Hydraulic cylinder

A technology of cylinder chamber and cylinder barrel, which is applied in the field of cylinder and position detection sensor, which can solve the problems such as difficult to reduce size and weight, large converter body, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Next, the cylinder in the embodiment of the present invention will be described first, and then the position detection sensor mounted on the cylinder in the embodiment of the present invention will be described.

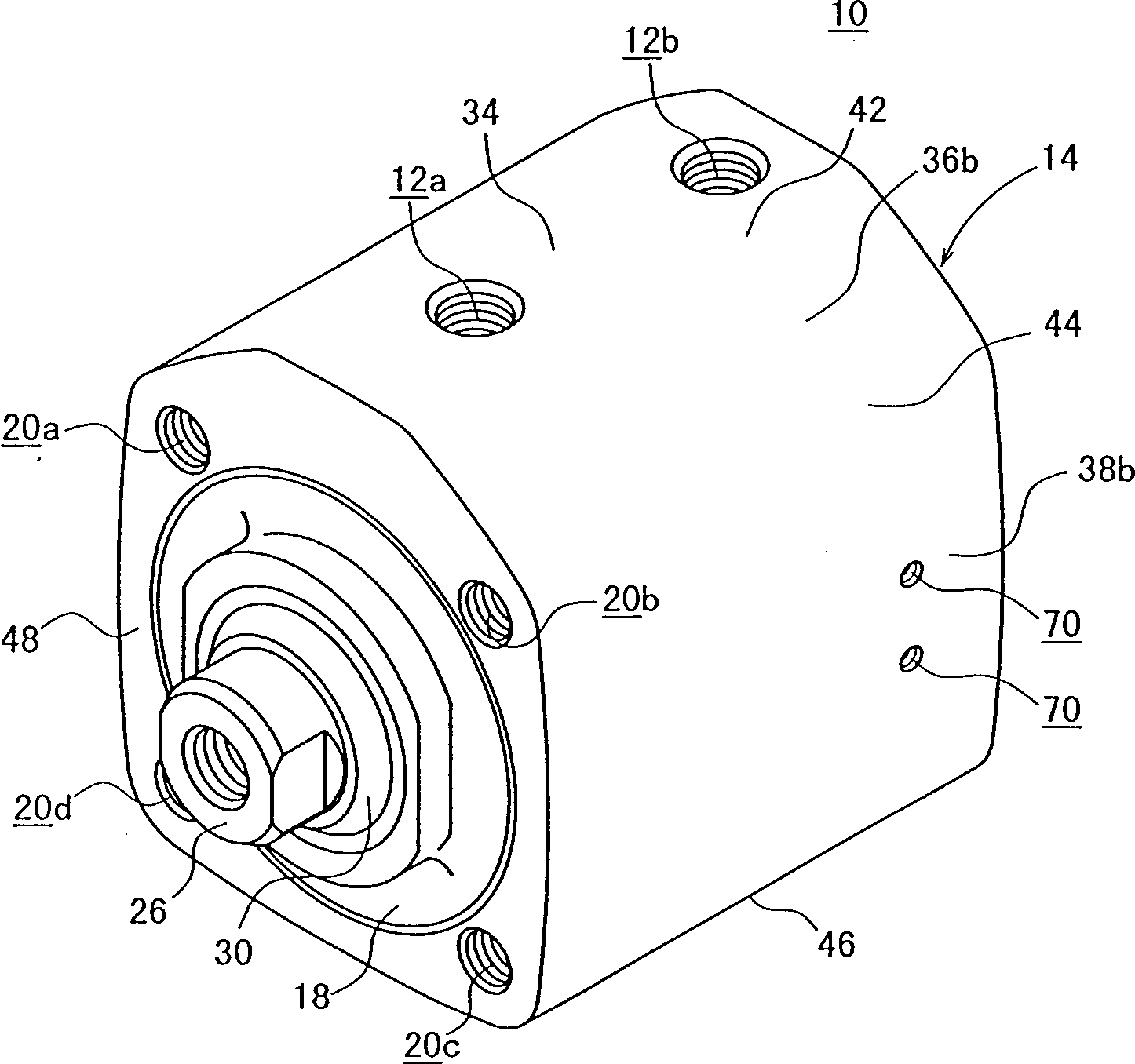

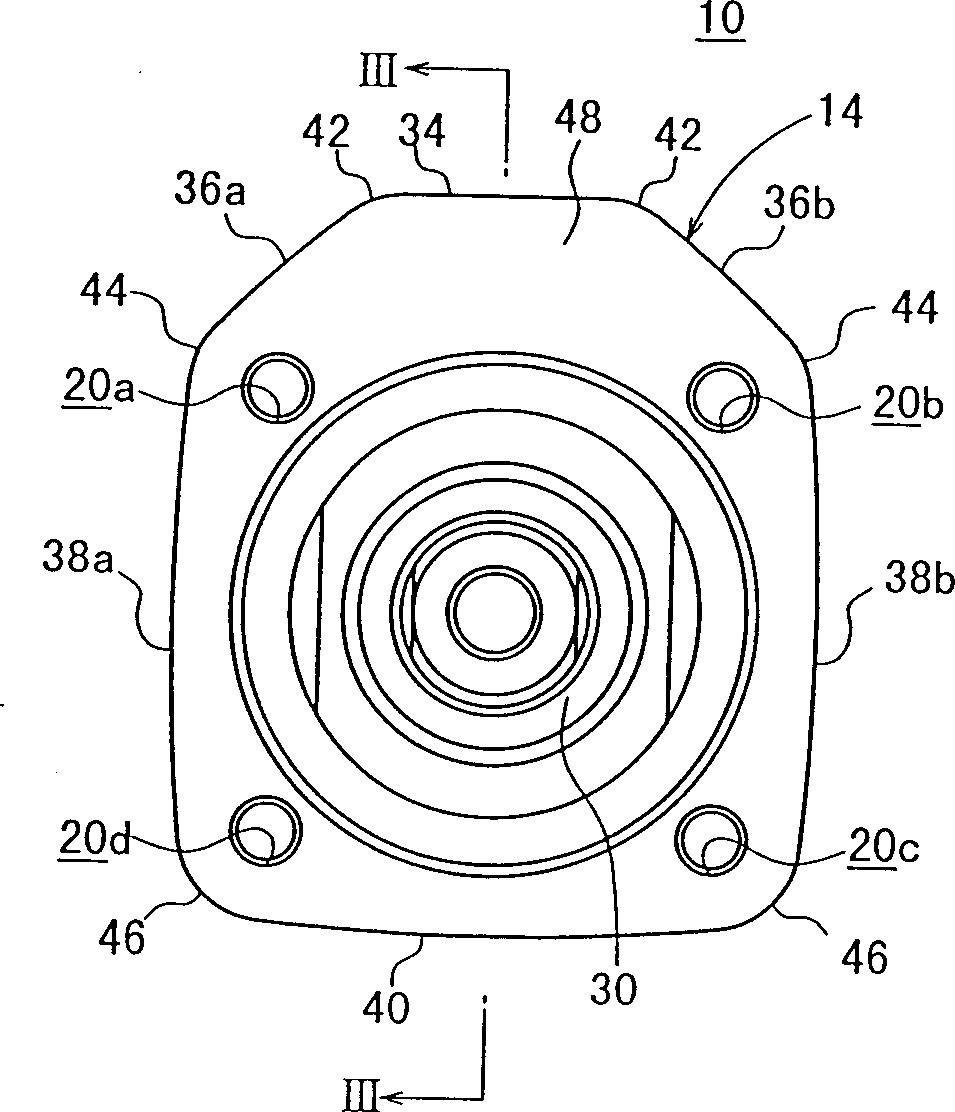

[0049] The cylinder represented by reference numeral 10 comprises: a substantially cylindrical cylinder 14 having a pair of pressurized fluid inlets / outlets 12a and 12b separated by a predetermined distance; and a rod sleeve 18 fitted in a threaded hole on the other end of the cylinder 14 .

[0050] In the cylinder 14, there are four mounting holes 20a to 20d extending in the axial direction. By tightening unrepresented screws in the threaded portions of the mounting holes 20a to 20d, or by tightening unrepresented bolts in the mounting holes 20a to 20d, the cylinder 10 can be easily mounted on a wall surface or the like. superior.

