Two-stroke diesel engine starting, braking and reverse method, its device and application

A diesel engine, two-stroke technology, applied in the direction of starting device with mechanical power storage, engine components, engine control, etc., can solve problems such as braking or reversing the difficulty of two-stroke diesel engines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

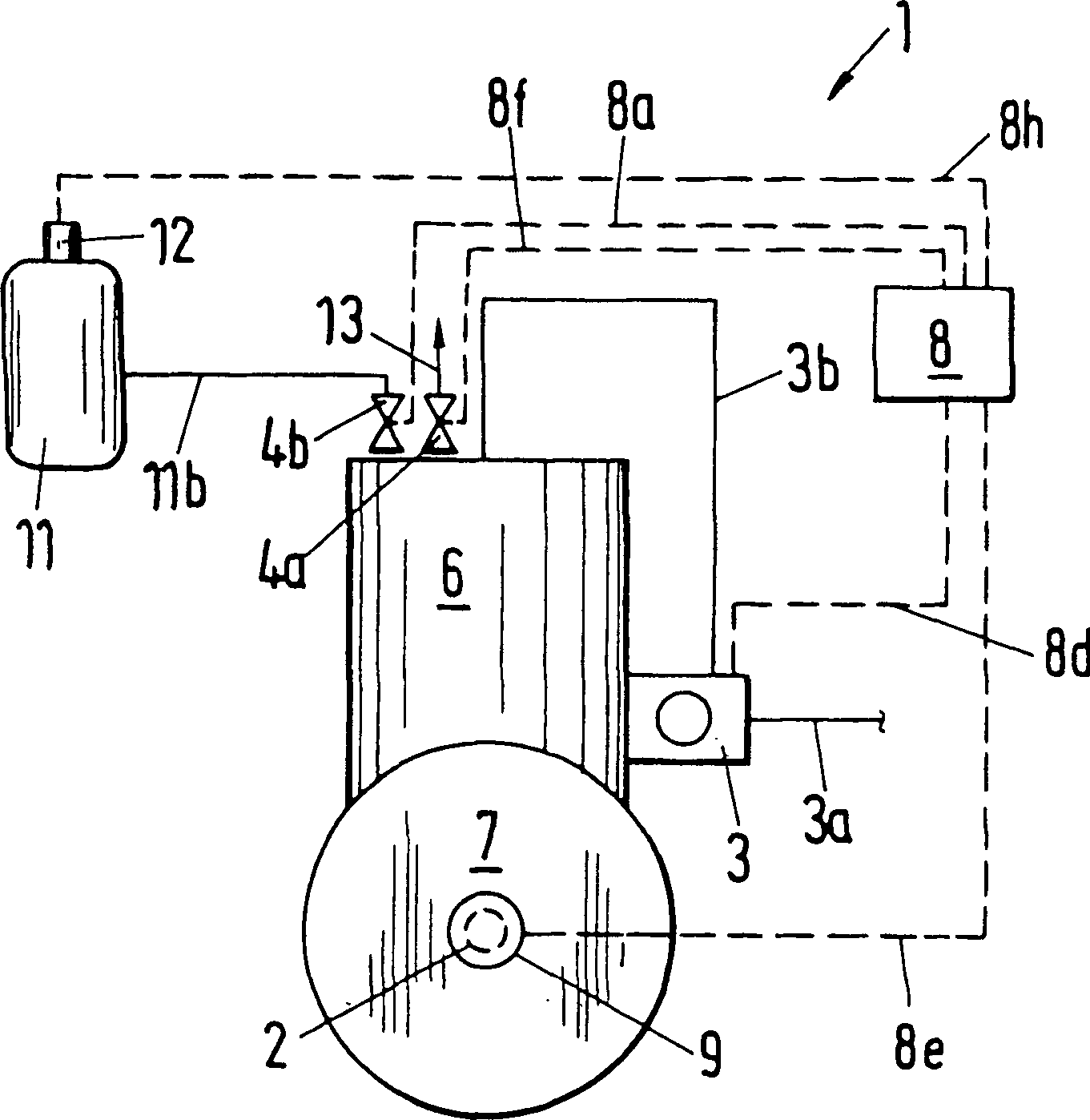

[0018] figure 1 The schematic two-stroke diesel engine includes a cylinder block 6 with a plurality of cylinders, each cylinder with an injection pump 3 equipped with delivery lines 3a, 3d, and a crankcase 7 with a crankshaft 2 installed. The excitation and regulating device 8 is connected to the

