System and process for preparing superpure drinking water

A technology for ultra-clean, direct drinking water, applied in chemical instruments and methods, water/sewage treatment, water/sewage multi-stage treatment, etc., to achieve the effects of less mechanical equipment and power consumption, saving washing water, and compact pool size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

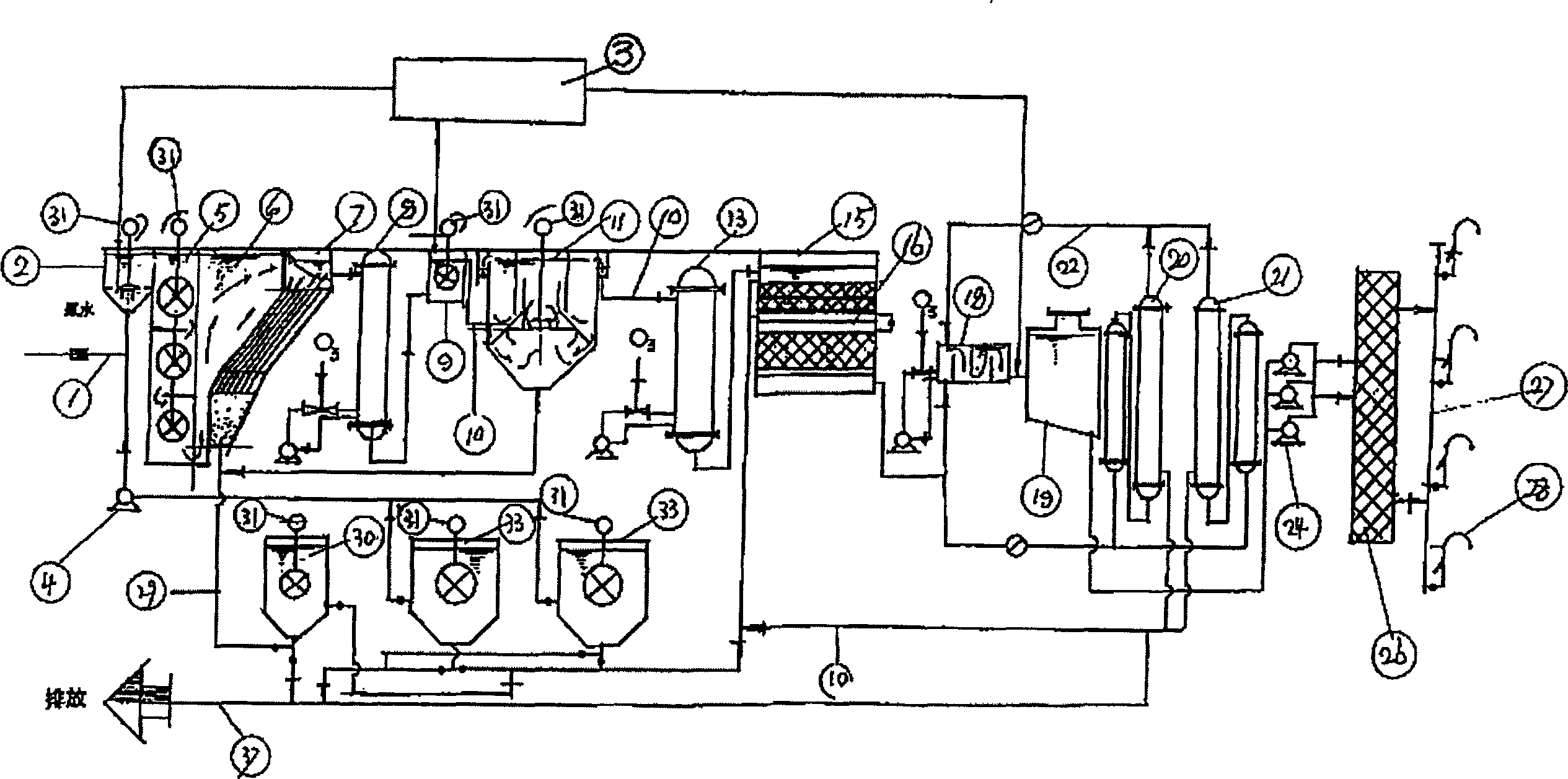

[0039] The raw water inlet pipe 1 is connected to the bottom of the flash mixer 2, and the dosing chamber 3 is connected to the flash mixer 2, the secondary flash mixer 9 and the water inlet of the water storage tank 19. The lifting device 4 is connected with the flash mixer 2 , and the upper part of the flash mixer 2 is connected with the upper part of the mechanical reaction tank 5 . The lower part of the mechanical reaction pool 5 is connected with the lower part of the Lamela separator 7, and the upper part of the Lamellar separator 7 is connected with the pre-ozone reactor 8.

