Assemby device

An assembly device and assembly table technology, which is applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of reduced assembly accuracy, limited device refitability, configurability and accessibility, deterioration, etc. The large amount of parts loaded per unit time is beneficial to accessibility and the effect of improving the speed of loading parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

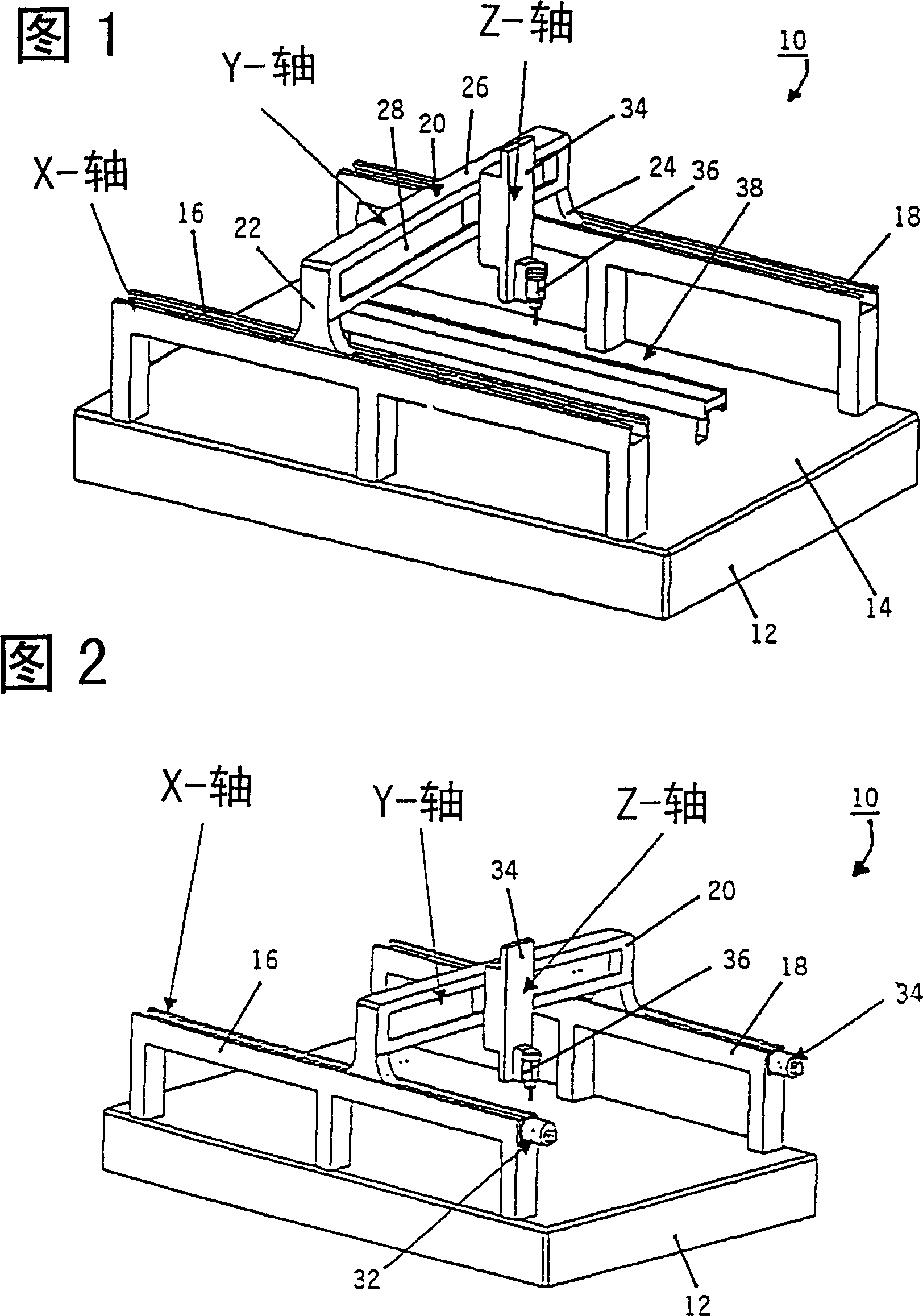

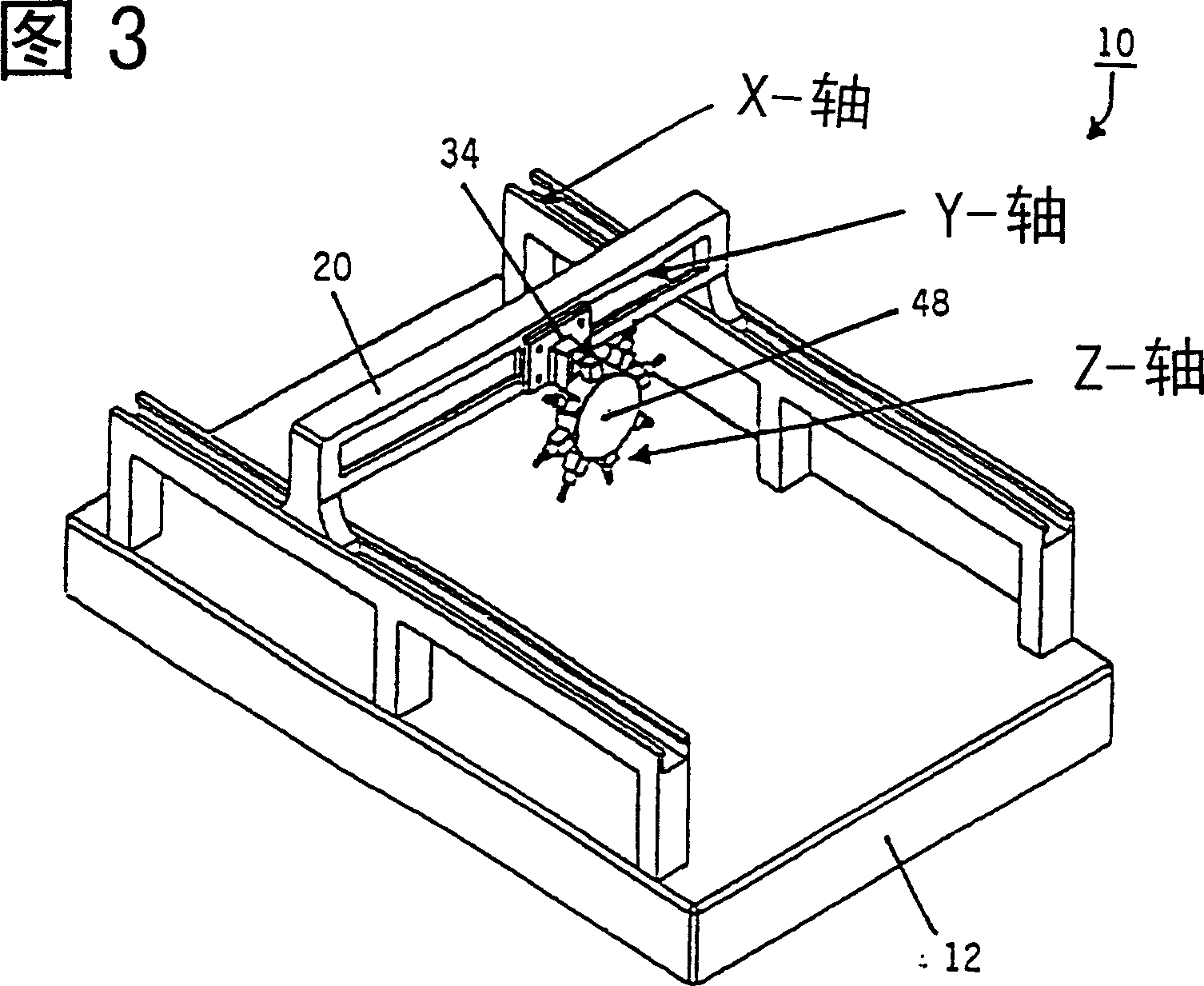

