the edge portion of the left side of the reflective groove has a second reflective surface 220, the inclination angle is about 20 degrees to 40 degrees, preferably 30 degrees; and the third reflective surface 230, its The inclination angle is about 40°-70°, preferably 60°, and the right side also has the same symmetrical structure. in addition, Figure 4 h in 1 Represents the dista...

no. 2 example

[0035] see Figure 7 , the initial structure and correlation coefficient are as follows Figure 4 and Figure 5 As shown, but in Embodiment 2, a non-printed light guide plate 260 is installed on the light source 240 to replace the existing diffuser plate. The radius of curvature of the light guide plate 260 is R 2 , where R 2 R 1 , in this embodiment, the material of the non-printed light guide plate 260 is a transparent acrylic material, which has a slightly arc-shaped light-transmitting groove on the side facing the light source 240, which is used to radiate light toward the light source 240. The position of the light transmission groove corresponds to the reflection groove of the reflection plate 250 , and the combination of the two can cover the light source 240 therein. In addition, the light guide plate 260 has a plurality of protrusions 270 at the connecting portion between the light-transmitting groove and the light-transmitting groove to reflect part of the refra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com