Package material for roll material and packaging method

A packaging material and packaging technology, used in packaging, wrapping paper, paper product packaging, etc., can solve the problems of environmental pollution, damage to the end of the steel plate and the surface of the plate, and poor sealing, and achieve good flexibility and rust prevention. Long time, good waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

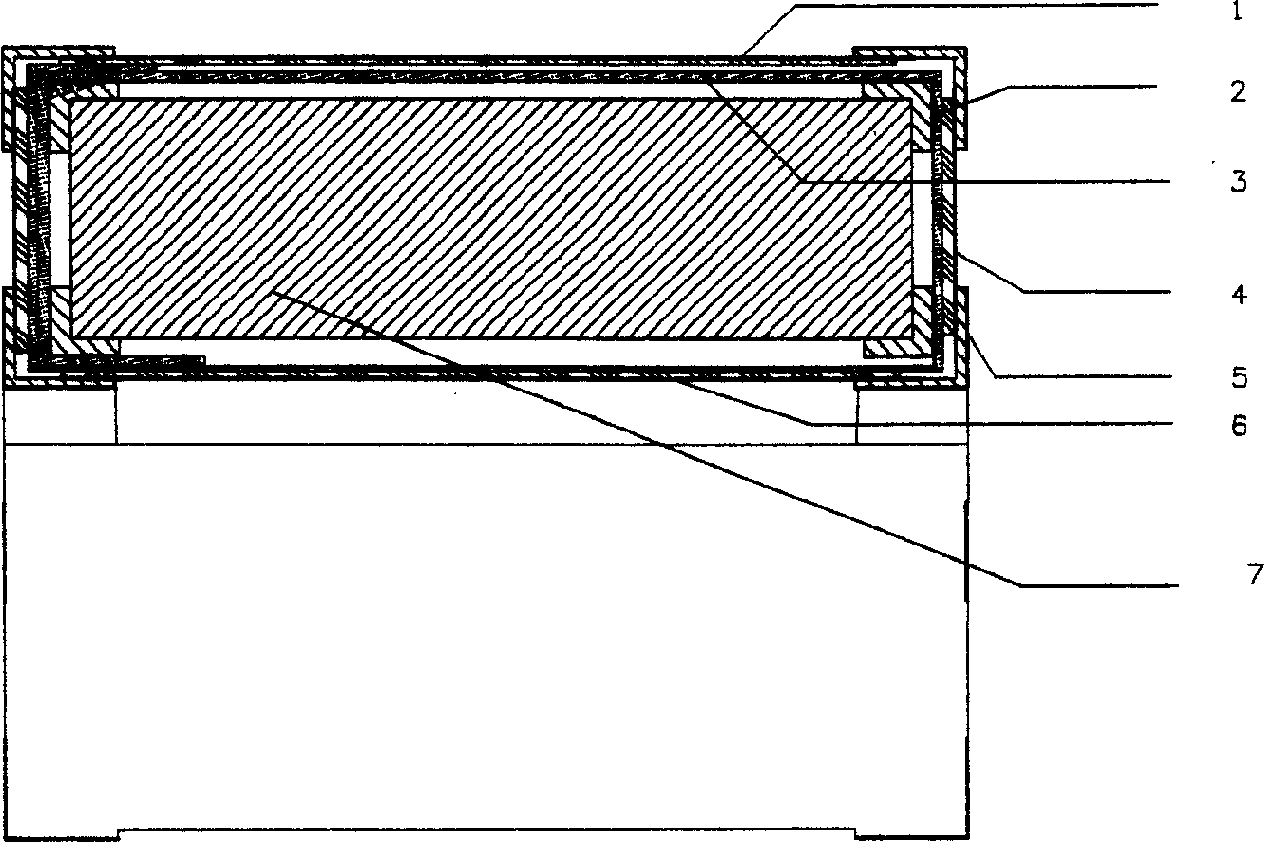

[0019] See attached figure 1 , 2 , the present invention includes industrial composite packaging film, guard plate, end guard plate and metal corner protector, using the above-mentioned materials as packaging materials, industrial packaging film 3 is a three-layer composite film formed by co-extruding a waterproof layer, a reinforcing layer and an antirust layer Packaging film, this industrial composite film 3 is co-extruded from three layers of plastics of different materials, one of which contains gas phase corrosion inhibitor and other additives, the reinforcing layer contains reinforcing agent, and the waterproof layer contains waterproofing agent, which has good Waterproof, antirust, and has high strength. In addition, a degradable masterbatch is added to the packaging film, so it is beneficial to environmental protection. After testing, at normal temperature, the tensile strength of the three-layer composite packaging film used in the present invention is greater than ...

Embodiment 2

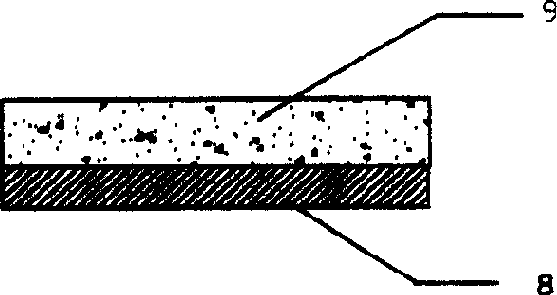

[0025] In order to improve the quality of steel packaging, meet the requirements of steel export transportation, and better meet the needs of ocean transportation, the above-mentioned guard boards and end guard boards are made of composite fiber packaging boards with waterproof performance and waterproof, rust-proof performance composite fiber packaging board, this composite fiber packaging board with waterproof and antirust performance is coated with a vapor phase antirust layer 14 on the inner side of the composite fiber packaging board with waterproof performance, such as Figure 7 shown.

[0026] The packing method that adopts above-mentioned packing material comprises the following steps (see attached Figure 5 ):

[0027] 1) The inner guard plate 12, outer guard plate 11 and end guard plate 13 made of composite fiber packaging board with waterproof and anti-rust performance are used to inner-pack the coiled material, and the inner guard plate 12 passes through the cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com