[0040] The bottom of the ozone reactor 8 is connected with the bottom of the secondary flash mixer 9, and the top of the secondary flash mixer 9 is connected with an end of the water delivery pipe 10, and the other end of the water delivery pipe 10 is connected with the biochemical reaction tank 11 Water distribution tank 38 is connected. The upper general sump 52 of the biochemical reaction tank ...

Embodiment 2

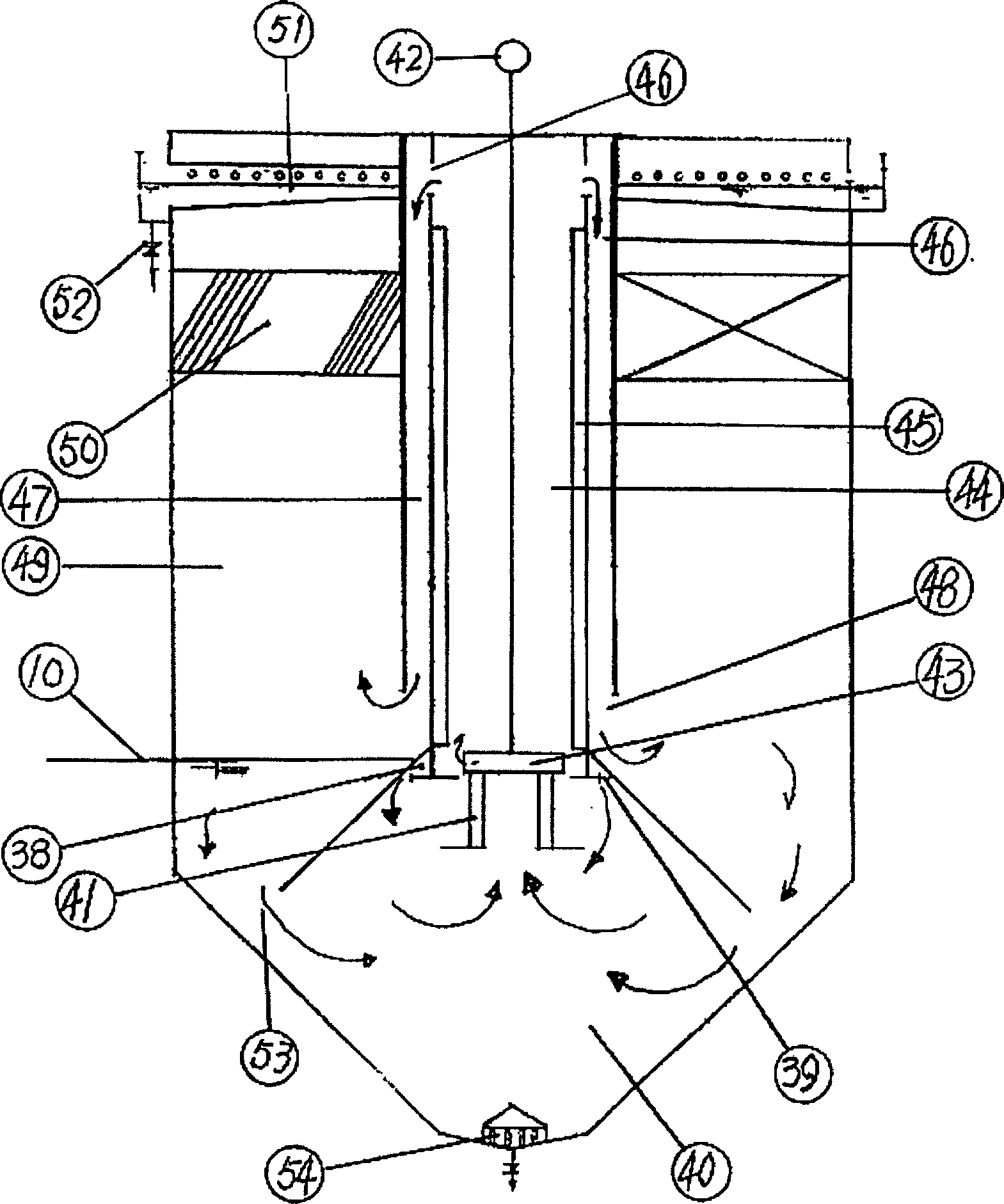

[0045] Several water distribution holes 39 are arranged around the triangular water distribution tank 38 of the biochemical pool 11 , and a primary reaction chamber 40 is arranged at the lower part of the triangular water distribution tank 38 . The upper part of the primary reaction chamber 40 is provided with an impeller 43 , and several stirring blades 41 are arranged on the impeller 43 , and the upper part of the impeller 43 is connected with a variable frequency motor transmission 42 . The upper part of the primary reaction chamber 40 is provided with a secondary reaction chamber 44 . A plurality of guide plates 45 are arranged in the secondary reaction chamber 44 , a plurality of guide holes 46 are arranged in the upper part of the secondary reaction chamber 44 , and a separation port 48 is arranged in the lower part of the guide chamber 47 . The contact separation chamber 49 is connected with the separation port 48, the upper part of the contact separation chamber 49 is ...