[0019] - connected to the angle sensor 9 for measuring the angle of rotation of the crankshaft 2,

[0020] - connected to an exhaust valve 4a

[0021] - connected to a compressed air valve 4b

[0022] - connected to jet pump 3,

[0023] - and connected to a sensor 12 for measuring the pressure in the compressed air volume 11 .

[0024] Compressed air is delivered from the compressed air container 11 to the compressed air valve 4b via the line 11b. An exhaust pipe 13 is provided after the exhaust valve 4a.

[0025] Two-stroke diesel engines receive air through the intake ports, which are located in the cylinders but are not visible in the diagram.

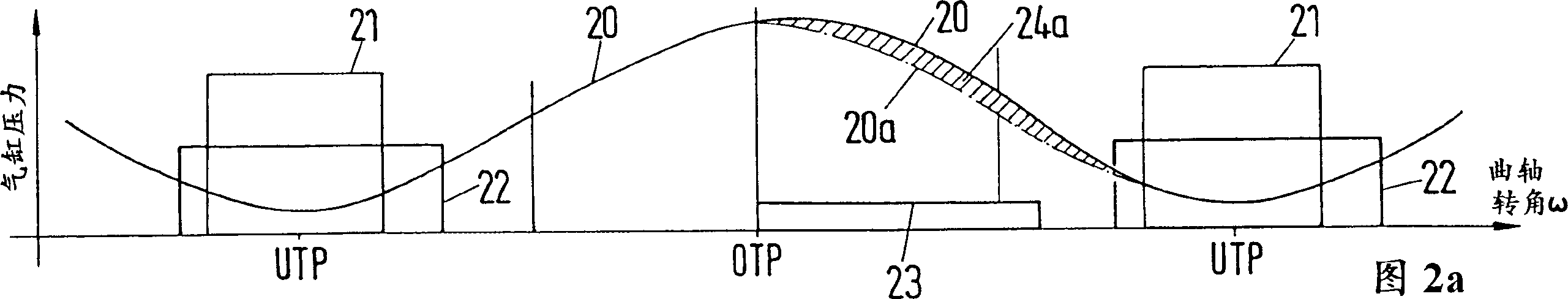

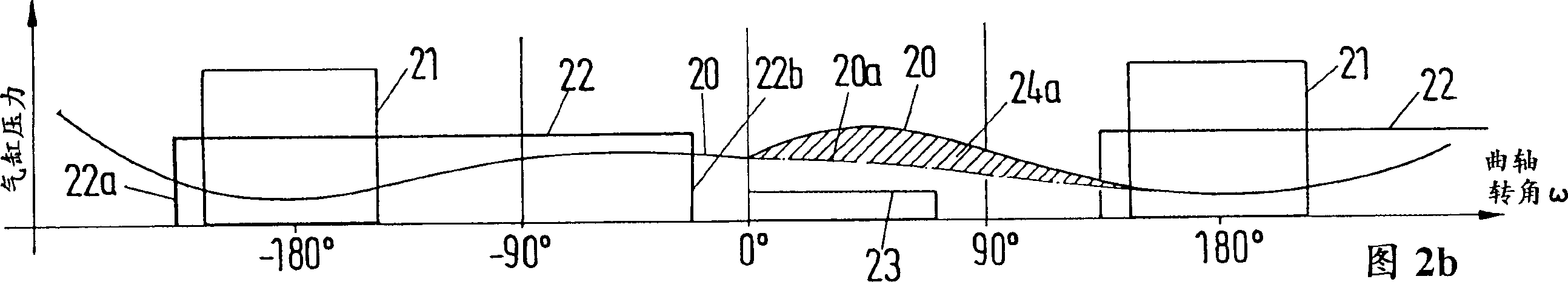

[0026] FIG. 2 a shows the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com