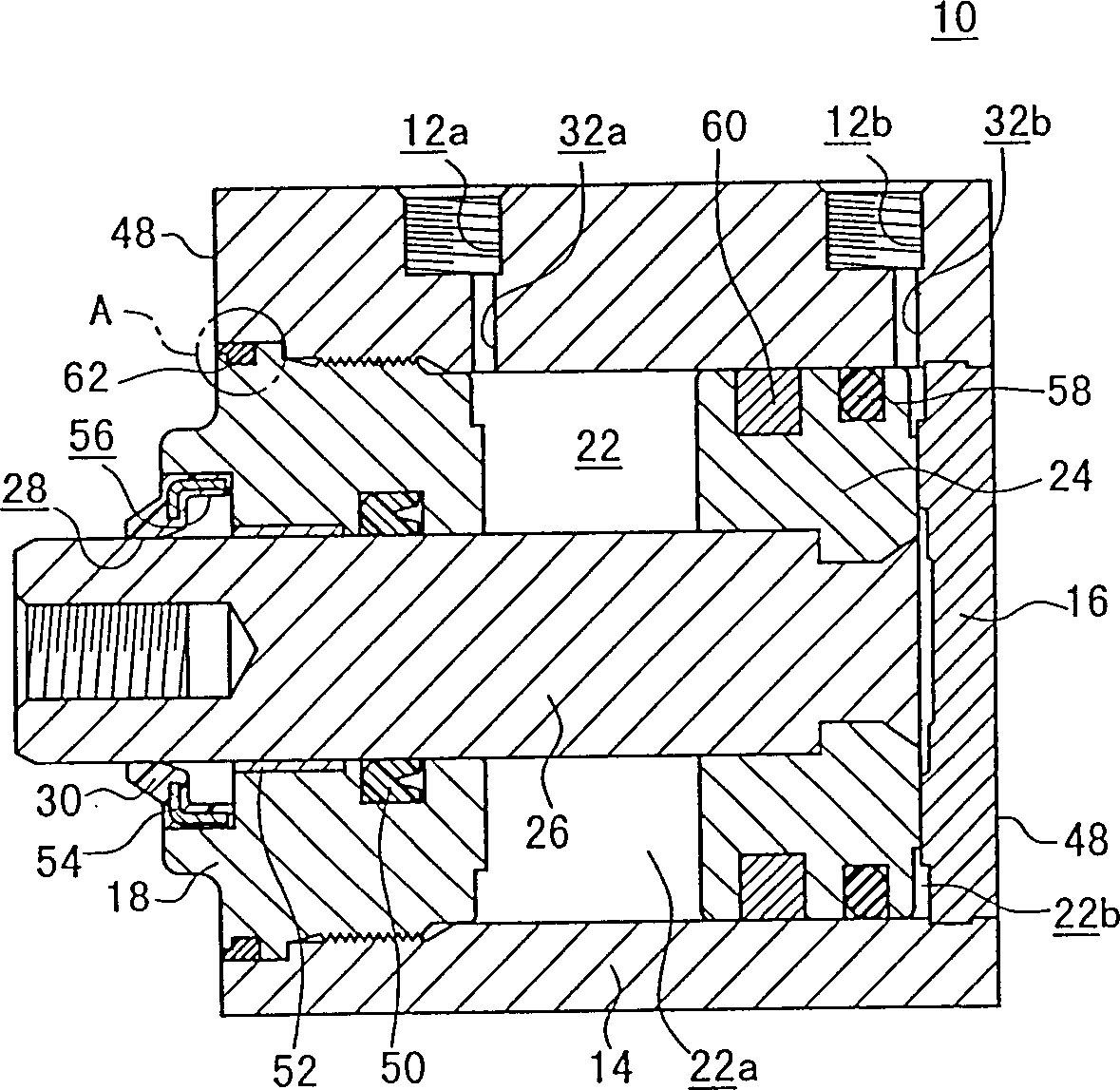

[0051] Such as image 3As shown, the cylinder 10 also includes: a piston 24, which can move along the cylinder chamber 22 def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com