Method for regulating pump transport volume

A technology of pump delivery and compensation, applied in pump control, pump test, flow control, etc., can solve problems such as deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

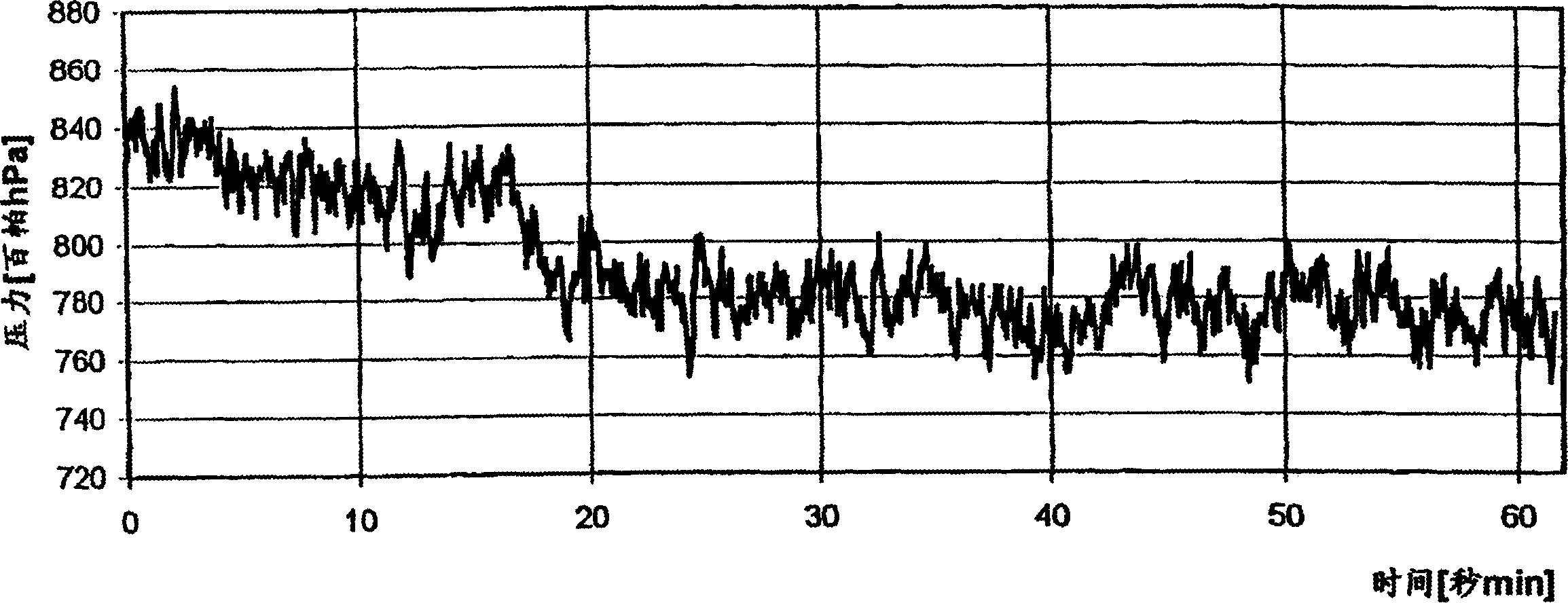

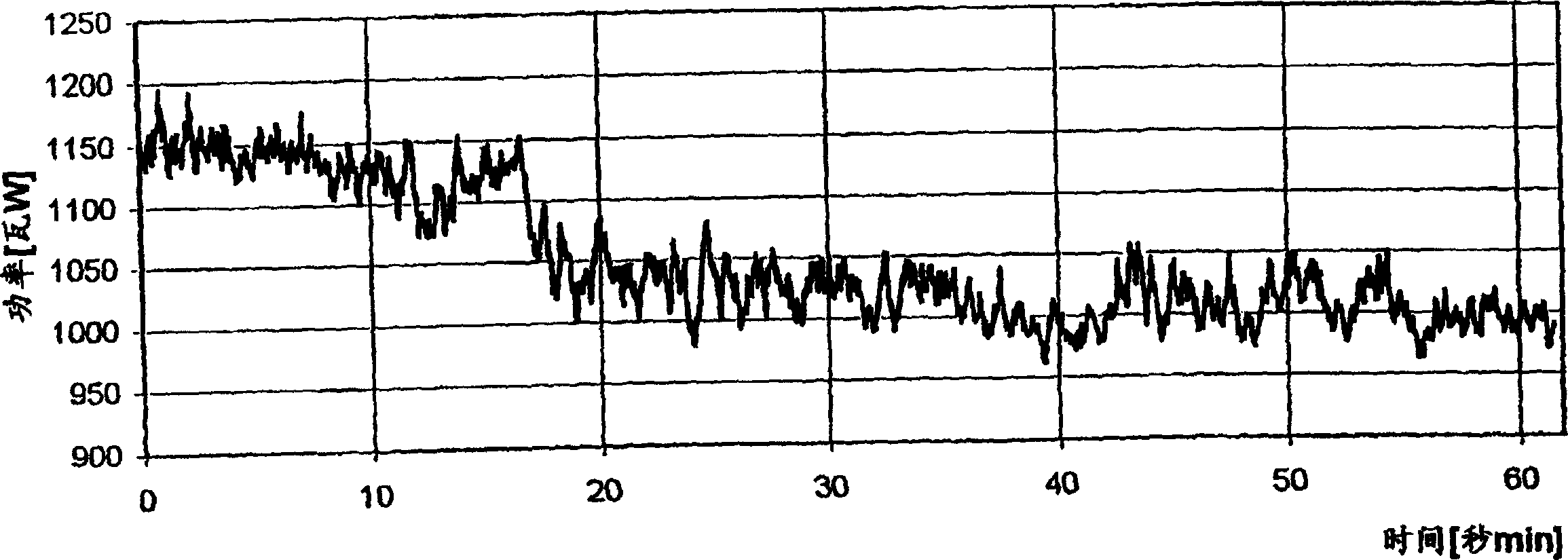

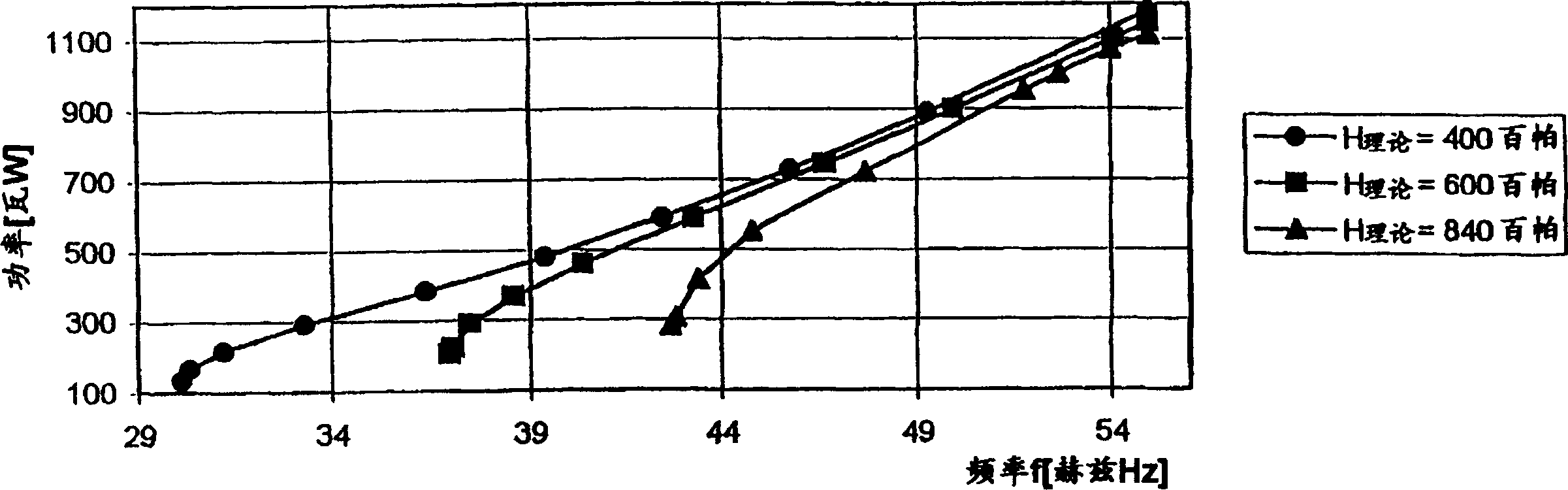

[0022] first according to Figures 1 to 3 To explain in detail the purpose of the invention based on the method of the present invention.

[0023] Figures 1 to 3 Curves determined empirically are plotted. according to figure 1 and 2 The curves in the figure show the delivery rate in the traditional regulation method, that is, the pressure and flow are regulated by the motor-driven pump instead of being directly measured, the pressure ( figure 1 ) and the power supplied to the motor ( figure 2 ) and time t. It is known to measure the input power P of the motor, in particular the active power and not the apparent or reactive power, as the magnitude of the actual value of the delivered quantity. For the inspection motor is related to the asynchronous motor (also known as induction motor) with a rated power of 1.5kW (kilowatt), the number of revolutions of the motor is controlled by changing its operating voltage frequency through a frequency converter.

[0024] according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com