Method for making long period optical fibre grating

A fiber grating and manufacturing method technology, applied in the field of optical fiber communication and optical fiber sensing, can solve the problems of uneven angular distribution of optical fiber, bending deformation of LPFG, etc., and achieve the effects of eliminating physical deformation, reducing polarization-related loss, and being easy and controllable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The best embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

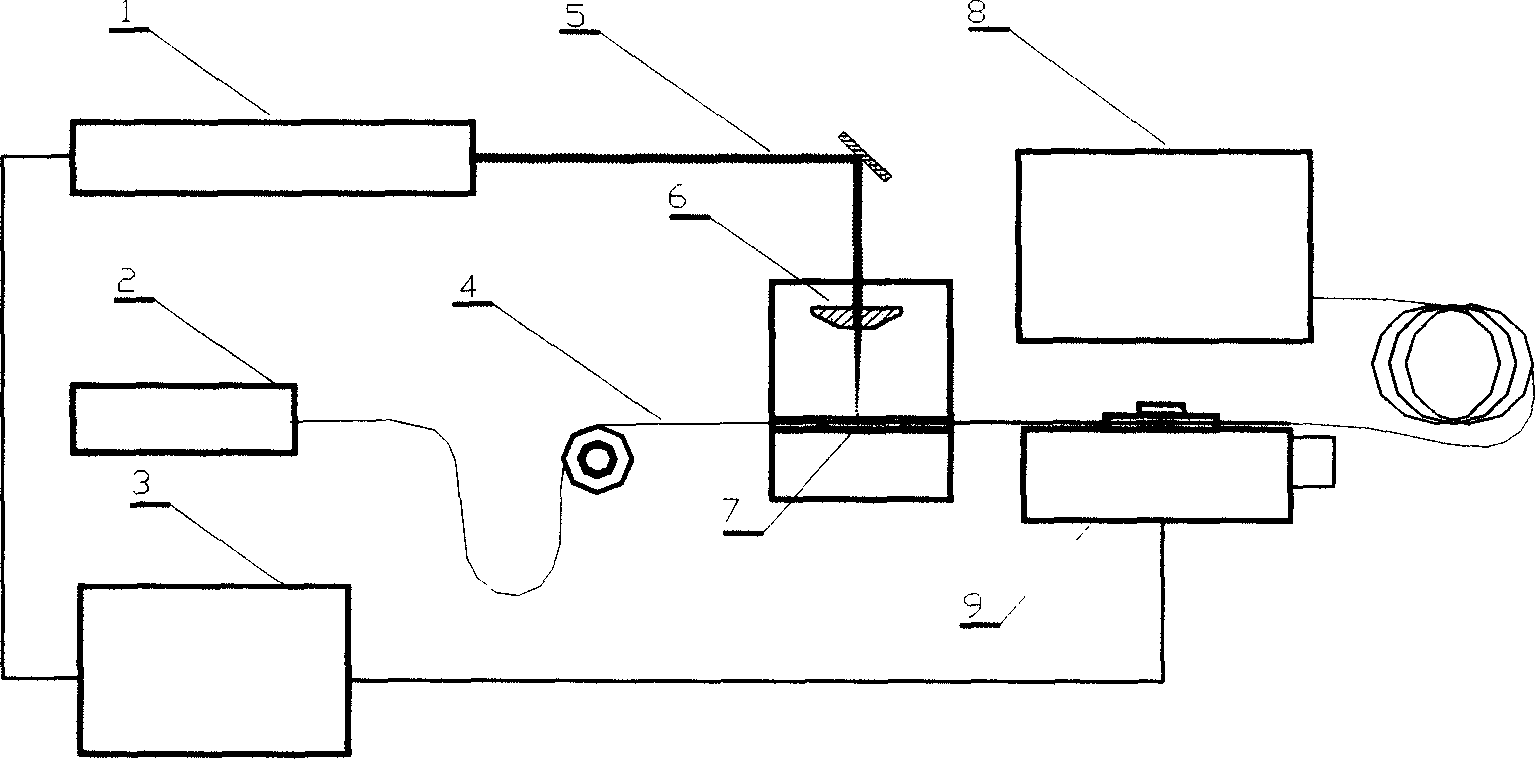

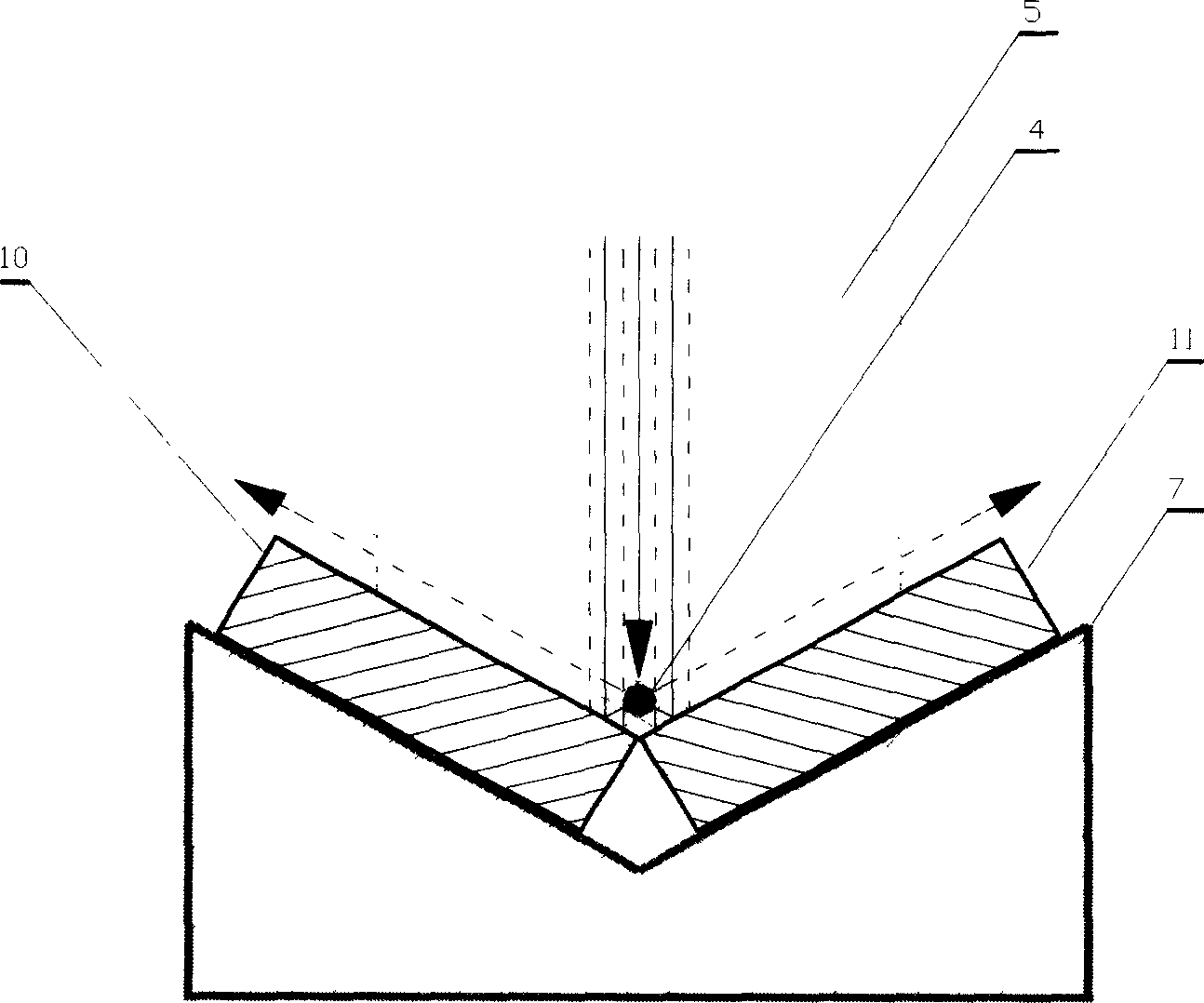

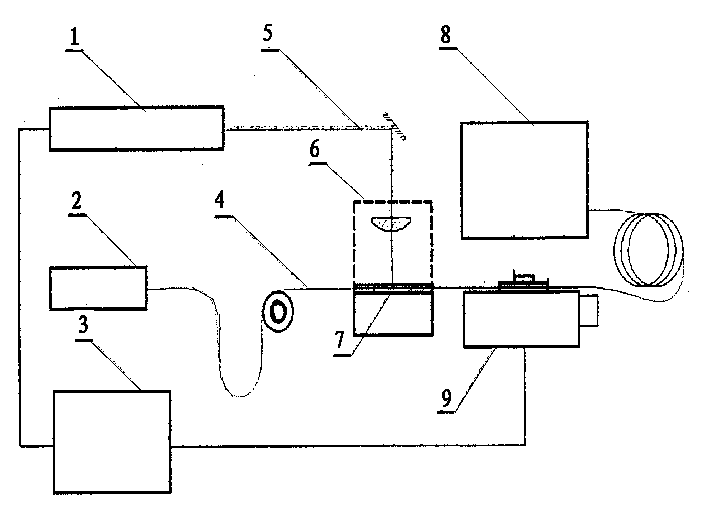

[0013] First according to CO 2 The operating characteristics of the laser are used to determine the parameters of the laser, such as operating frequency, duty cycle, and number of laser pulses. The frequency of the laser pulse used in the present invention is between 20k-24kHz, and the laser energy irradiated on the single-mode optical fiber (4) can be changed by adjusting the frequency and duty ratio of the laser pulse and the quantity of the laser pulse. Secondly, according to the resonant wavelength, peak loss, and bandwidth of the LPFG to be produced, determine the period of the LPFG and the length of the grating. The period number of the LPFG to be written can be calculated from the above two parameters, so that the electronically controlled translation stage (9) parameters are set. Place the bare fiber on the LPFG writing platform (7) e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com