In-line destresing process and apparatus for Cu-alloy pipe wire

A treatment method and a treatment device technology, which are applied in the production of copper alloy continuous casting and rolling pipes and wires, on-line stress relief treatment methods and special devices for copper alloy pipes and wires, and can solve the problem of limited space in annealing furnaces, small equipment footprints, and problems in annealing Low efficiency and other problems, achieve continuous high-efficiency online annealing, ensure continuous production process, and fast annealing treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 25

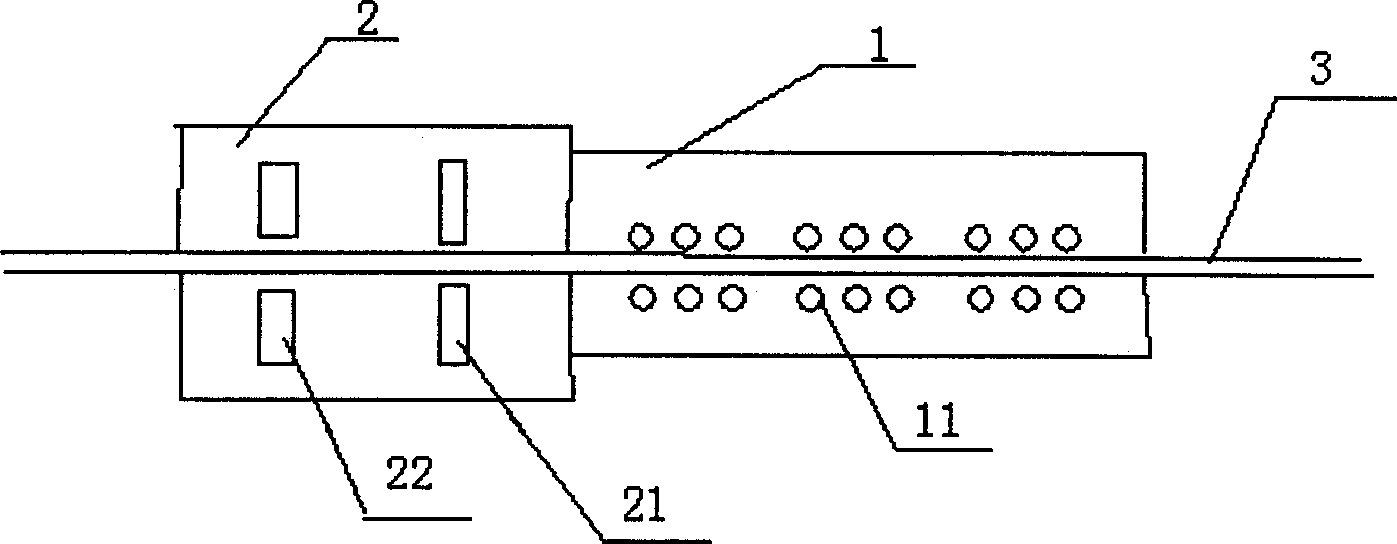

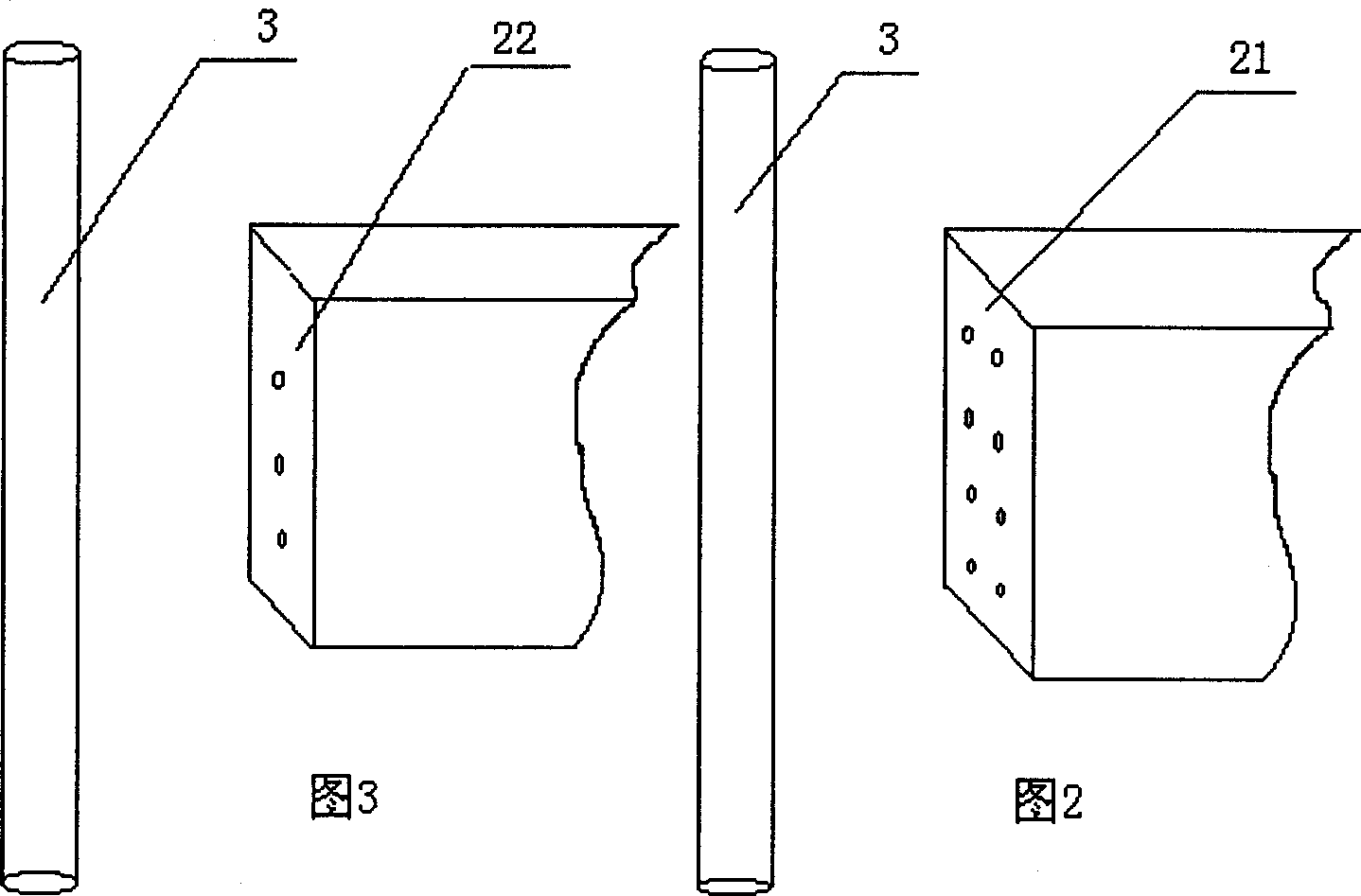

[0022] 1) The pipe and wire 3 coming out of the rolling or drawing area first enters the heating zone 1 of the special device, and the heating is divided into two stages: first enters the heating stage, the copper alloy pipe and wire 3 is heated under the action of the induction coil 11, Rapidly heat up to the temperature range of stress relief annealing at a rate of 50°C / s (300°C in this embodiment), the power of the first group of induction coils 11 is controlled in the range of 15-50kW, and the frequency is controlled in the medium-high frequency range of 5-50kHz Induction coil (power 35kW, frequency 15kHz in this embodiment); then enter the constant temperature stage, keep warm at a uniform temperature, and in the constant temperature stage induction coil 11 adopts a medium and high frequency induction coil, its power is all controlled in the range of 15 ~ 40kW, and the frequency is controlled at 5 ~50kHz range (this embodiment 25kW, frequency 15kHz);

[0023] 2) Then the ...

Embodiment 2

[0031] The difference from Example 1 is:

[0032] In the present invention, gas protection (argon or nitrogen, etc.) can be applied while heating, and argon protection is applied in this embodiment; the induction coils 11 can be 3 to 6 groups.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com