Lead-acid accumulator with coil structure and manufacturing method thereof

A lead-acid battery and a manufacturing method technology are applied in the directions of lead-acid battery, lead-acid battery construction, final product manufacturing, etc. Due to the complex manufacturing process and the poor deformation ability of active materials, the effects of avoiding micro-short circuit of the electrode plate, strong rapid charging and discharging ability, and increased contact area are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

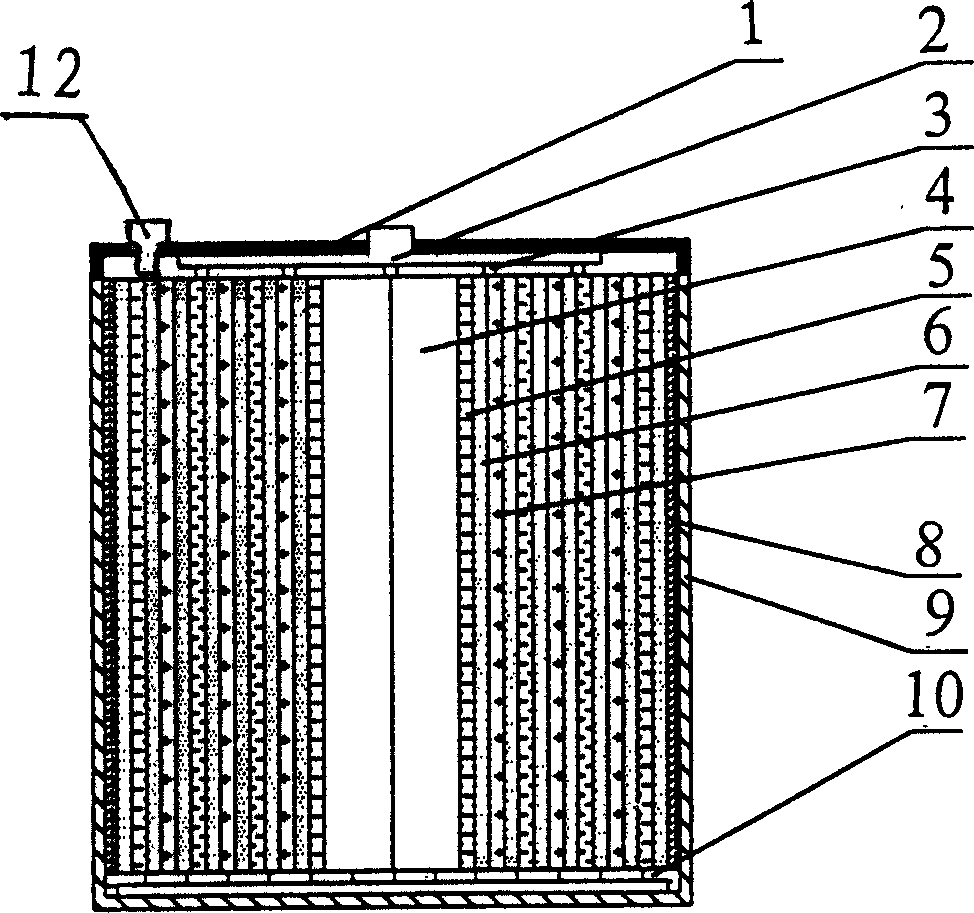