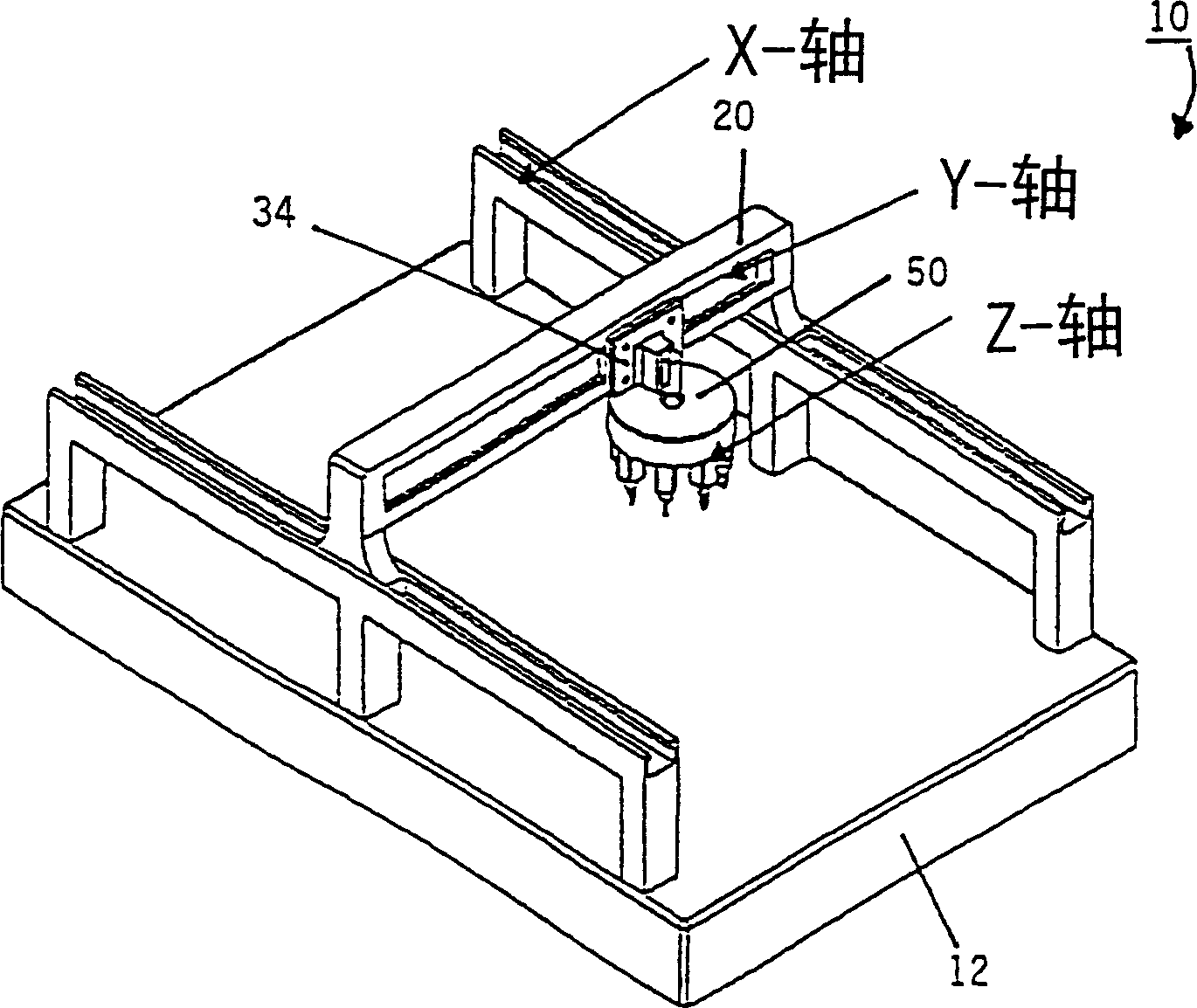

[0027] FIG. 1 shows a first exemplary embodiment of an assembly device 10 , which is used in particular as a fully automatic assembly device for the production of microsystems technology products and for carrying out assembly tasks in the semiconductor industry. Assembly device 10 has an assembly table 12 with an assembly surface or table top 14 . A conveyor system 16 , 18 is arranged on the table 14 . The conveyor system 16 , 18 consists of a rail system with two rails 16 , 18 arranged parallel to one another. It can also be seen that the guide rails 16 , 18 rest on the top of the assembly table 12 or on the top of the assembly table 14 . However, it is also possible to accommodate the conveyor systems 16 , 18 in the table top, that is to say on the assembly table, or to be articulated directly on the machine chassis in order to achieve an optimal introduction of forces into the supporting machine parts.

[0028] The gantry 20 is moved by means of the conveyor systems 16 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com