Rhombic intensified heat exchange trbe

A technology of heat exchange tubes and rhombuses, which is applied in the field of enhanced heat exchange elements and diamond-shaped enhanced heat exchange tubes, can solve the problems of increased flow resistance or power consumption, increased manufacturing costs of enhanced tubes, and reduced economic benefits, etc., to achieve synergy Effect of degree improvement, flow resistance increase, good anti-fouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific structure of the present invention will be further described below in conjunction with the accompanying drawings.

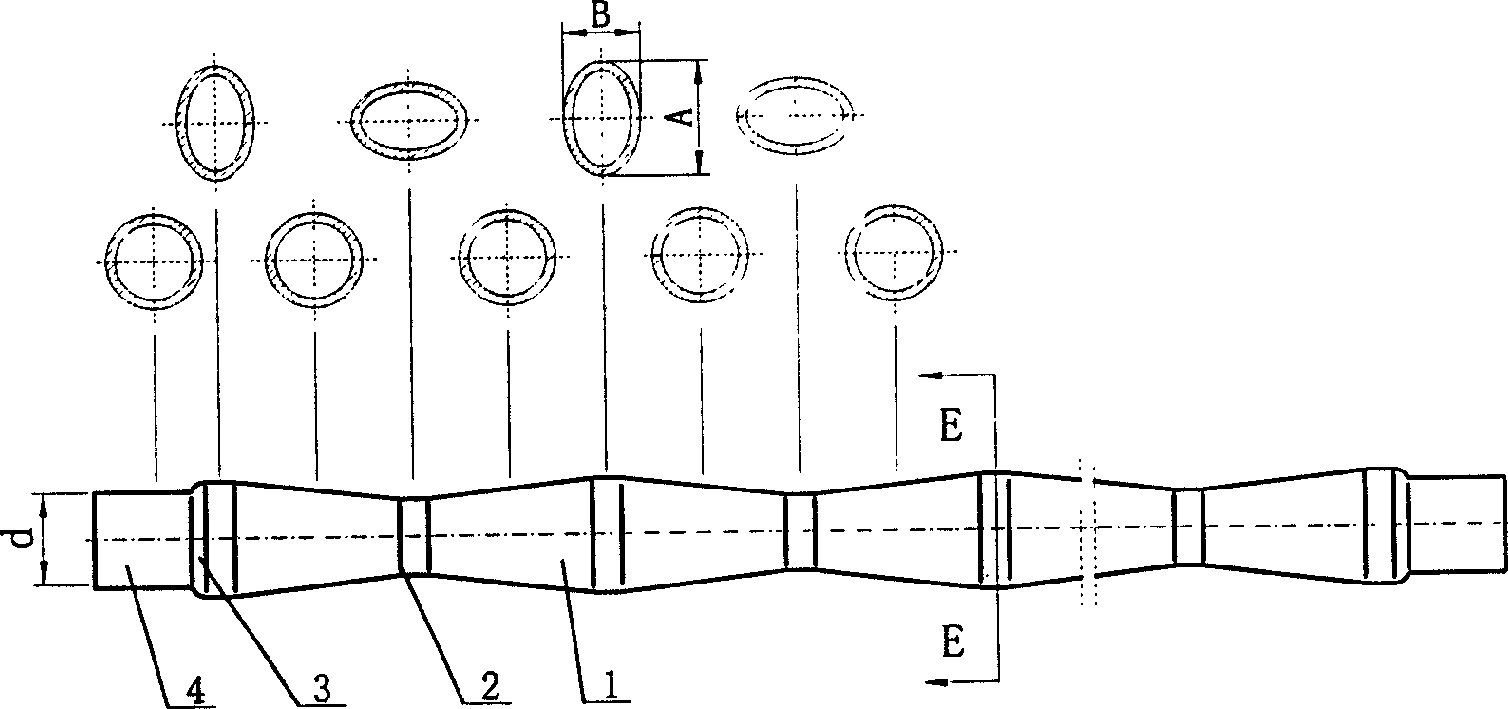

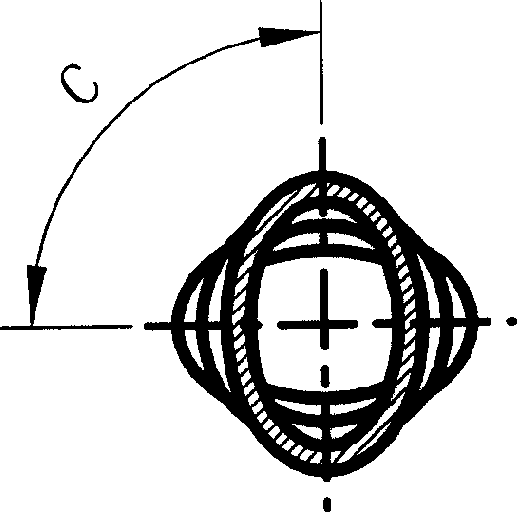

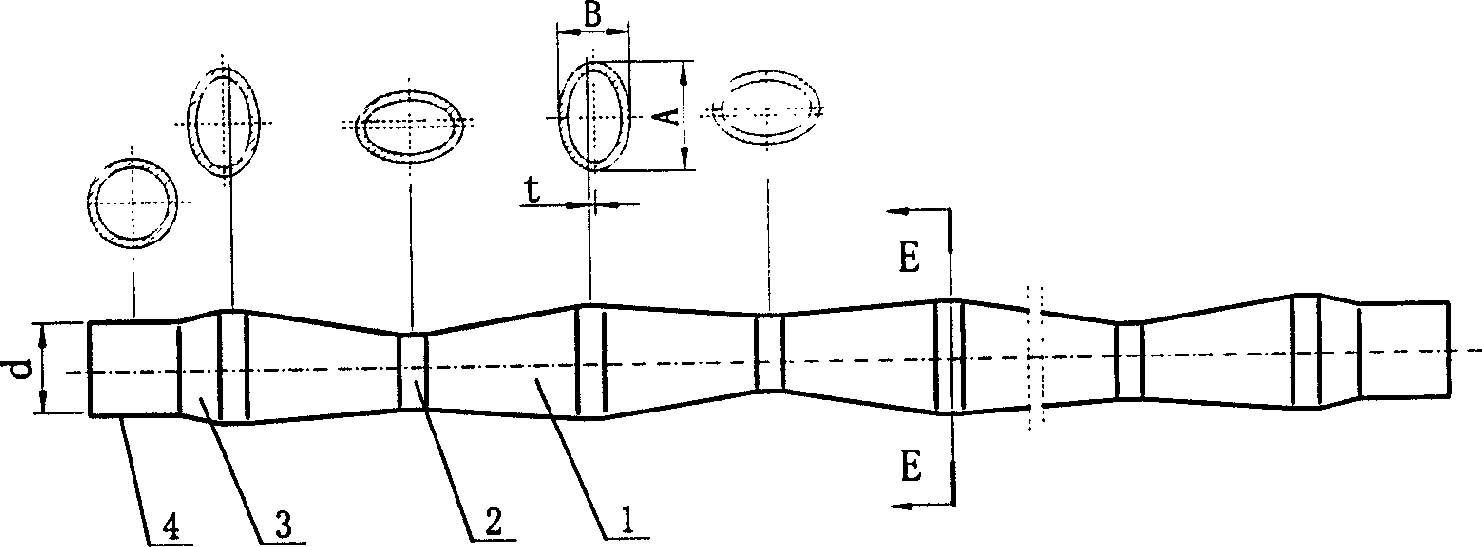

[0019] figure 1 It is a schematic diagram of the structure of a rhomboid tube made of an ordinary round tube. The entire rhombus pipe is composed of several rhombus pipe sections 1, ellipse pipe sections 2, circular-elliptical transition pipe sections 3 and circular pipe sections 4 at both ends. There are very short elliptical pipe sections 2 at both ends of each rhombic pipe section (for the forming of the rhomboid pipe section). The rhomboid pipe section and the elliptical pipe section are arranged periodically in turn, and the rhomboid pipe section is the main body of heat exchange. The ellipticity of the cross-section gradually decreases from both ends of the rhombus pipe section to the center until the central cross-section of the pipe section becomes circular (or approximately circular).

[0020] The entire rhomboid tube is made of a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com