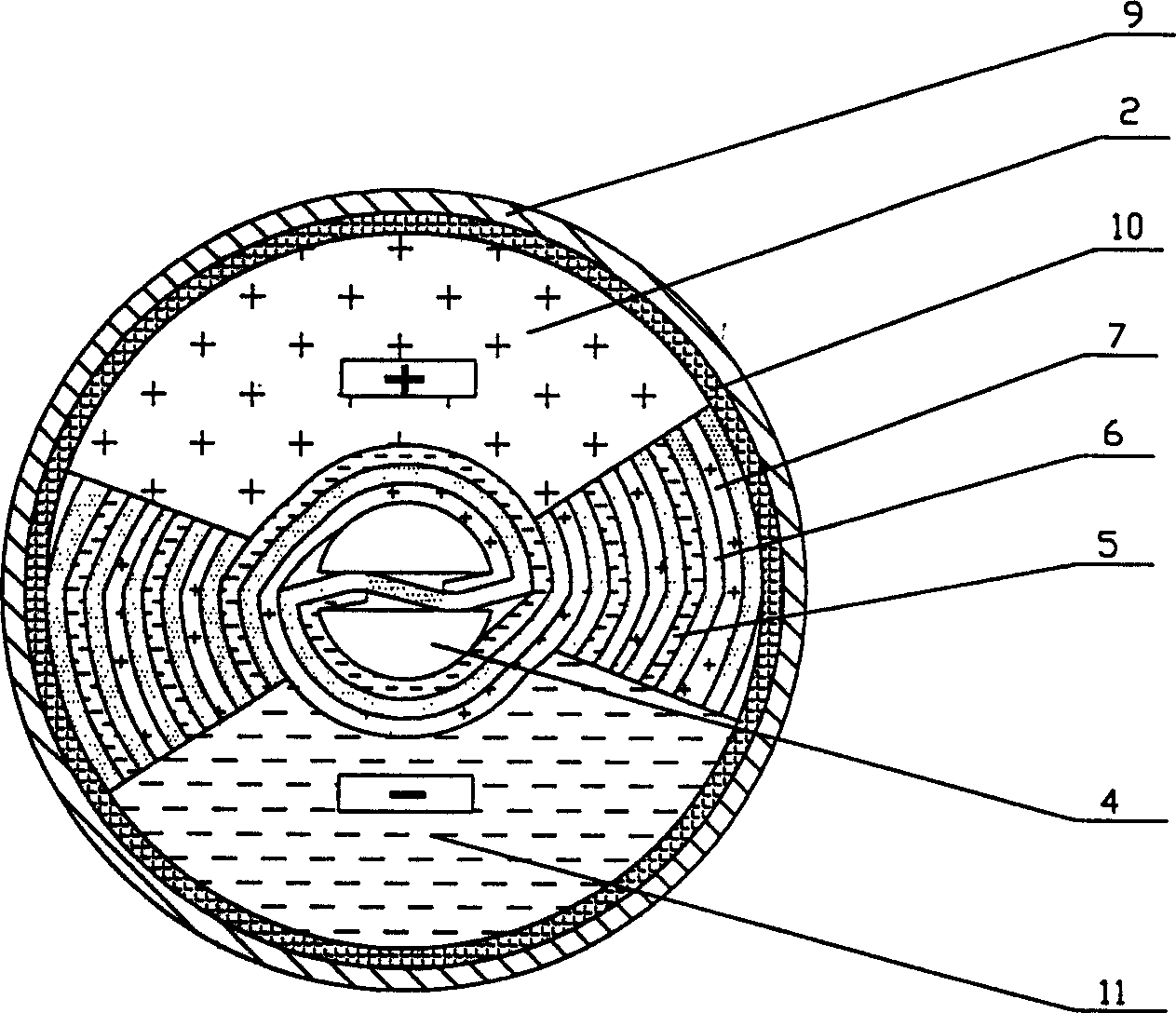

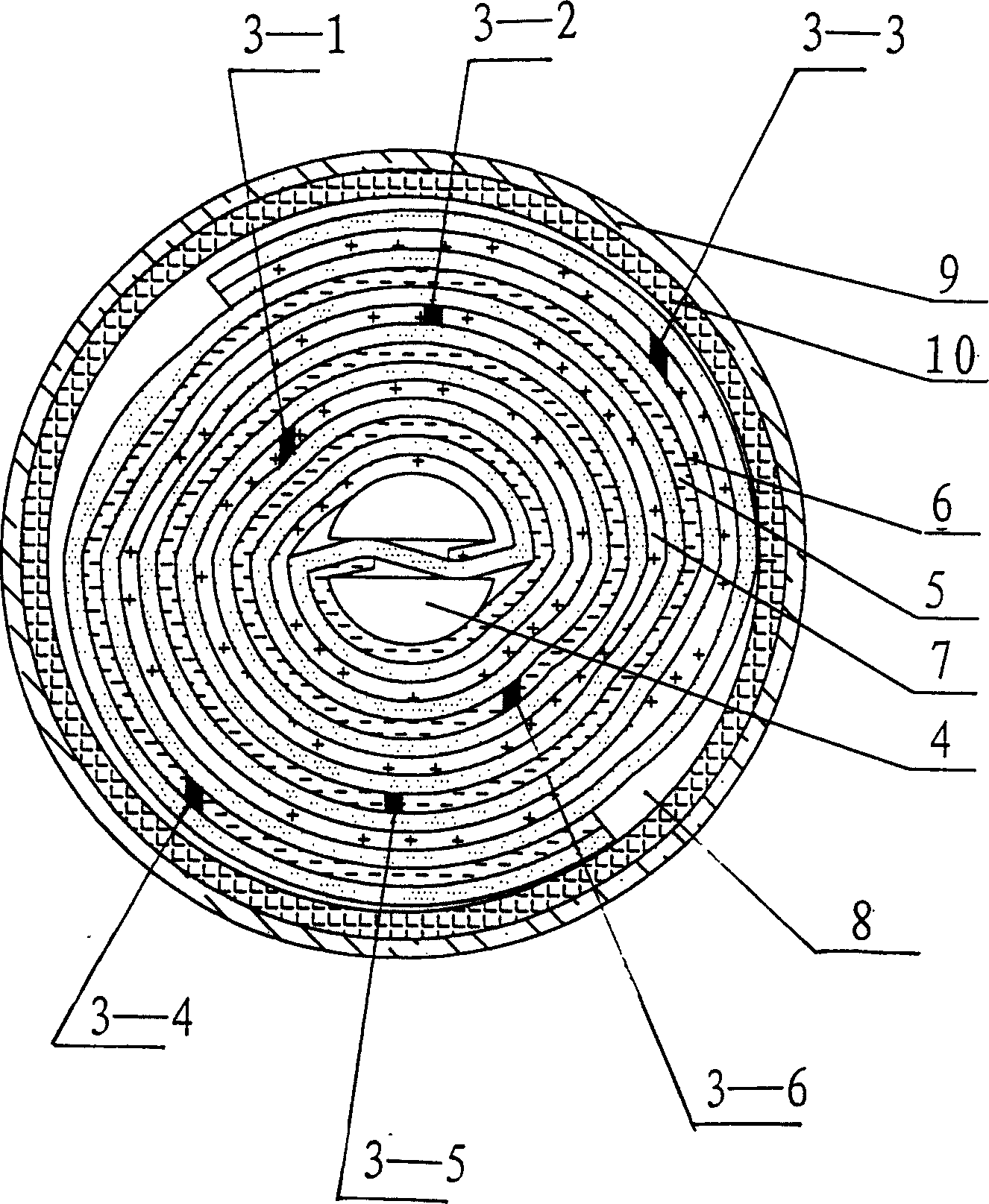

[0040] like Figure 1 to Figure 8Shown: a lead-acid battery with winding structure, including battery box cover 1, positive terminal 2, tab 3, mandrel 4, negative plate 5, separator 6, positive plate 7, outer circular fixture 8, battery box 9. Grid bottom support 10, negative terminal 11, exhaust valve 12, lead grid 13, electrolyte 14, the tab 3 is connected to the positive plate 7 and the negative plate 5, and the tab 3 is a metal sheet, It is woven in the lead mesh and connected with the lead mesh, and one side protrudes from the edge of the lead mesh for terminal welding. The positive plate 7, the separator 6, and the negative plate 5 are wound on the mandrel 4 in a hierarchical order to form the battery core 19 of the lead-acid storage battery with the winding structure. Hook, the other end is provided with the outer circular jig 8 that a plastic sheet of the hole that matches with this barb tooth hook is fixed; The positive and negative pole lug 3 that stretches out the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com