Sealing ring for stuffing box

A technology for stuffing boxes and diesel engines, which is applied in sealing, engine sealing, closing, etc. It can solve the problems of loss of lubricating oil, brushing, and reduced sealing efficiency, and achieve the effects of improving efficiency, reducing the number, and greatly adapting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

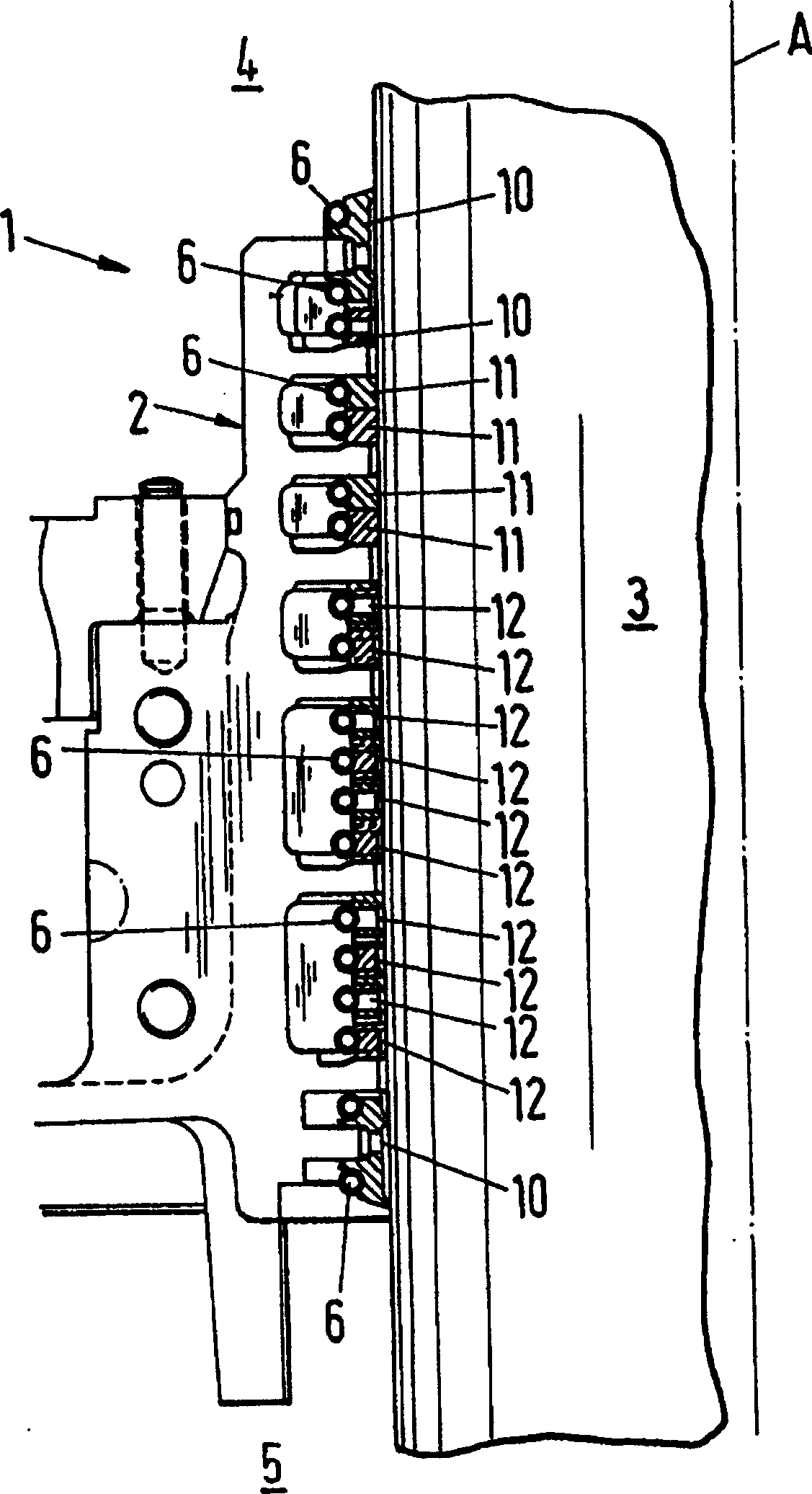

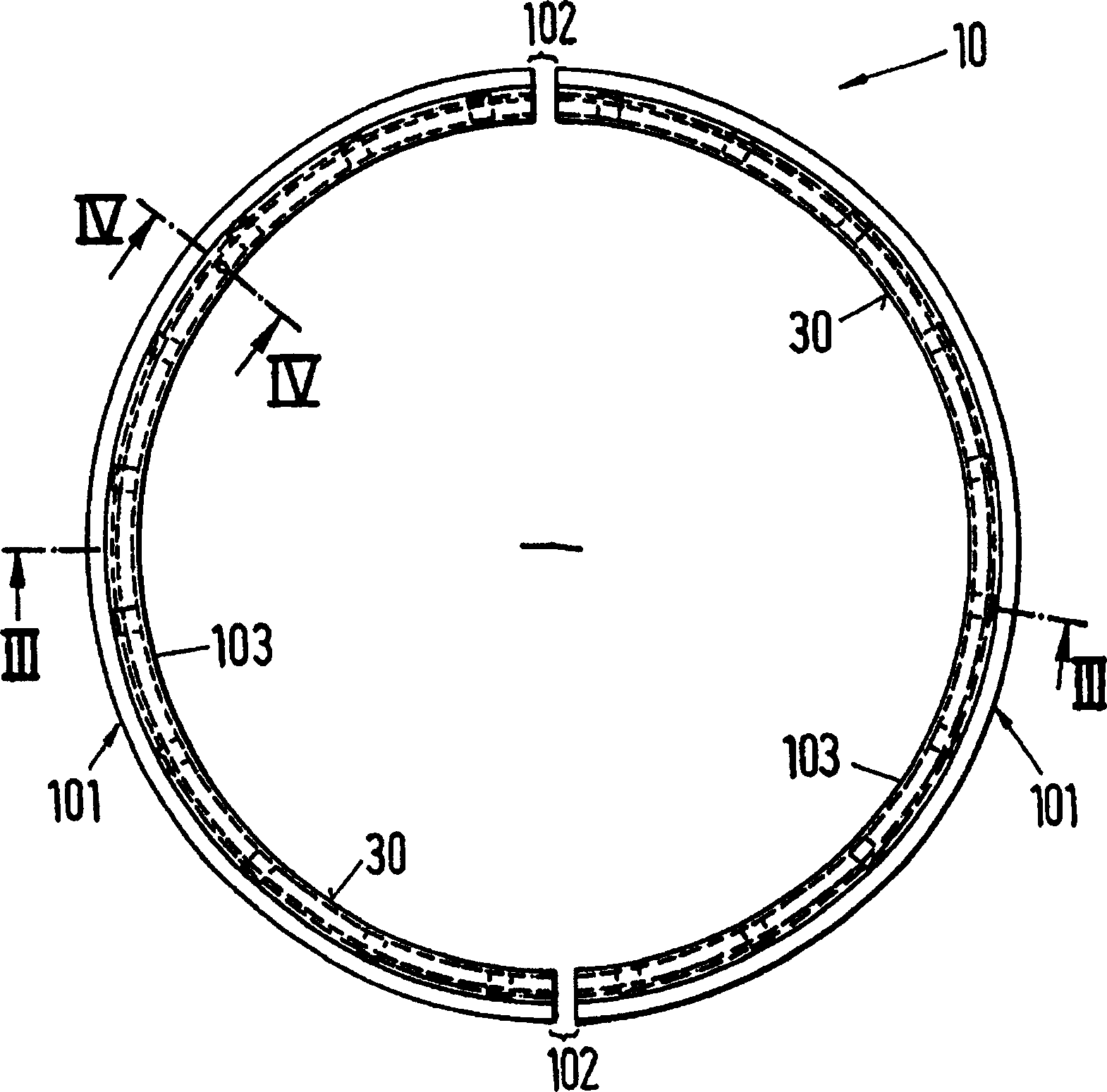

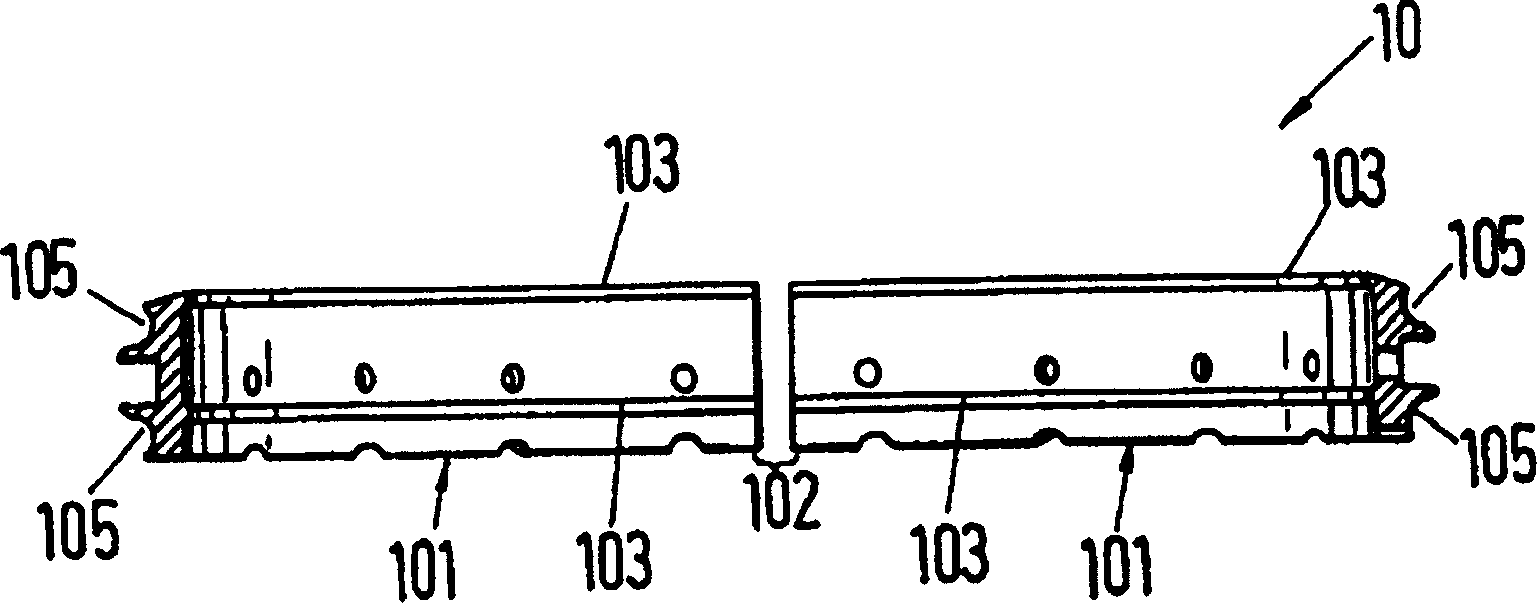

[0031] According to the invention, a stuffing box ring for a stuffing box of a two-stroke crosshead large diesel engine is proposed. As is well known, a diesel engine of this type used, for example, as a marine transmission has a plurality of cylinders, in each of which a reciprocating piston is arranged, which is passed through a piston rod 3 (see figure 1 ) is connected with a crosshead, and the other end of the crosshead is connected with the crankshaft through a push rod. The crosshead is linearly movably supported on a sliding track fixed in the crank chamber 5 of the engine housing, below the normal working position of the cylinder. The above-mentioned stuffing box is used for passing the piston rod 3 from the crank chamber 5 to the intake chamber 4 .

[0032] figure 1A cross-sectional view of a typical embodiment of a stuffing box for a longitudinally vented two-stroke crosshead large diesel engine is shown, the stuffing box generally indicated by reference numeral 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com