Sewage treating plant with double-area gravity-elution membrane bioreactor

A membrane bioreactor, wastewater treatment technology, applied in biological water/sewage treatment, sustainable biological treatment, water/sewage multi-stage treatment, etc. Large, difficult to clean and maintain, to achieve the effect of reducing sludge concentration and membrane pollution, compact structure and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

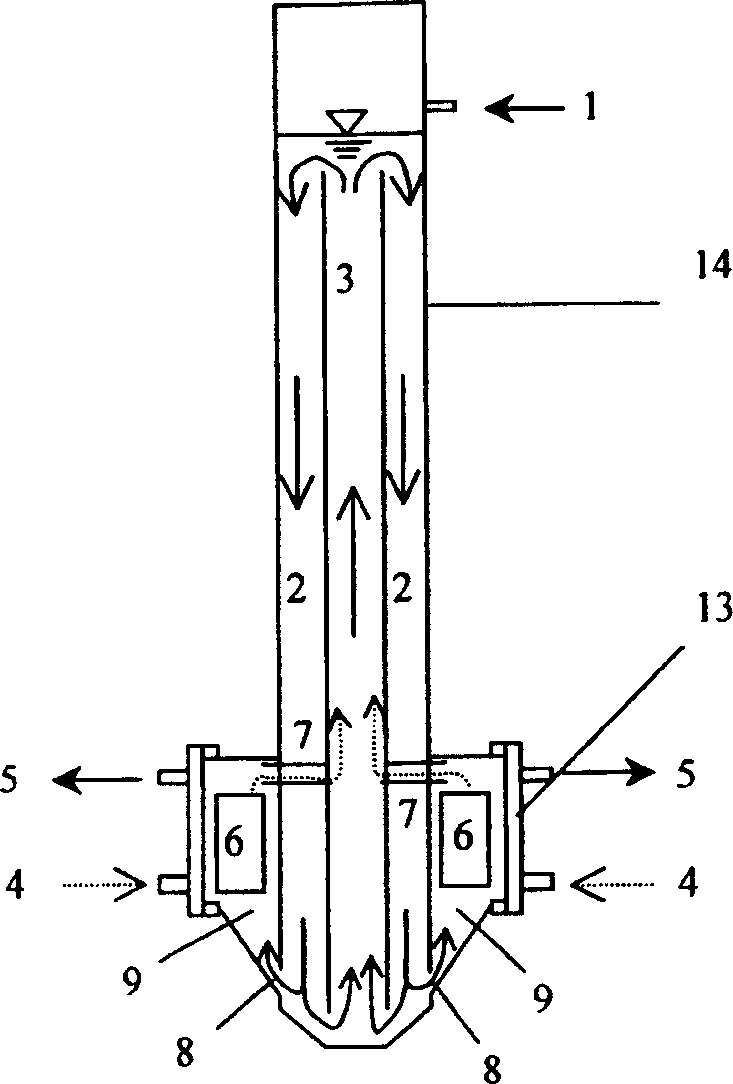

[0035] A dual-zone gravity outflow membrane bioreactor wastewater treatment equipment consists of an upflow reactor 14 and a container 13.

[0036] The upflow reactor is a biochemical reaction zone 2, and a central pipe 3 is installed in the upflow reactor, and a water inlet 1 is opened on the upper side wall of the reactor.

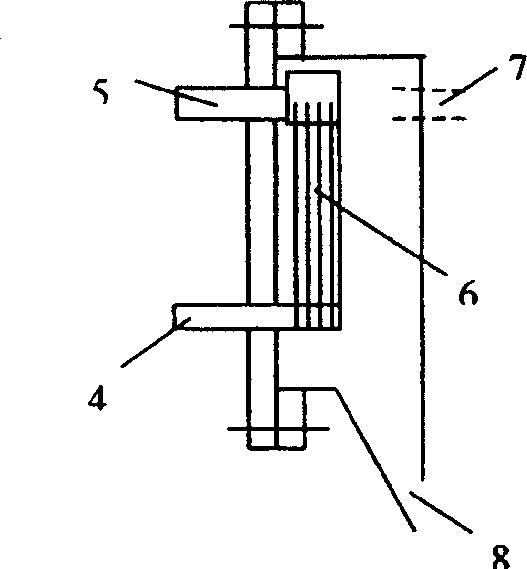

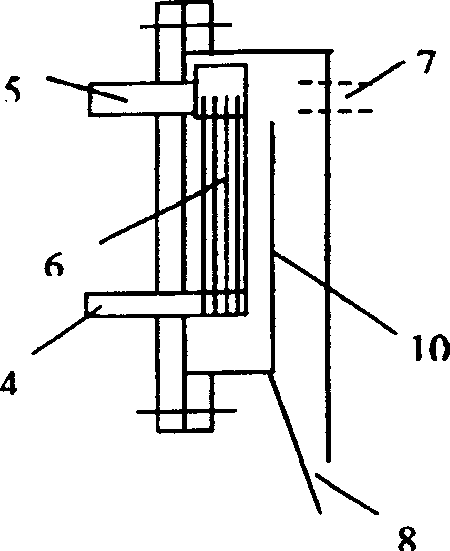

[0037] The container is a solid-liquid separation zone 9, a membrane module 6 is installed in the container 13, the bottom of the membrane module 6 is provided with an aeration tube, and a partition 10 is arranged between the membrane module and the outer wall of the upflow reactor; The upper side wall of the container has an air inlet 4, and a water outlet 5 is arranged on the upper part of the air inlet, and a mixed solution inlet 8 is arranged on the lower part of the container, and the bottom end of the upflow reactor communicates with the container; The top passes through the side wall of the upflow reactor, and a connecting pipe 7 connecting the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com