Embodiment 3

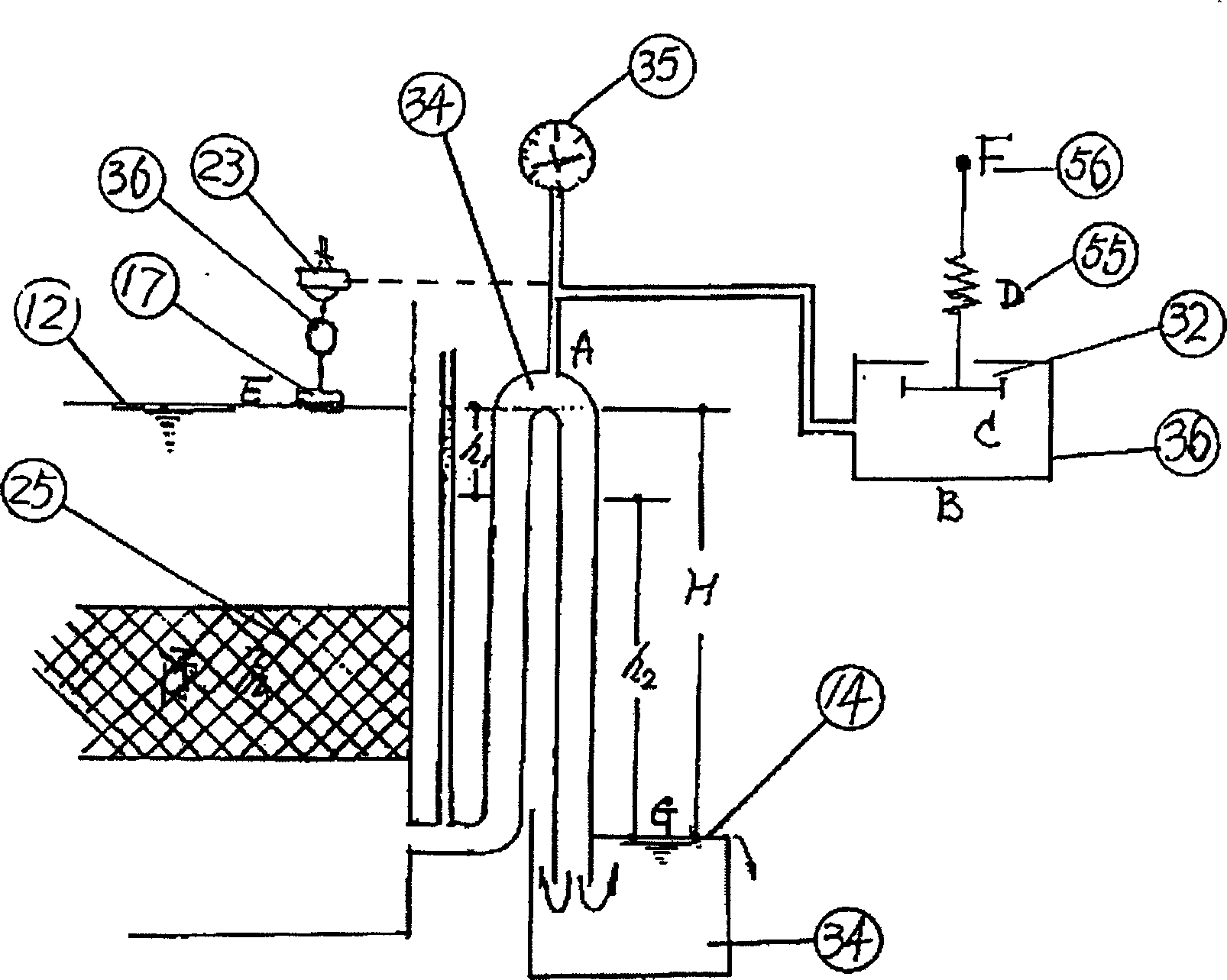

[0047] The bottom of the sand filter 15 or activated carbon filter 16 is connected to one end of an inverted U-shaped siphon pipeline 34, and the other end of the siphon pipeline 34 is inserted into the drainage tank 57, and the upper part of the siphon pipeline 34 is provided with a vacuum gauge 35 and a siphon control Device 55, vacuum gauge 35 and siphon controller 36 are connected with siphon pipeline 34 tops. The top of siphon controller 36 is provided with disc C14, and the middle part of valve disc C14 is connected with an end of spring 55, and the other end of spring 55 is connected with F point 57; The water inlet of water inlet or ultrafiltration membrane filter 20 is connected with the water inlet of nanofiltration membrane filter 21, as figure 1 , image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com