Method of preparing large particle ammonium hydrogen carbonate

A technology of ammonium bicarbonate and large particles, applied in the direction of ammonium carbonate/acid carbonate, etc., can solve the problems of fine ammonium bicarbonate crystals, strong volatility, high consumption, etc., to reduce cycle load and buffer brush Corrosion, power-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

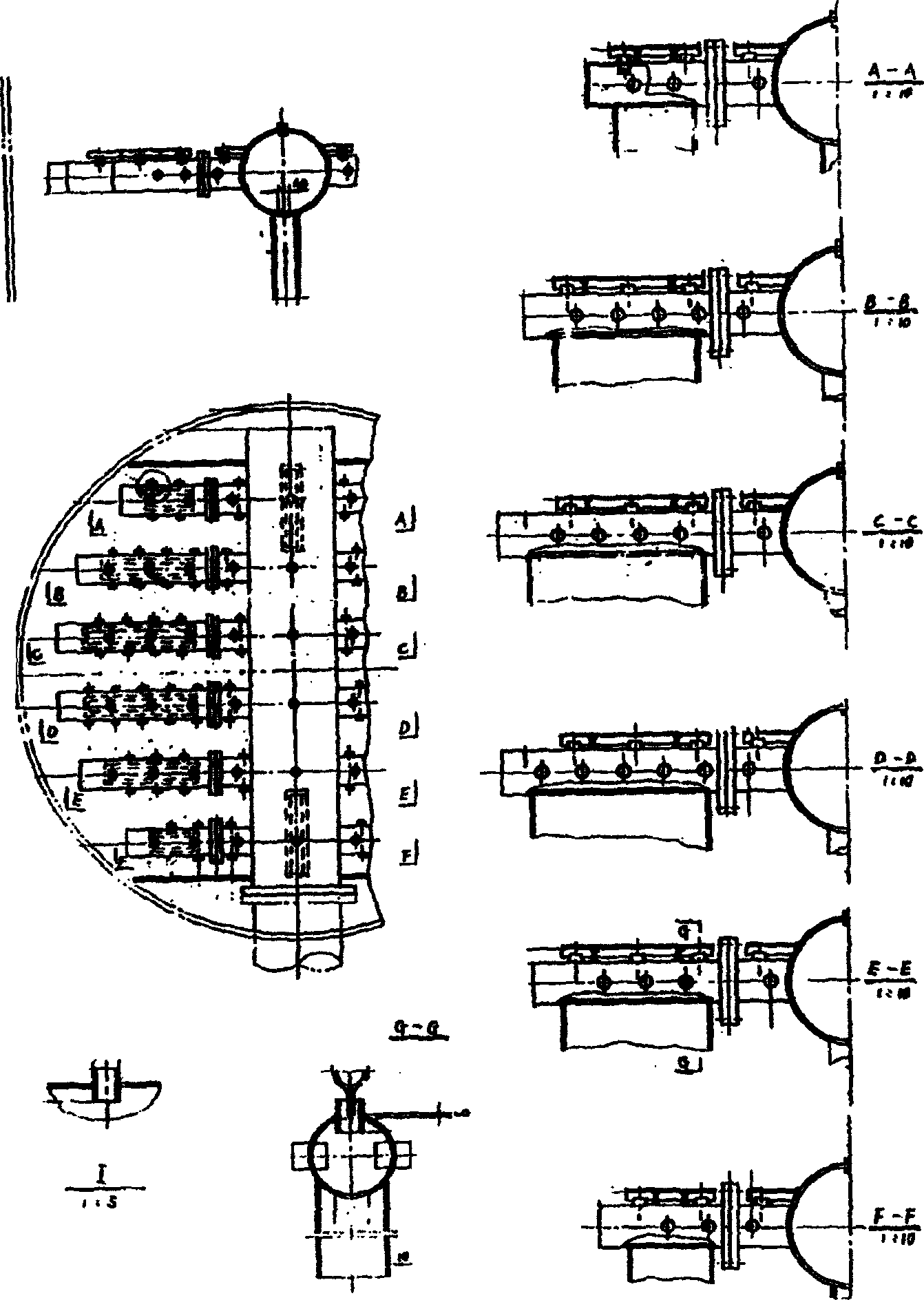

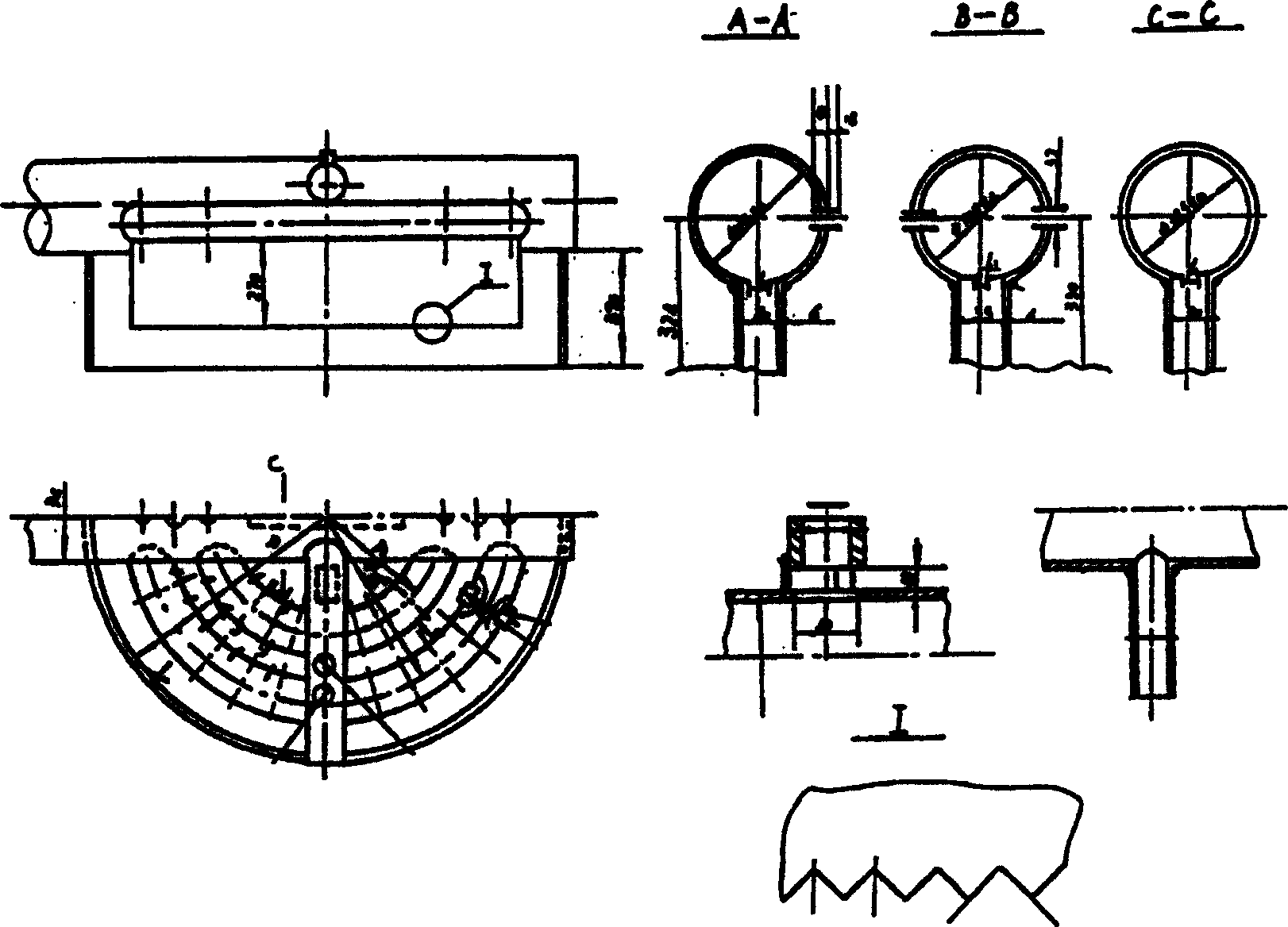

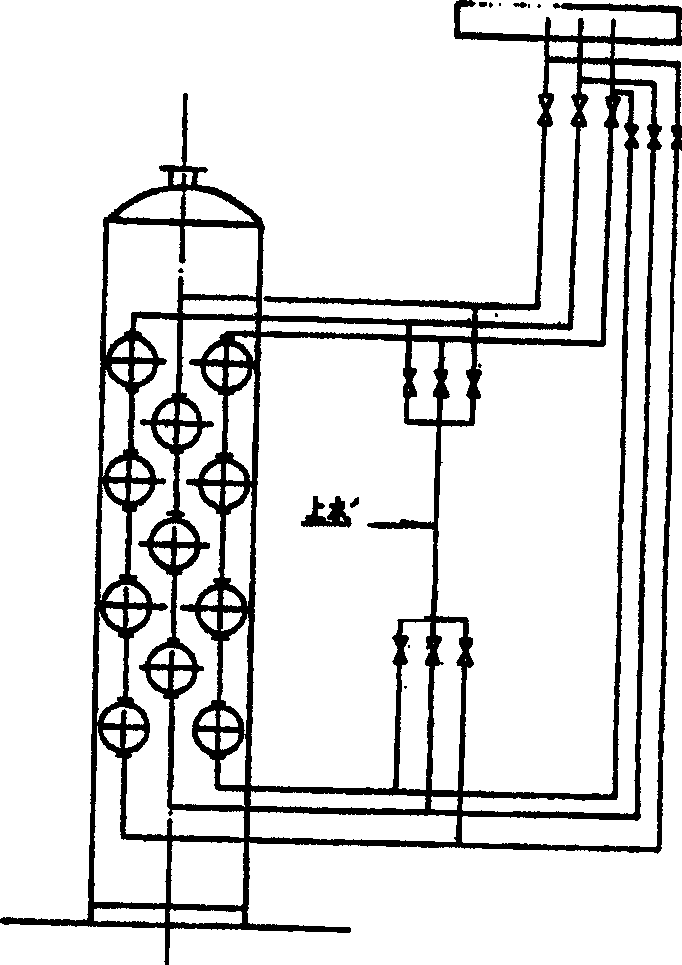

[0028] After construction according to the drawings, control the temperature of the upper part of the main tower within the range of 38-48 °C; the temperature of the lower part of the main tower within the range of 30-32 °C; the temperature of the lower part of the auxiliary tower 40-48 °C; the temperature of the upper part of the auxiliary tower ≤36 °C; The gas composition is controlled within the range of 13-15%; the cooling water is poured first when the tower is inverted, and the main tower is then inverted after creating the conditions for the main tower.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com