Velocity control with limited jolting

A speed control and speed technology, applied in general control system, digital control, program control, etc., can solve the problem that machine efficiency cannot be fully utilized, and achieve the effect of improving surface quality, accuracy, and contour accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

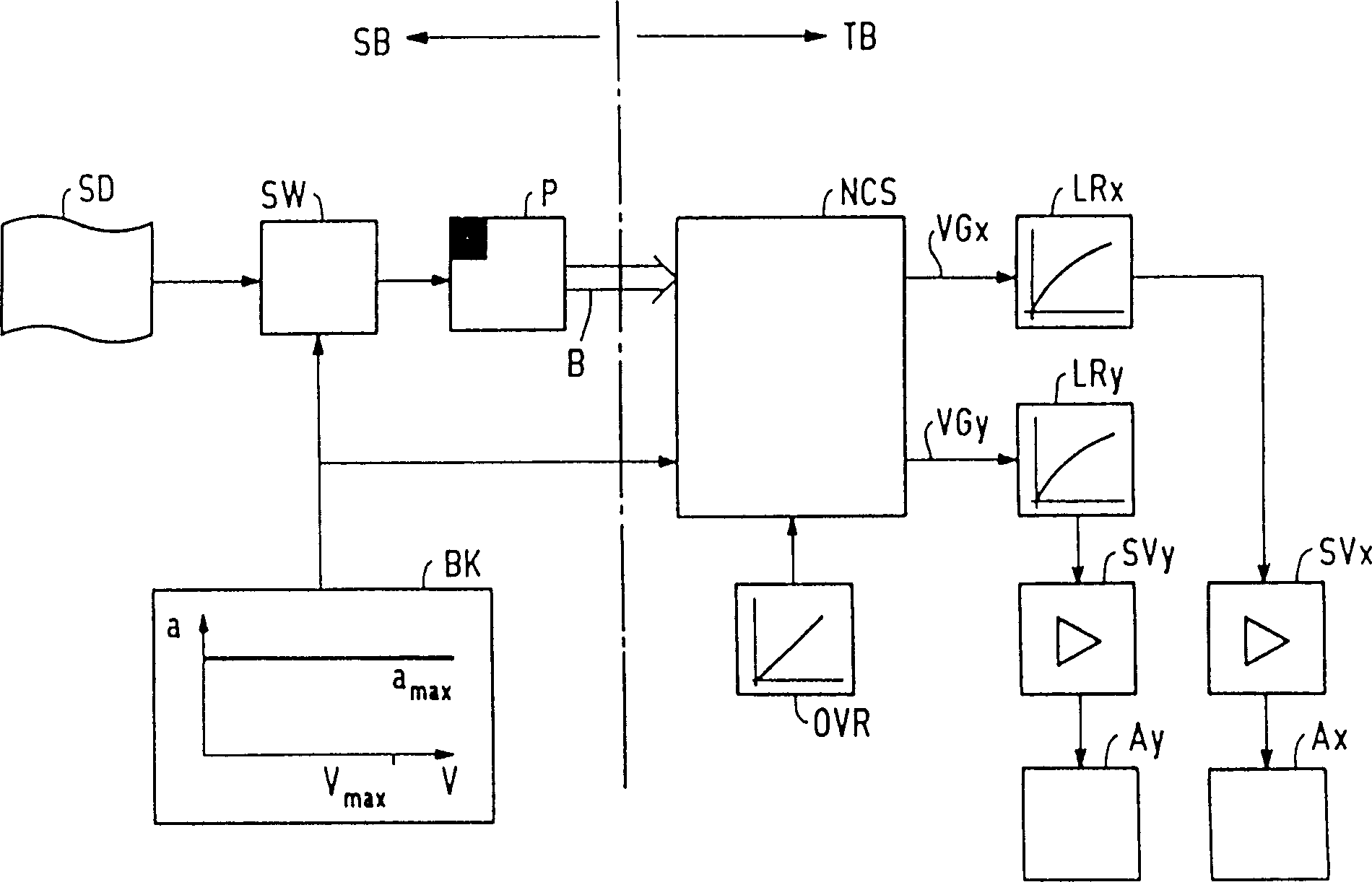

Method used

Image

Examples

Embodiment Construction

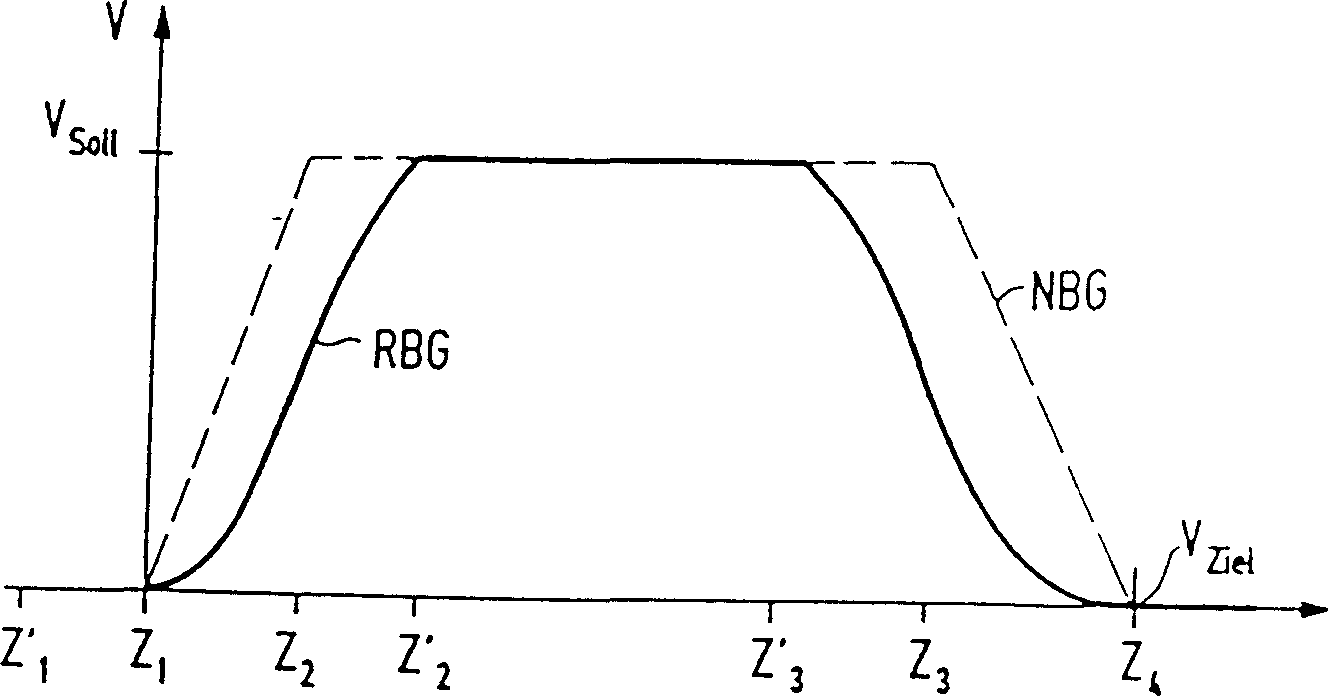

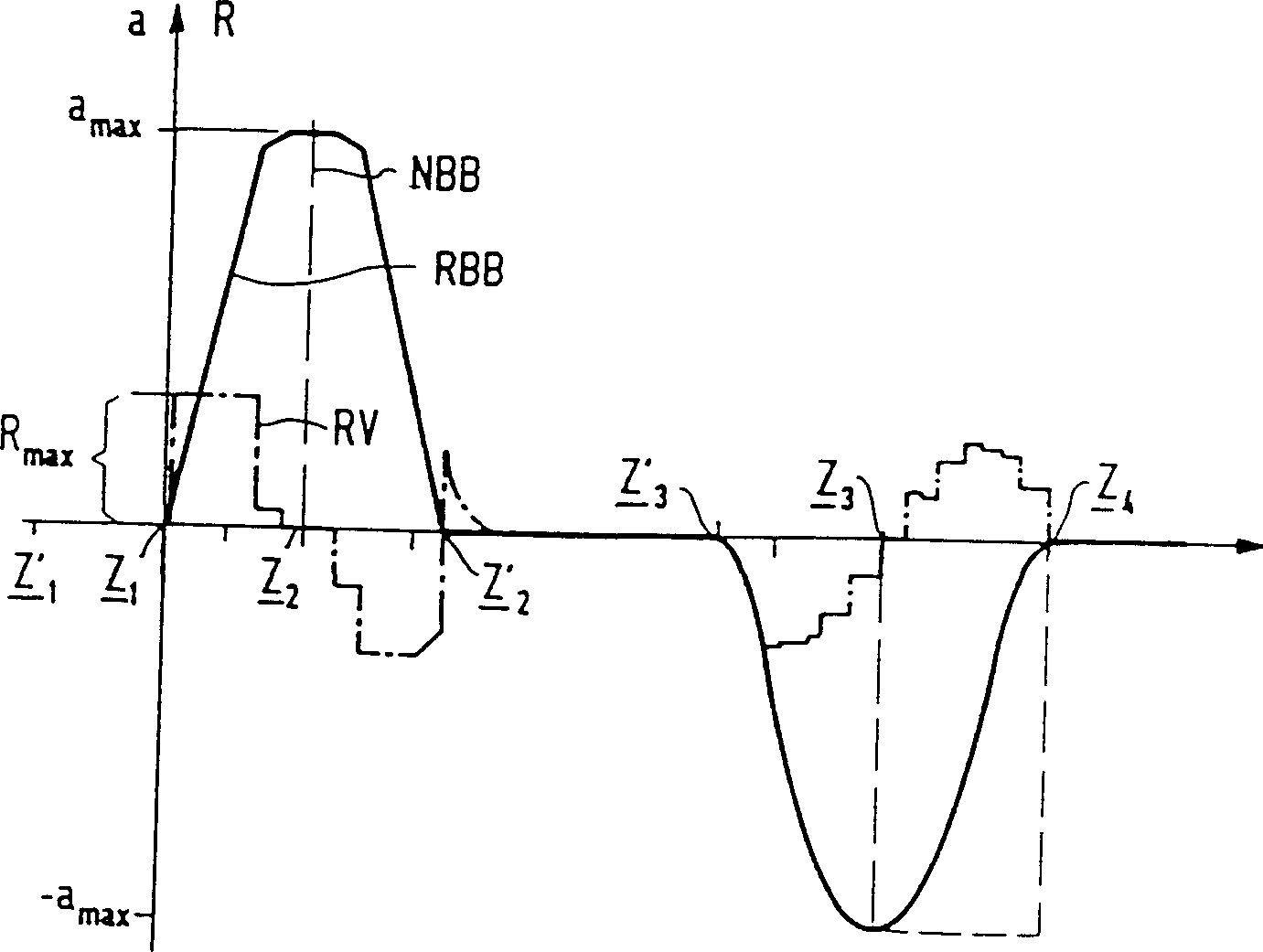

[0038] figure 1 Depicted in is a graph in which the variation of velocity V over time T is recorded. Each small segment on the abscissa represents an interpolation time scale. Two velocity values are recorded on the ordinate. One is the current preset rated speed V soll , which at point Z 2 or Z' 2 time is reached. The second speed value is the target speed V ziel , which at a certain point in time Z 4 The top is braked to reach. at startup figure 1 The two curves in represent two different speed curves, the first speed curve is achieved without using the jerk-limited speed control according to the invention, which is the non-limited speed curve NBG in dashed form. It means that the velocity at time point Z 1 Starting from zero value and increasing linearly until time point Z 2 reaches the predetermined rated speed V soll until. at time point Z 2 and Z 3 Between, the unrestricted speed curve exhibits a constant value, namely the rated speed V soll , it is ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com