Subcritical rotating speed ball grinding mill

A critical speed and subcritical technology, applied in grain processing, etc., can solve the problems of difficult installation, complex and bulky structure, and restrictions on the popularization and application of "supercritical" speed mills, and achieve easy transformation, low cost and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

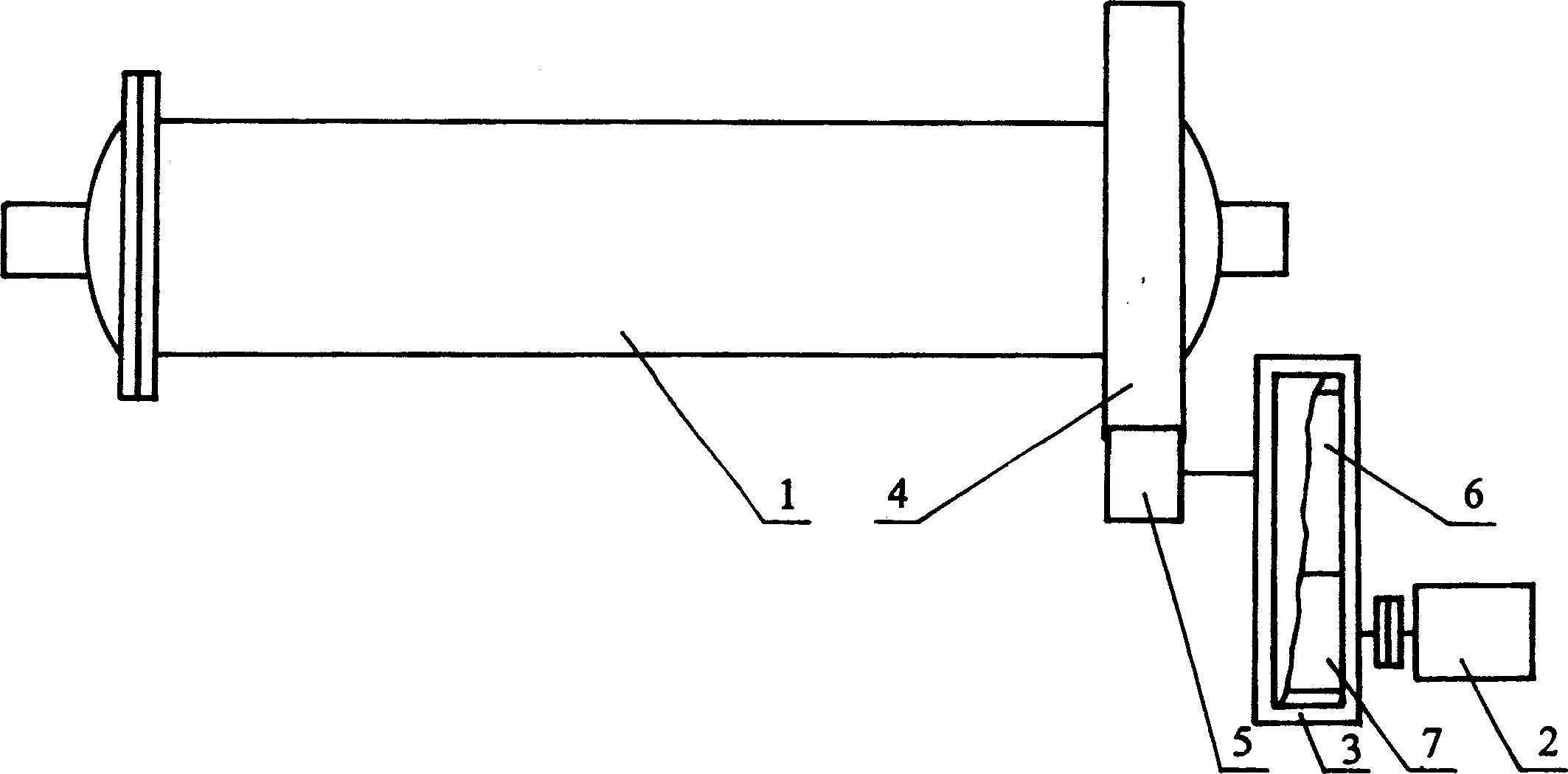

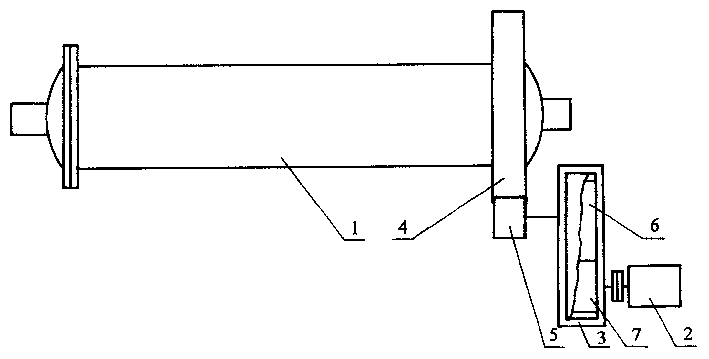

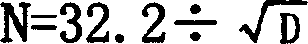

[0009] With reference to the accompanying drawings, the subcritical speed ball mill provided by the embodiment of the present invention includes a mill body 1, a motor 2, and a reduction box 3, and the mill body 1 is provided with a mill gear 4 and a mill pinion. 5. There is a pair of gears (6, 7) in the reduction box 3, the large gear 4 of the mill is connected with the pinion 5 of the mill, the pair of gears (6, 7) in the reduction box, and the motor 2 in turn, and the body of the mill 1 The subcritical speed is set between the design speed of the mill and the critical speed, and the subcritical speed N = 32.2 ÷ D × 1.05 ~ 1.198 , D is the diameter of the ball mill, that is to say, the subcritical speed is realized by adjusting the speed ratio of the reduction box 3, by changing the number of teeth of the gear pair (6, 7) in the reduction box, and the mil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com